Associate Professor Tom Honeyands

Associate Professor

School of Engineering

- Email:tom.a.honeyands@newcastle.edu.au

- Phone:0240339216

Striking while the iron is hot

A human story behind the headlines, Professor Tom Honeyands is seeking to put science behind the mining downturn.

The sun may be setting on the west's golden iron age, but Professor Tom Honeyands maintains there's no need to panic – if the industry can work smarter, not harder. Indeed, while Australia is uniquely vulnerable to China's economic crisis, it's also uniquely placed to compete for the attention of its struggling steel producers.

"The quality of iron ore and the knowledge to use it efficiently has really come to the fore," he asserts.

"The countries that do this best will do much better in the current circumstances."

Though sparking a wrestling match between mining's heavyweights and policy makers, and just about everyone else, Tom concedes the commodities slump dually allows scientists to be at the coalface of cost minimisation and value-adding efforts. A metallurgical specialist with more than 26 years' experience in consulting, research and process engineering, he is aiming to boost the viability and productivity of our nation's careworn minerals sector.

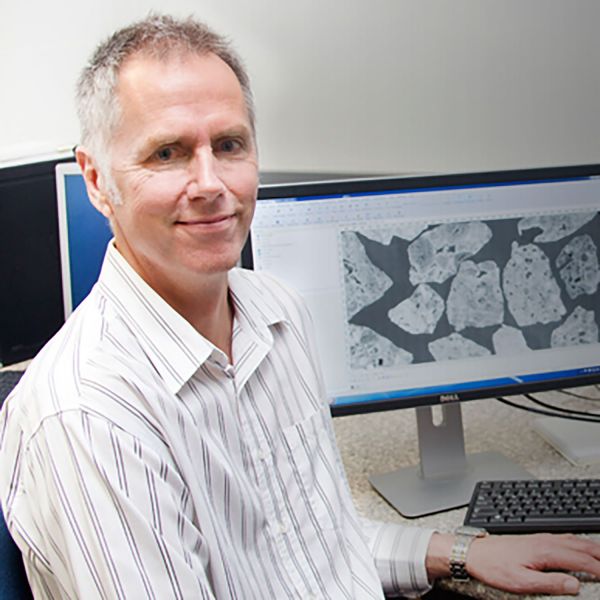

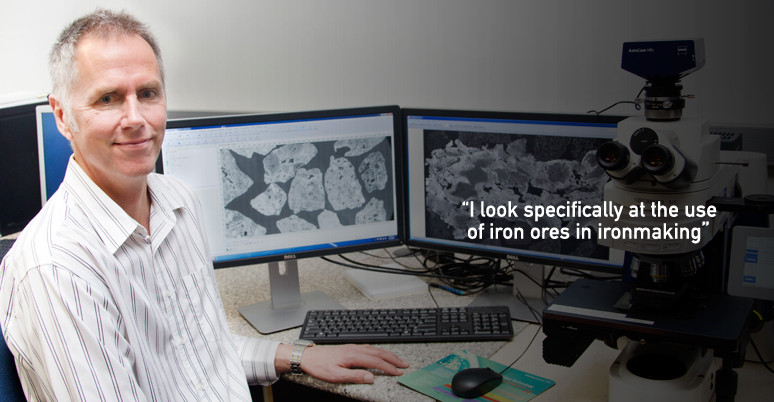

"I look specifically at the use of iron ores in ironmaking," the New Zealand native explains.

"The goal is to cement an understanding of its properties and how they behave in different processes, such as sintering and blast furnace ironmaking."

Iron clad beginnings

Tom's research career began in 1991, when he undertook a PhD at the University of Newcastle. Building a full-scale model of steel caster using perspex and water, he used the three-year probe to examine the fluid mechanics of thin slab caster moulds.

"With this type of casting, the same volume of fluid goes into a much smaller area, which causes oscillating waves to form on the surface of the caster," the chemical expert elaborates.

"This causes product defects."

"I discovered you can use electromagnetic breaking to stop them from happening, however."

"I relied on computational fluid dynamics to explore the magnetic forces at play."

Signing on to become a Research Engineer at the then BHP Central Research Laboratory after receiving his award in 1994, Tom sought to expand his knowledge of these and other ironmaking processes.

"My most memorable and challenging task was probably at Port Hedland in Western Australia," he muses.

"I was part of the technical team working to improve the operability of the Boodarie Iron, hot briquetted iron plant."

"I led an investigation into the sintering of hot, partially reduced iron ore as it flowed between fluidised bed reactors."

"We had access to specialist laboratory equipment that simulated the high-temperature, high pressure process," he comments.

"Cooling the first reactor was found to be beneficial – dense shells of metallic iron were no longer formed on the iron, which allowed reduction to proceed and made the ore less sticky."

"This discovery led to the creation of a patented test methodology for the sticking of particulate solids."

"It was subsequently licensed to POSCO, a South Korean steelmaking giant."

The big picture

In September 2006, Tom became the Director of Creative Process Innovation, a small, highly specialised consultancy business based in the Hunter. Concentrating on research project management and technical marketing, the accomplished academic looked to foster industry growth both locally and overseas.

"I also developed Marx' Value in Use (VIU), which is a mathematical model of smelting and sintering processes that quantifies the value, or lack of value, of iron ore," he adds.

Teaming up with the University of Newcastle, Auckland University, the CSIRO and the "who's who" of major global mining companies in 2012, Tom endeavoured to advance the science and engineering that underpins measurement of the transportable moisture limit (TML) for iron ore fines through the AMIRA P1097 project.

A ship's rocking motion can potentially lead to bulk cargoes behaving like a liquid, compromising vessel safety. The P1097 project selected and modified a TML test specifically calibrated to iron ore fines shipment, contributing to the new International Maritime Organisation schedule for iron ore fines as well as a draft international standard.

Experiments and exports

Tom joined the University of Newcastle in October 2015, opting to take on leadership roles at its Centre for Ironmaking Materials Research (CIMR) and the "properties and end use stream" of its ARC Research Hub for Advanced Technologies for Australian Iron Ore. Using small-scale laboratory furnaces and microscopy techniques, he's seeking to mimic and better understand sintering and ironmaking processes.

"We're currently simulating smelting in a real blast furnace at small scale. The critical part is the soft melting zone, which controls the productivity of the whole process," Tom shares.

"We're studying the interactions that occur when you charge lump iron ore in with the sinter and pellets."

"The primary goal is to help customers get the best out of these products."

In the former area, however, Tom is mostly interested in structural changes.

"The structure of the iron ore bed changes quite dramatically during the sintering process, and in so doing, determines the quality of the sinter and its performance in the blast furnace."

Funded by BHP Billiton and the ARC, Tom is set to run an interstate study on these complex changes in early 2016.

