Cokemaking projects

Coke making research

Coke provides physical support for the ferrous burden in the blast furnace, as well as providing a source of permeability, heat and the reducing environment necessary for the production of iron. For coal producers and coke manufacturers, understanding the performance of different coals and blends during coking and ironmaking process is critically important for efficient utilisation of coal resources.

Centre researchers conduct research for fundamental understanding of coal to coke transformation and evaluate the behaviour of different coals during coke formation as well as coke performance in blast furnace. A focus of research is to understand the impact of parent coal properties in physicochemical structure and strength of coke using innovative methodologies and purpose-built facilities. Some capabilities include:

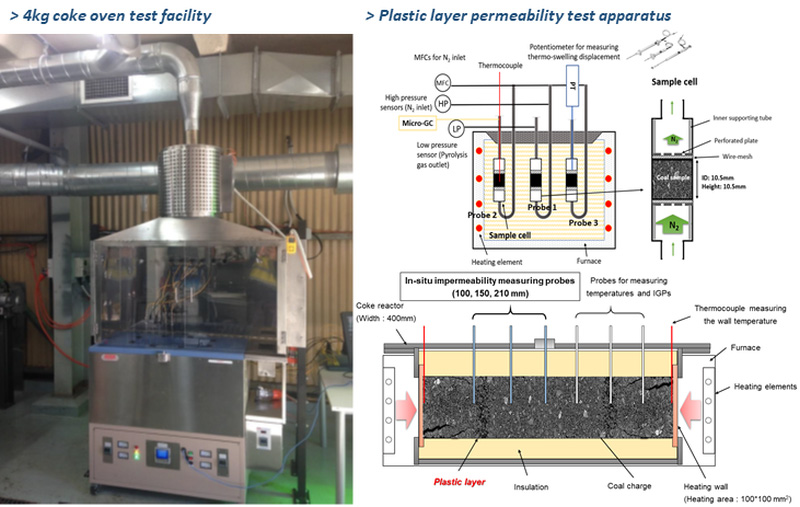

(a) In-situ investigation of coking phenomena

In collaboration with researchers at NIER, centre researchers utilise a unique 4 kg laboratory-scale double-heated wall coke oven that simulates the heating conditions inside industrials ovens. The research focuses on fundamental investigation of the thermoplastic behaviours and subsequent coking behaviours of coking coal during the coking process.

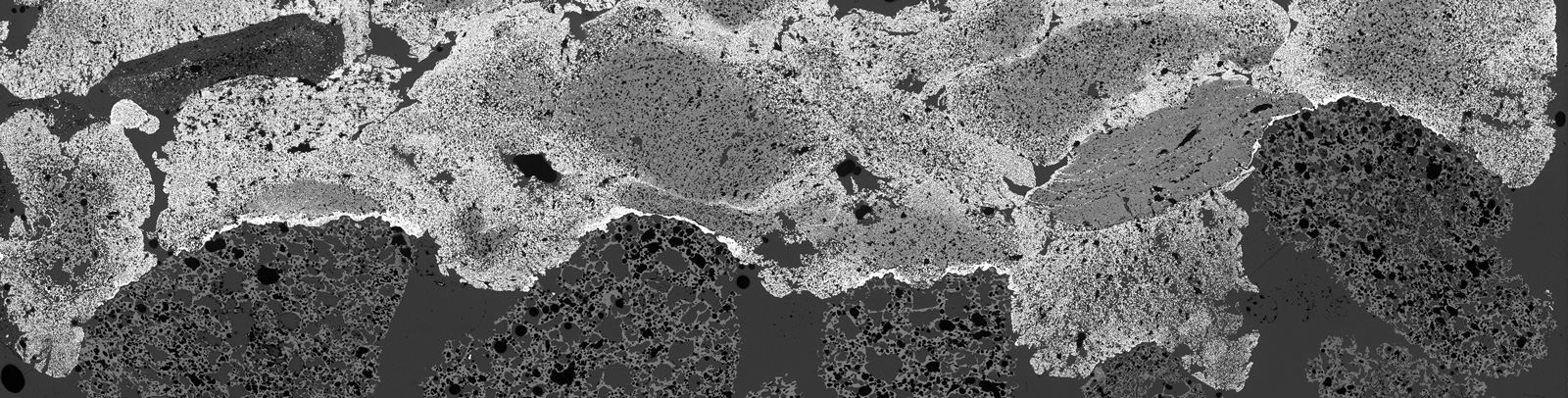

(b) Coke microstructure and microtexture analysis

Centre researchers have developed innovative means to investigate the evolution of coal and coke structure during coking as well as under simulated blast furnace conditions. Combining real-time sampling techniques and innovative analysis methods such as micro-CT analysis, the team has improved the fundamental understanding of coke structure formation and impacts on coke strength and reactivity.

(c) Mechanical properties of coke

Collaborating with academic and industry partners, centre researchers have developed methodologies for evaluation of mechanical properties of coke under simulated blast furnace reaction conditions. These include high temperature coke strength analysis (in collaboration with researchers at the University of New South Wales and ANSTO) as well as ambient and high-temperature tribology tests (in collaboration with researchers at the University of Wollongong). These studies have improved our understanding of coke microtextural boundary properties- often a major source of weakness in coke.

The University of Newcastle acknowledges the traditional custodians of the lands within our footprint areas: Awabakal, Darkinjung, Biripai, Worimi, Wonnarua, and Eora Nations. We also pay respect to the wisdom of our Elders past and present.