"We'll be using the Synchrotron in Melbourne to do x-ray CT scans and build up a 3D picture of the structure – how strong it will be and how easily it will reduce," he clarifies.

"We'll also be using sinter pot experiments, which are pilot-scale simulation devices housed in the CSIRO in Queensland and Zhejiang University in China."

Find out more

Striking while the iron is hot

The sun may be setting on the west’s golden iron age, but Professor Tom Honeyands maintains there’s no need to panic – if the industry can work smarter, not har

Career Summary

Biography

Prior to joining the University of Newcastle in 2015, I spent 20 years working in an industrial R&D environment and 6 years as a metallurgical consultant.

While at BHP Billiton Research, I worked on a range of industrial research spanning continuous casting of steel; steelmaking; manufacturing, transport and use of direct reduced iron; manganese smelting; iron ore geometallurgy use in iron and steelmaking.

A key focus of the iron ore research was to define a link between fundamental iron ore properties and their performance in ironmaking processes.

While working for Creative Process Innovation, I developed the Marx Value in Use (VIU) model which has been applied on more than 35 VIU studies for major and junior iron ore miners. I also led the AMIRA P1097 project on transportable moisture limit (TML) of iron ores and the P1150 project on moisture measurement and control for iron ore conveyor systems.

Research Expertise

- Characterisation of ironmaking raw materials relevant to their end-use (e.g., iron ore for sintering, iron ore sinter, lump and pellets for blast furnace ironmaking)

- Applied research with focus on understanding process fundamentals (e.g., the iron ore sintering and FINMET processes)

- Formulation of research programs to achieve desired, tangible outcomes (e.g., results that can be used in technical marketing and/or solve commercial-scale problems)

Teaching Expertise

Delivered in-house iron and steelmaking training to Iron Ore miners (50 courses and almost 800 trainees)

Qualifications

- Doctor of Philosophy, University of Newcastle

- Bachelor of Engineering (Honours), University of Auckland - NZ

Keywords

- Blast Furnace Ironmaking

- Direct Reduced Iron

- Iron Ore Geometallurgy

- Iron Ore Properties

- Iron Ore Sintering

- Value In Use Modelling

Fields of Research

| Code | Description | Percentage |

|---|---|---|

| 401999 | Resources engineering and extractive metallurgy not elsewhere classified | 100 |

Professional Experience

UON Appointment

| Title | Organisation / Department |

|---|---|

| Associate Professor | University of Newcastle School of Engineering Australia |

Professional appointment

| Dates | Title | Organisation / Department |

|---|---|---|

| 1/9/2009 - 31/8/2015 |

Director Creative Process Innovation provides an independent metallurgical consulting service, focussed on research project management, technical marketing and process improvement. |

Creative Process Innovation Australia |

| 1/6/2006 - 31/8/2009 |

Iron Ore Research Leader The Iron Ore Team was focused on the areas of geo-metallurgy and technical marketing for BHP Billiton’s Iron Ore Business. |

BHP Billiton Innovation Pty Ltd |

| 1/3/2002 - 31/5/2006 |

Serior / Principal Research Engineer Process analysis and control and Manganese Technical Marketing team leader. Team Leader for a group responsible for making incremental improvements to BHP Billiton operations worldwide, primarily in the areas of pyrometallurgy, process optimization, process modeling and process control. |

BHP Billiton Research Labs |

| 1/6/1995 - 28/2/2002 |

Research Engineer - Boodarie Iron Process Support and Technical Marketing Leader of a team responsible for technical marketing of Boodarie Iron (hot briquetted iron), in the Asian Market. The team also improved operability of the processing plant itself |

BHP Billiton Research Labs |

Publications

For publications that are currently unpublished or in-press, details are shown in italics.

Conference (89 outputs)

| Year | Citation | Altmetrics | Link | |||||

|---|---|---|---|---|---|---|---|---|

| 2026 |

Longbottom R, Aladejebi O, Nguyen T, Honeyands T, Mitra S, Bolan N, Cheng S, Monaghan B, 'Phosphorus Segregation and wetting in steel making slag' (2026)

|

|||||||

| 2026 |

Nguyen T, Garlick C, Singh T, Taimullah A, O'Dea D, Honeyands T, 'Heat transfer model for laboratory-scale brushed arc electric smelting furnace' (2026)

|

|||||||

| 2025 |

Lu G, Khoshk Rish S, Lomas H, Tahmasebi A, Honeyands T, 'Mechanical strength and microstructure formation of ferro-coke for low-carbon blast furnace ironmaking - International Conference on Sustainable Cokemaking and Ironmaking (ICSCI 2025), 16-19 Mar 2025, Newcastle, Australia' (2025)

|

|||||||

| 2025 |

Barrett N, Copland E, O’Dea D, Honeyands T, 'Softening and Melting Behaviour of Ferrous Burdens in Gas Compositions Representative of Hydrogen Enriched Blast Furnace Operation', Proceedings Icsti 2025 10th International Congress on the Science and Technology of Ironmaking, 965-970 (2025)

|

|||||||

| 2025 |

Wang R, Cole M, Tremain P, Honeyands T, 'H2 Reducibility and Sticking Behaviour of Australian Ores in Fluidized Bed Reduction', Proceedings Icsti 2025 10th International Congress on the Science and Technology of Ironmaking, 1070-1074 (2025)

|

|||||||

| 2025 |

Honeyands T, Garlick C, Singh T, Paymooni K, Barrett N, Nguyen T, O'Dea D, 'Findings from Laboratory-scale Electric Smelting Furnace Experiments', Findings from Laboratory-scale Electric Smelting Furnace Experiments, 971-975 (2025)

|

Open Research Newcastle | ||||||

| 2025 |

Paymooni K, Garlick C, O'Dea D, Gadd A, Honeyands T, 'Emission Abatement Potential of DRI Shaft Furnace Integrated with ESF-BOF Process Route', 1232-1237 (2025)

|

Open Research Newcastle | ||||||

| 2024 |

Chowdhury R, Mitra S, Evans G, Honeyands TA, Monaghan BJ, Scimone D, 'An investigation of potential wear occurring on refractory lining and coating formation- a remedy of wear in a basic oxygen steelmaking furnace using CFD modelling', 12th International Conference of Molten Slags, Fluxes and Salts. MOLTEN 2024 Proceedings, 781-793 (2024) [E1]

|

|||||||

| 2024 |

Barrett N, Mitra S, Copland E, O’Dea D, Honeyands T, 'Visualisation of calculated thermodynamic properties by integration of FactSage™ with SEM-EDS element maps', 12th International Conference of Molten Slags, Fluxes and Salts. MOLTEN 2024 Proceedings, 625-634 (2024) [E1]

|

|||||||

| 2023 |

Singh T, Mitra S, Aladejebi O, O'Dea D, Honeyands T, 'Effect of -1 mm particle size fraction on JPU permeability and granulation characterisation', 265-273 (2023) [E1]

|

Open Research Newcastle | ||||||

| 2023 | Aladejebi O, Mitra S, Singh T, Pinson DJ, Chew SJ, Honeyands T, 'Behaviour of Iron Ore Granules: Laboratory and Commercial Sinter Plant Granulation', Iron Ore Conference 2023. Proceedings, 524-534 (2023) [E1] | Open Research Newcastle | ||||||

| 2022 |

Singh T, Matthews L, Jung I-H, Mitra S, O'Dea D, Honeyands T, 'Evolution of mineral phases during iron ore sintering' (2022)

|

|||||||

| 2021 |

Sukhram M, Lefebvre K, Aubry N, Cameron I, Ellis B, Liu X, Honeyands T, 'Top gas recycling revisited to reduce blast furnace CO2 emissions', AISTech: - Proceedings of the Iron and Steel Technology Conference. Volume 1, 2021-June, 1432-1444 (2021) [E1]

|

Open Research Newcastle | ||||||

| 2021 |

Nguyen TBT, Harvey T, Honeyands T, Matthews L, O'Dea D, 'Sinter analogues mineralogy by different heating conditions', Iron Ore Conference 2021. Sustainability in a Changing World, 700-706 (2021) [E1]

|

Open Research Newcastle | ||||||

| 2021 |

Singh T, Mitra S, O'Dea D, Honeyands T, 'Analyses of pressure drop in high temperature zone during iron ore sintering', Iron Ore Conference 2021. Sustainability in a Changing World, 707-714 (2021) [E1]

|

Open Research Newcastle | ||||||

| 2021 |

Barrett N, Zulli P, O'Dea D, Mitra S, Honeyands T, 'Replacement of Pulverised Coal Injection (PCI) with hydrogen and its impact on blast furnace internal conditions', Iron Ore Conference 2021. Sustainability in a Changing World, 65-71 (2021) [E1]

|

Open Research Newcastle | ||||||

| 2020 |

Chowdhury R, Mitra S, Hoque MM, Evans G, Honeyands T, Monaghan B, Scimone D, 'Weber Number Effect on Molten Droplet Impingement on a Flat Substrate', Chemeca 2020: Renew, Sustain, Disrupt, Advance, 118-131 (2020) [E1]

|

Open Research Newcastle | ||||||

| 2019 |

Liu X, Honeyands T, Evans G, Chen J, O'Dea D, 'Chemical Interaction between Basic Sinter and Newman Blend Lump Analogues', Proceedings Iron Ore 2019, 872-879 (2019) [E1]

|

Open Research Newcastle | ||||||

| 2019 |

Harvey T, O'Dea D, Evans G, Honeyands T, 'Influence of sintering conditions on the reducibility of iron ore sinter analogues', Proceedings Iron Ore 2019, 862-871 (2019) [E1]

|

Open Research Newcastle | ||||||

| 2019 |

Singh T, Honeyands T, Mitra S, Evans G, O'Dea D, 'Measured and Modelled Air Flow Rates during the Iron Ore Sintering Process: Green and Sintered Beds', Proceedings Iron Ore 2019, 156-165 (2019) [E1]

|

Open Research Newcastle | ||||||

| 2017 | Zhou M, Zhou H, Honeyands TA, 'Tensile Strength and Shear Strength Properties of the Adhering Layer of Granules in Iron Ore Sintering', Iron Ore 2017, 117-122 (2017) [E1] | Open Research Newcastle | ||||||

| 2017 | Honeyands TA, Manuel JR, Matthews L, O'Dea D, Pinson DJ, Leedham J, Monaghan BJ, Li H, Chen J, Hayes PC, Donskoi E, Pownceby MI, 'Characterising the Mineralogy of Iron Ore Sinters - State of the Art in Australia', Iron Ore 2017, 49-60 (2017) [E1] | Open Research Newcastle | ||||||

| 2017 | Li C, Moreno-Atanasio R, O'Dea D, Honeyands T, 'Variation in property parameters of iron ore granulated mix with moisture content', Iron Ore 2017, 79-84 (2017) [E1] | Open Research Newcastle | ||||||

| 2017 | Liu X, Honeyands T, O'Dea D, Li G, 'New Techniques to Measure Softening and Melting Properties of Mixed Burdens of Lump Ore and Sinter', Proceedings of the 11th CSM Congress (2017) [E1] | Open Research Newcastle | ||||||

| 2017 | Godel B, Ellis B, O'Dea D, Honeyands TA, Harvey T, 'Digital rocks for Iron Ore sinters: toward a 3D quantification of sinter textures', Iron Ore 2017, 529-533 (2017) [E1] | Open Research Newcastle | ||||||

| 2017 |

Harvey T, O'Dea D, Evans G, Godel B, Honeyands TA, 'Highlighting Key Features of the Pore Structure of Iron Ore Sinter using Mercury Intrusion Porosimetry and X-ray Computed Tomography', Iron Ore 2017, 39-47 (2017) [E1]

|

Open Research Newcastle | ||||||

| 2016 |

Andrews L, Evans G, Honeyands TA, 'Qualitative study of melt composition on reshaping behaviour of suspended model iron ore sinter configurations', Chemical Engineering - Regeneration, Recovery and Reinvention (CHEMECA 2016), 769-779 (2016) [E1]

|

Open Research Newcastle | ||||||

| 2016 | Li C, Zhao J, Honeyands T, Moreno-Atanasio R, 'Variables influencing the angle of repose of iron ore granulated mix', CHEMECA 2016: Chemical Engineering - Regeneration, Recovery and Reinvention, 622-630 (2016) [E1] | Open Research Newcastle | ||||||

| 2016 |

Holmes RJ, Williams K, Honeyands T, Orense R, Roberts A, Pender M, McCallum D, Krull T, 'Bulk commodity characterisation for transportable moisture limit determination', Proceedings of the XXVIII International Mineral Processing Congress (IMPC 2016), 2016-September (2016) [E1]

|

Open Research Newcastle | ||||||

| 2015 |

Williams K, Honeyands TA, Holmes R, Orense R, Roberts A, Pender M, McCallum D, Krull T, 'Maritime Bulk Cargo Transportable Moisture Limit Requirements for Iron Ore Shipments', Iron Ore 2015: Maximising Productivity. Proceedings, 399-410 (2015) [E1]

|

Open Research Newcastle | ||||||

| 2011 |

Honeyands T, Jelenich L, 'Calculating the value of iron ores in ironmaking and steelmaking', Iron Ore 2011 Proceedings, 431-436 (2011)

At present we are witnessing large investments in the iron ore industry, fuelled by demand from Asia. At the same time, there is a changing landscape in pricing of iron... [more] At present we are witnessing large investments in the iron ore industry, fuelled by demand from Asia. At the same time, there is a changing landscape in pricing of iron ores, with the recent demise of the benchmark system and the evolution of market based index pricing systems. From a customer perspective, it is the behaviour of iron ores in downstream processing that gives them their value; their impact on the sintering or pelletising process and subsequently blast furnace ironmaking. It is therefore important to consider this value when developing projects, making mine planning/cut-off grade decisions, and in setting quality price differentials. This paper describes the use of the Marx value in use (VIU) model to quantify the downstream value of iron ores. The Marx model consists of heat and mass balance modules for sintering, pelletising and a rigorous two-stage heat and mass balance model of blast furnace ironmaking. Mass balance and cost models are applied for steelmaking, casting and rolling. The use of a heat and mass balance allows accurate comparison of the impact of raw material properties on blast furnace operation. The impact of minor elements, such as alumina, silica and phosphorus, and metallurgical properties on ironmaking is described, and examples given for the relative value of haematite, Marra Mamba, and channel iron deposit (CID) ores.

|

|||||||

| 2009 |

Chen C-L, Zhang L, Steven W, Sun S-Y, Sharif J, Tom H, 'Modelling the Effect of MnO on Slag Properties and Mn, Si and S Distribution in Blast Furnaces', JOURNAL OF IRON AND STEEL RESEARCH INTERNATIONAL, 16, 1116-1120 (2009)

|

|||||||

| 2009 |

Zhang ZW, Hu XM, Du HJ, Honeyands TT, Lin LQ, 'MAC lump properties study and plant performance at baosteel stainless steel', Proceedings of the 5th International Congress on the Science and Technology of Ironmaking, 696-700 (2009)

|

|||||||

| 2004 |

Caffery G, Rafiei P, Honeyands T, Trotter D, 'Understanding the melting characteristics of HBI in iron and steel melts', Aistech Iron and Steel Technology Conference Proceedings, 1, 503-516 (2004)

The experiments conducted and the techniques used to analyze the melting rate before discussing the implications on the briquette melting rate were described. The exper... [more] The experiments conducted and the techniques used to analyze the melting rate before discussing the implications on the briquette melting rate were described. The experimental results show that the cylinders of hot briquetted iron (HBI) melt much faster than steel cylinders, due to the higher C and FeO content of the briquettes. It was observed that the higher C content tended to increase the driving force for melting, could lead to grains of DRI detaching from the bulk of the briquette during melting, and led to greatly enhanced heat transfer due to formation of CO gas. The inverse heat transfer analysis had been completed and had shown that the bath carbon content was important in determining the overall melting time.

|

|||||||

| 2001 | Gray J, Sahajwalla V, Honeyands T, 'Reoxidation of laboratory hot briquetted iron', 84TH STEELMAKING CONFERENCE PROCEEDINGS, 84, 735-745 (2001) | |||||||

| 2001 |

Gray J, Sahajwalla V, Honeyands T, 'Reoxidation of laboratory hot briquetted iron', 60TH IRONMAKING CONFERENCE PROCEEDINGS, 60, 993-1003 (2001)

|

|||||||

| 1999 |

Brent AD, Mayfield PLJ, Honeyands TA, 'The Port Hedland FINMET (R) project - Fluid bed production of high quality virgin iron for the 21st century', ICARISM '99: PROCEEDINGS OF THE INTERNATIONAL CONFERENCE ON ALTERNATIVE ROUTES OF IRON AND STEELMAKING, 99, 111-114 (1999)

|

|||||||

| Show 86 more conferences | ||||||||

Journal article (55 outputs)

| Year | Citation | Altmetrics | Link | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2026 |

Chowdhury R, Evans G, Honeyands T, Monaghan BJ, Scimone D, Mitra S, 'Spreading dynamics, heat transfer, and solidification behaviour of a single molten droplet impinging on a solid surface of different inclinations', International Journal of Thermal Sciences, 224 (2026)

|

||||||||||

| 2026 |

Barustan MIA, Copland E, Nguyen TBT, Jenkins DR, O’dea D, Honeyands T, 'Reducibility of iron ore sinter analogues under hydrogen-enriched and conventional blast furnace gas compositions', ISIJ International (2026)

|

Open Research Newcastle | |||||||||

| 2026 |

Garlick C, Singh T, Paymooni K, O’Dea D, Honeyands T, 'Correction to: Electrode Smelting of Hydrogen-Reduced Hematite–Goethite at Laboratory Scale (Journal of Sustainable Metallurgy, (2025), 10.1007/s40831-025-01281-2)', Journal of Sustainable Metallurgy, 12 (2026)

|

||||||||||

| 2025 |

Rahmatmand B, Khoshk Rish S, Lomas H, North L, Honeyands T, Tahmasebi A, 'Reaction-diffusion Kinetics Modelling of Coke Gasification in Simulated H2 Reduction Blast Furnace', ISIJ International, 65, 756-768 (2025) [C1]

|

||||||||||

| 2025 |

Aladejebi OA, Mitra S, Singh T, Pinson DJ, Chew S, Honeyands T, 'Effect of Ultrafine Iron Ore Addition on Green Bed Properties and Sinter Productivity', ISIJ International, 65, 937-947 (2025) [C1]

|

||||||||||

| 2025 |

Aladejebi OA, Mitra S, Pinson DJ, Chew S, Honeyands T, 'Countermeasures to Improve Sinter Productivity', ISIJ International, 65, 2117-2128 (2025) [C1]

|

||||||||||

| 2025 |

Barustan MIA, Huang R, Copland E, Nguyen TBT, O’Dea D, Knackstedt M, Honeyands T, 'A Preliminary Study on Reduction Degradation of Iron Ore Sinter Using Sinter Analogue and X-ray Micro-computed Tomography (MCT)', ISIJ International, 65, 1754-1759 (2025) [C1]

|

||||||||||

| 2025 |

Moradmand S, Honeyands T, Allen J, 'Optimized electrolytic reduction of iron oxide and hematite ore in molten lithium carbonate', Journal of Cleaner Production, 530 (2025) [C1]

|

||||||||||

| 2025 |

Garlick C, Singh T, Paymooni K, O’Dea D, Honeyands T, 'Electrode Smelting of Hydrogen-Reduced Hematite–Goethite at Laboratory Scale', Journal of Sustainable Metallurgy (2025) [C1]

|

Open Research Newcastle | |||||||||

| 2025 |

Wang R, Cole MJ, Tremain P, Honeyands T, 'Impact of Reduction Conditions on Metallic Fe Growth Mechanism of Australian Ores in H2-Fluidized Bed', Journal of Sustainable Metallurgy (2025) [C1]

|

||||||||||

| 2025 |

Lu G, Khoshk Rish S, Lomas H, Honeyands T, Tahmasebi A, 'Ferro-coke 3D Microstructure Development and Impacts on Mechanical Strength', ISIJ International, 65, 2105-2116 (2025)

|

||||||||||

| 2025 |

Aladejebi OA, Mitra S, Singh T, Pinson DJ, Chew SJ, Honeyands T, 'A review of the sintering technologies to accommodate contemporary raw materials blends for ironmaking', Ironmaking and Steelmaking (2025) [C1]

|

Open Research Newcastle | |||||||||

| 2025 |

Chowdhury R, Evans G, Honeyands T, Monaghan BJ, Scimone D, Mitra S, 'A 2D Numerical Modeling Study of Slag Splashing in a Basic Oxygen Steelmaking Furnace', ACS Engineering Au, 5, 98-114 (2025) [C1]

|

||||||||||

| 2025 |

Longbottom RJ, Aladejebi OA, Jang KO, Nguyen TBT, Mitra S, Honeyands T, Zulli P, Cheng S, O’Dea D, Monaghan BJ, 'Effects of Slag Composition on Phosphorus Segregation to Dicalcium Silicate-Tricalcium Phosphate Solid Solution for Recycling of Basic Oxygen Steelmaking Slags', Journal of Sustainable Metallurgy, 11, 2485-2498 (2025) [C1]

|

||||||||||

| 2024 |

Chowdhury R, Hoque MM, Evans G, Honeyands T, Monaghan BJ, Scimone D, Mitra S, 'Impact dynamics and solidification behaviour of a molten droplet on a flat surface at different Weber numbers', EXPERIMENTAL THERMAL AND FLUID SCIENCE, 154 (2024) [C1]

|

||||||||||

| 2024 |

Mitra S, Hoque MM, O'Dea D, Honeyands T, 'Understanding cohesive zone behaviour of blast furnace based on computed tomography flow modelling in a fused bed of ferrous and coke particles', POWDER TECHNOLOGY, 439 (2024) [C1]

Performance of ironmaking blast furnace systems critically depends on the permeability of the cohesive zone which involves flow of reducing gas through a packed bed of ... [more] Performance of ironmaking blast furnace systems critically depends on the permeability of the cohesive zone which involves flow of reducing gas through a packed bed of fused ferrous and coke particles at high temperature. This study systematically investigated the effect of operating temperature on bed permeability for two different ferrous burdens - pellets, and pellets-sinter mixture supported on coke particles. To quantify the structural changes in the bed, interrupted tests at various temperatures were conducted and bed porosity was estimated using synchrotron X-ray computed tomography (CT) technique. Bed porosity showed decreasing trends with increasing temperature. A CT image based computational flow dynamics (CFD) model was developed which showed linearly decreasing trends of bed permeability parameter with increasing temperature indicating a significant loss of bed permeability in the high temperature cases. This behaviour was more pronounced for the pure pellet case compared to the mixed burden case.

|

Open Research Newcastle | |||||||||

| 2024 |

Barrett N, Mitra S, Copland E, Chew S, O'Dea D, Honeyands T, 'Changes in Microscale Liquid Formation in Lump and Sinter Mixed Burden Softening and Melting Tests with the Addition of Hydrogen', METALLURGICAL AND MATERIALS TRANSACTIONS B-PROCESS METALLURGY AND MATERIALS PROCESSING SCIENCE, 55, 1712-1734 (2024) [C1]

Abstract: With the movement toward hydrogen-enriched blast furnace operation to lower greenhouse gas emissions, ferrous burden design must be reconsidered to optimize f... [more] Abstract: With the movement toward hydrogen-enriched blast furnace operation to lower greenhouse gas emissions, ferrous burden design must be reconsidered to optimize furnace permeability. Increasing the ratio of direct charge lump ore in the ferrous burden also presents an opportunity to lessen the emissions associated with the production of sinter and pellets. Under traditional blast furnace conditions, lump ore usage is improved by mixing it with the sinter in the burden to promote their favorable high-temperature interactions (both chemical and physical). As such, mechanistic changes to the interaction must be understood to optimize burden design, including for future operations with hydrogen addition. In this study, liquid formation in both the metallic and oxide components of ferrous burdens is microscopically investigated. Oxide liquid and solid phase stability at the interfaces of dissimilar burdens are visualized using a novel mapping technique, and metallic iron is etched to reveal microstructures indicative of carbon. Results indicate that the inclusion of hydrogen promotes the gas carburization of metallic iron in sinter, but not lump. It was concluded that mixed burden softening and melting performance with hydrogen addition were improved through the addition of lump in two ways: the highly metallic lump particles provide structural support for the collapsing sinter bed and also suppress the formation of early liquid slag from the sinter. Graphical Abstract: (Figure presented.)

|

Open Research Newcastle | |||||||||

| 2024 |

Barustan MIA, Copland E, Nguyen TBT, O’Dea D, Honeyands T, 'Reduction Degradation of Lump, Sinter, and Pellets in Blast Furnace with Hydrogen Injection', ISIJ International, 64, 1517-1527 (2024) [C1]

The increase of hydrogen usage in a blast furnace is expected to affect the reduction degradation of ferrous burden materials and influence the gas permeability inside ... [more] The increase of hydrogen usage in a blast furnace is expected to affect the reduction degradation of ferrous burden materials and influence the gas permeability inside the furnace. Previous studies show a disagreement on the effect of H2 on reduction degradation, with the extent of degradation depending on the H2 content and type of ferrous burden materials. In this study, the reduction degradation of sinter, lump, and pellet was compared using the reduction degradation test under different gas mixtures containing CO and H2, covering the gas composition of conventional and H2 injection blast furnaces. Lump (Newman Blend Lump NBLL) and pellets show a lower RDI-2.8 than sinter under all the gas compositions tested. Higher RDI-2.8 values were obtained for all burden materials with a reducing gas containing both CO and H2 compared to CO or H2 only. The addition of H2 to CO increases the pore diffusion rate allowing reducing gas to reach the centre part of the particles, leading to the reduction of hematite to magnetite and subsequent crack formation across the whole particles. Compared to the conventional blast furnace case, NBLL lump and sinter show a lower degradation for the H2 injection case while it was the opposite for the pellet, suggesting the necessity of reviewing overall burden materials to optimise the hydrogen injection in the blast furnace.

|

Open Research Newcastle | |||||||||

| 2024 |

Nguyen TBT, Singh T, O'Dea D, Matthews L, Honeyands T, 'Experimental analysis of the melt fraction - mechanical strength relationship for iron ore sinter analogues', POWDER TECHNOLOGY, 439 (2024) [C1]

This study examined the strength of sinter analogue tablets for different types of iron ore under varying sintering conditions. A steel tamper was designed to quantify ... [more] This study examined the strength of sinter analogue tablets for different types of iron ore under varying sintering conditions. A steel tamper was designed to quantify strength based on the percentage of 1 mm retained size after a drop weight test. The study found a linear relationship between total melt fraction M and strength index S quantified by mass fraction of the +1 mm retained size: S=0.88M. Importantly, a relationship was found between the total melt and a combined F factor incorporating the thermodynamic liquid fraction (a, representing sintering conditions) and the mineralogical factor loss on ignition (LOI ratio, ß, representing ore types), where F=6.5a+ß-1. This factor F was found well correlated the total melt via an asymptotic exponential relationship as M=1-2.6e-F. The results also suggested that, to achieve an acceptable strength of 80% +1 mm for a typical basicity B = 2, a sintering temperature range between 1273 and 1370 °C is required for the LOI range between 1.6% to 10.7% respectively. Finally, an analogous analysis was also carried out which proposed a similar trend between sinter yield obtained in a kilogram-scale by lab-scale studies and the present 0.6-g analogue scale.

|

Open Research Newcastle | |||||||||

| 2024 |

Wang R, Purohit S, Paymooni K, Honeyands T, 'Sticking in Shaft Furnace and Fluidized Bed Ironmaking Processes: A Comprehensive Review Focusing on the Effect of Coating Materials', METALLURGICAL AND MATERIALS TRANSACTIONS B-PROCESS METALLURGY AND MATERIALS PROCESSING SCIENCE, 55, 2977-3006 (2024) [C1]

Production of direct reduced iron (DRI), particularly with green hydrogen, is a key pathway to the decarbonization of the iron and steel industry. However, the sticking... [more] Production of direct reduced iron (DRI), particularly with green hydrogen, is a key pathway to the decarbonization of the iron and steel industry. However, the sticking tendency during the production of DRI creates serious operational issues and limits production outputs. Coating inert materials on the surface of iron ores can act as a barrier to effectively prevent the bonding between newly formed iron surfaces, and can interfere with the formation of iron whiskers. However, the principle of coating has not been systematically studied. This review covers the mechanism of sticking in both shaft furnaces and fluidized bed-based gaseous DRI production. The factors that influence the reduction kinetics and morphology, including physical and chemical ore properties, pellet induration conditions, and reduction conditions are summarized as well. Understanding the relationship between these factors and morphology change is critical to eliminating the sticking issues of DRI. Findings from this study suggest that coating with inert additives (e.g., metal oxides) can successfully prevent sticking in both shaft furnaces and fluidized bed processes. The types of additives and coating methods, the stage of reduction where the coating is applied, and reduction temperature will dramatically affect the coating performance. The outlook is discussed as well given the need for further work to improve the performance of coating (methods, timing, and cheaper alternatives), to further de-risk DRI technologies.

|

||||||||||

| 2023 |

Barrett N, Mitra S, Doostmohammadi H, O'Dea D, Zulli P, Chew S, Honeyands T, 'Development of softening and melting testing conditions simulating blast furnace operation with hydrogen injection', IRONMAKING & STEELMAKING [C1]

|

Open Research Newcastle | |||||||||

| 2023 |

Barrett N, Mitra S, Chew S, O'Dea D, Honeyands T, 'Effect of Hydrogen Addition on Softening and Melting Performance of Lump and Sinter Mixed Burden', ISIJ INTERNATIONAL, 63, 1626-1636 (2023) [C1]

Hydrogen-enriched blast furnace (BF) operation is currently being assessed to mitigate greenhouse gas emissions while the steelmaking industry transitions to low carbon... [more] Hydrogen-enriched blast furnace (BF) operation is currently being assessed to mitigate greenhouse gas emissions while the steelmaking industry transitions to low carbon emission technologies. Increasing the usage of lump ore in the BF also presents opportunity to decrease carbon emissions, as it can be directly charged to the furnace without agglomeration. Use of lump ore in modern blast furnace operations is facilitated by high temperature interactions with sinter. With more emphasis on hydrogen enrichment in BF operations, the behaviour of lump and sinter mixed burdens must be characterised under new conditions. In this study, 15% hydrogen is added to the standard gas conditions of a Softening and Melting (S&M) apparatus (replacing nitrogen). Analysis of auxiliary reactions such as the Boudouard Reaction and the Water-Gas Shift Reaction is presented and their impact on burden reduction and performance assessed. Results indicate that with the inclusion of hydrogen, the performance of sinter burden deteriorates, while lump burden shows significant improvement. Interaction between sinter and lump still occurred with the inclusion of hydrogen in the gas, and the mixed burden behaviour of 20% lump and 80% sinter fell between that of the individual burdens. From interrupted experiments, it is noted at high degrees of reduction, the lump burden forms a solid metallic layer which maintains its interparticle voidage at high temperatures, supressing exudation of liquid slag.

|

Open Research Newcastle | |||||||||

| 2023 |

Rahmatmand B, Tahmasebi A, Lomas H, Honeyands T, Koshy P, Hockings K, Jayasekara A, 'A technical review on coke rate and quality in low-carbon blast furnace ironmaking', FUEL, 336 (2023) [C1]

The blast furnace technology is still the main ironmaking route with a current global share of 70%. Reduction of fossil carbon consumption and CO2 emissions in blast fu... [more] The blast furnace technology is still the main ironmaking route with a current global share of 70%. Reduction of fossil carbon consumption and CO2 emissions in blast furnace operations are essential for the decarbonization of steelmaking. Potential solutions such as introducing renewable carbon-based materials (torrefied biomass, charcoal), using hydrogen-enriched reducing gases (i.e., hydrogen gas, coke oven gas, reformed coke oven gas, green methane), oxygen enrichment with top gas recycling, and carbon capture and storage/utilization have been considered to decrease emissions. The enhanced sustainability of blast furnace operations depends primarily on improving the hydrogen-to-carbon replacement ratio. Hydrogen is an effective reducing agent, producing steam during the reduction of ferrous burden. The replacement of coke and PCI with hydrogen leads to reduced fuel rates and CO2 emissions. Although implementing the innovative ironmaking solutions reduces coke and coal consumption, coke cannot be replaced entirely as it plays an irreplaceable role as a mechanical support network and the permeable layer for gas movement in the blast furnace. The injection of alternative reducing agents into the blast furnace alters the reaction environment by changing gas composition and temperature. Therefore, understanding the impacts of new reaction conditions on coke rate and quality requirements is important to both coal producers and steel manufacturers. This paper reviews the current understanding of how the introduction of alternative reducing agents into the blast furnace influences the gasification behavior, degradation mechanism, and consumption rate of coke. The review also identifies the knowledge gaps and future research opportunities in the field.

|

Open Research Newcastle | |||||||||

| 2023 |

Tang K, Da Wang Y, Niu Y, Honeyands TA, O'Dea D, Mostaghimi P, Armstrong RT, Knackstedt M, 'Particle classification of iron ore sinter green bed mixtures by 3D X-ray microcomputed tomography and machine learning', POWDER TECHNOLOGY, 415 (2023) [C1]

The iron ore sintering process needs to be optimised to decrease its energy intensity and emissions of carbon and atmospheric pollutants, while continuing to produce si... [more] The iron ore sintering process needs to be optimised to decrease its energy intensity and emissions of carbon and atmospheric pollutants, while continuing to produce sinter of sufficient quality for current and future low carbon blast furnace operations. Ideally, the sinter structure and mineralogy should be related back to the particle-level structure of the iron ore types mixed from different mine sources. This particle-level detail can be visually obtained by 3D X-ray micro-Computed Tomography (micro-CT), but requires subsequent algorithms to individually identify and classify particles and identify the relationship between ore sources and sinter quality. In this study, individual particles in sinter green ¿ beds comprising a mixture of coking coal, fluxes, return fines and 5 iron ore samples from different mine sources are identified and classified in high resolution micro-CT images using a machine learning algorithm and associated data processing workflow. Coking coal, fluxes, and return fines are first segmented from iron ores based on their X-ray attenuation and texture. By imaging individual samples from each iron ore source, reliable training data is readily obtained from particle isolation with Convolutional Neural Networks (CNNs) guided by Trainable Weka Segmentation (TWS). Supervised machine learning is then applied to the datasets of isolated particles to produce a per-particle segmented digital sinter green bed image. A collection of geometric, texture, and greyscale features are computed for the particles and used to train a gradient boosting classifier. Tests are then performed on unseen subsets of the single ore source data, on a stratified mixture, and on a random mixture. An accuracy over 90% is achieved for iron ores that are morphologically domain-distinct in their feature space, while lower accuracy in the order of 40%¿80% is achieved between iron ore particles that derive from different mine sources, but are domain-similar, suggesting similar mineralogy. The effect of limited training domain, the visual/morphological/feature space similarities and the resulting domain shift in data between training and testing are carefully analysed to identify major sources of similarity. This per-particle multilabel classification of sinter green bed mixtures distinguishes both similar and distinct ores from different mines, and provides a high resolution, accurately characterised digital twin analogue of mixed iron ore sinter green beds. This allows for future detailed analysis of sinter quality, energy intensity, and carbon emissions during the metallurgical process, all of which could be optimised to produce cleaner, higher quality iron.

|

Open Research Newcastle | |||||||||

| 2022 |

Barrett N, Mitra S, Doostmohammadi H, O'Dea D, Zulli P, Chew S, Honeyands T, 'Assessment of Blast Furnace Operational Constraints in the Presence of Hydrogen Injection', ISIJ INTERNATIONAL, 62, 1168-1177 (2022) [C1]

|

Open Research Newcastle | |||||||||

| 2022 |

Honeyands T, Nguyen TBT, Pinson D, Connolly PRJ, Pownceby M, Manuel J, Matthews L, Leedham J, Singh T, O'Dea DP, 'Variation in Iron Ore Sinter Mineralogy with Changes in Basicity', MINERALS, 12 (2022) [C1]

|

Open Research Newcastle | |||||||||

| 2022 |

Singh T, Mitra S, O'dea D, Knuefing L, Honeyands T, 'Quantification of Resistance and Pressure Drop at High Temperature for Various Suction Pressures During Iron Ore Sintering', ISIJ INTERNATIONAL, 62, 1768-1776 (2022) [C1]

|

Open Research Newcastle | |||||||||

| 2022 |

Nguyen TBT, Mitra S, Evans GM, Doostmohammadi H, Monaghan BJ, Zulli P, Jang K-O, O'Dea D, Honeyands T, 'Segregation of a Phosphorus Rich Phase During Differential Solidification of BOF Slag', METALLURGICAL AND MATERIALS TRANSACTIONS B-PROCESS METALLURGY AND MATERIALS PROCESSING SCIENCE, 53, 3054-3070 (2022) [C1]

|

Open Research Newcastle | |||||||||

| 2021 |

Nguyen TBT, Mitra S, Evans G, Monaghan B, Zulli P, Jang K-O, O’Dea D, Honeyands T, 'Determining Drag Coefficient of Simplified Dendritic Particles in Metallurgical Systems', Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science (2021) [C1]

|

Open Research Newcastle | |||||||||

| 2021 |

Nguyen TBT, Mitra S, Evans G, Monaghan BJ, Zulli P, Jang K-O, O’Dea D, Honeyands T, 'Numerical Study into Gravity Separation of Phosphorus from BOS Slag during Solidification', ISIJ International, 61, 705-7114 (2021) [C1]

|

Open Research Newcastle | |||||||||

| 2021 |

Singh T, Li H, Zhang G, Mitra S, Evans G, O’dea D, Honeyands T, 'Iron Ore Sintering in Milli-Pot: Comparison to Pilot Scale and Identification of Maximum Resistance to Air Flow', ISIJ International, advpub (2021) [C1]

In the iron ore sintering process, the resistance to air flow is a major factor in deciding the flame front speed, which influences the sinter productivity and quality.... [more] In the iron ore sintering process, the resistance to air flow is a major factor in deciding the flame front speed, which influences the sinter productivity and quality. In this work, pressure drop during sintering and the resistance to air flow was investigated in milli-pot sintering for different coke rates. The sintering experiments were conducted in a milli-pot (diameter 53 mm, height 400 mm) and pressure and temperature were measured at the same locations in the bed by four taps located equidistant to each other. The yield of sinter product was measured following a modified drop test and the mineralogy of the sinter product was analysed. The results from milli-pot sintering were then compared to the reported results from standard pilot-scale sintering, and it was found that the lower half of the milli-pot bed gave a reasonable representation of the pilot-scale sintering process. The results of sinter mineralogy, yield and productivity of the lower half of milli-pot at 5.5-8.0% coke rate were found to be similar to pilot-scale sintering tests at a corresponding coke rate from 3.5 to 5.5%. The maximum resistance to air flow in the bed was found to be in the region between the leading edge of the flame front at ~100°C and the trailing edge of the flame front at ~1 200°C. This suggests that the maximum resistance to air flow includes the effect of de-humidification and combustion in addition to the high temperature "flame front" region usually defined at temperatures above 1 100°C or 1 200°C.

|

Open Research Newcastle | |||||||||

| 2021 |

Connor JO', Nguyen TBT, Honeyands T, Monaghan B, O'Dea D, Rinklebe J, Vinu A, Hoang SA, Singh G, Kirkham MB, Bolan N, 'Production, characterisation, utilisation, and beneficial soil application of steel slag: A review', JOURNAL OF HAZARDOUS MATERIALS, 419 (2021) [C1]

Slags are a co-product produced by the steel manufacturing industry and have mainly been utilised for aggregates in concreting and road construction. The increased util... [more] Slags are a co-product produced by the steel manufacturing industry and have mainly been utilised for aggregates in concreting and road construction. The increased utilisation of slag can increase economic growth and sustainability for future generations by creating a closed-loop system, circular economy within the metallurgical industries. Slags can be used as a soil amendment, and slag characteristics may reduce leachate potential of heavy metals, reduce greenhouse gas emissions, as well as contain essential nutrients required for agricultural use and environmental remediation. This review aims to examine various slag generation processes in steel plants, their physicochemical characteristics in relation to beneficial utilisation as a soil amendment, and environmental implications and risk assessment of their utilisation in agricultural soils. In relation to enhancing recycling of these resources, current and emerging techniques to separate iron and phosphorus slag compositions are also outlined in this review. Although there are no known immediate direct threats posed by slag on human health, the associated risks include potential heavy metal contamination, leachate contamination, and bioaccumulation of heavy metals in plants, thereby reaching the food chain. Further research in this area is required to assess the long-term effects of slag in agricultural soils on animal and human health.

|

Open Research Newcastle | |||||||||

| 2021 |

Donskoi E, Hapugoda S, Manuel JR, Poliakov A, Peterson MJ, Mali H, Bueckner B, Honeyands T, Pownceby MI, 'Automated Optical Image Analysis of Iron Ore Sinter', MINERALS, 11 (2021) [C1]

Sinter quality is a key element for stable blast furnace operation. Sinter strength and reducibility depend considerably on the mineral composition and associated textu... [more] Sinter quality is a key element for stable blast furnace operation. Sinter strength and reducibility depend considerably on the mineral composition and associated textural features. During sinter optical image analysis (OIA), it is important to distinguish different morphologies of the same mineral such as primary/secondary hematite, and types of silico-ferrite of calcium and aluminum (SFCA). Standard red, green and blue (RGB) thresholding cannot effectively segment such morphologies one from another. The Commonwealth Scientific Industrial Research Organization's (CSIRO) OIA software Mineral4/Recognition4 incorporates a unique textural identification module allowing various textures/morphologies of the same mineral to be discriminated. Together with other capabilities of the software, this feature was used for the examination of iron ore sinters where the ability to segment different types of hematite (primary versus secondary), different morphological sub-types of SFCA (platy and prismatic), and other common sinter phases such as magnetite, larnite, glass and remnant aluminosilicates is crucial for quantifying sinter petrology. Three different sinter samples were examined. Visual comparison showed very high correlation between manual and automated phase identification. The OIA results also gave high correlations with manual point counting, X-ray Diffraction (XRD) and X-ray Fluorescence (XRF) analysis results. Sinter textural classification performed by Recognition4 showed a high potential for deep understanding of sinter properties and the changes of such properties under different sintering conditions.

|

Open Research Newcastle | |||||||||

| 2021 |

Hoque MM, Doostmohammadi H, Mitra S, O'dea D, Liu X, Honeyands T, 'High Temperature Softening and Melting Interactions Between Newman Blend Lump and Sinter', ISIJ INTERNATIONAL, 61, 2944-2952 (2021) [C1]

|

Open Research Newcastle | |||||||||

| 2020 |

Harvey T, Honeyands T, O'Dea D, Evans G, 'Sinter Strength and Pore Structure Development using Analogue Tests', ISIJ International, 60, 73-83 (2020) [C1]

|

Open Research Newcastle | |||||||||

| 2020 |

Harvey T, Pownceby MI, Chen J, Webster NAS, Nguyen TBT, Matthews L, O'Dea D, Honeyands T, 'Effect of Temperature, Time, and Cooling Rate on the Mineralogy, Morphology, and Reducibility of Iron Ore Sinter Analogues', JOM, 73, 345-355 (2020) [C1]

Analogue sinter tablets were produced at temperatures between 1250°C and 1320°C, with a range of hold times and cooling rates. Platy silico-ferrite of calcium and alumi... [more] Analogue sinter tablets were produced at temperatures between 1250°C and 1320°C, with a range of hold times and cooling rates. Platy silico-ferrite of calcium and aluminum (SFCA) morphology was identified in samples produced at 1250°C using reflected light microscopy; however, quantitative x-ray diffraction (XRD) identified the presence of the SFCA phase, with no SFCA-I detected. This proves that the platy SFCA morphology common in analysis by reflected light microscopy cannot be attributed to the SFCA-I mineral without further analysis. Micro-XRD and electron probe micro-analysis (EPMA) were carried out on an area of platy SFCA confirming this result. The sinter analogue tablets were reduced in a 30% CO, 70% N2 gas mixture at 900°C in a tube furnace thermo-gravimetric analyzer. The degree of reduction of the tablets in this study was found to be controlled by the porosity of the samples, rather than by the morphology or mineralogy of the bonding phase.

|

Open Research Newcastle | |||||||||

| 2020 |

Mitra S, Liu X, Honeyands T, Evans G, O'Dea D, Zulli P, 'Pressure-drop Modelling in the Softening and Melting Test for Ferrous Burden', Iron and Steel Institute of Japan (ISIJ) International, 60, 1416-1426 (2020) [C1]

|

Open Research Newcastle | |||||||||

| 2019 |

Li C, Honeyands T, O'Dea D, Moreno-Atanasio R, 'DEM study on size segregation and voidage distribution in green bed formed on iron ore sinter strand', Powder Technology, 356, 778-789 (2019) [C1]

|

Open Research Newcastle | |||||||||

| 2019 |

Liu X, Honeyands T, Evans G, Zulli P, O'Dea D, 'A review of high-temperature experimental techniques used to investigate the cohesive zone of the ironmaking blast furnace', Ironmaking & Steelmaking, 46, 953-967 (2019) [C1]

|

Open Research Newcastle | |||||||||

| 2019 |

Honeyands T, Manuel J, Matthews L, O'Dea D, Pinson D, Leedham J, Zhang G, Li H, Monaghan B, Liu X, Donskoi E, Webster NAS, Pownceby MI, 'Comparison of the Mineralogy of Iron Ore Sinters Using a Range of Techniques', MINERALS, 9 (2019) [C1]

|

Open Research Newcastle | |||||||||

| 2019 |

Li C, Moreno-Atanasi R, O'Dea D, Honeyands T, 'Experimental Study on the Physical Properties of Iron Ore Granules Made from Australian Iron Ores', ISIJ INTERNATIONAL, 59, 253-262 (2019) [C1]

|

Open Research Newcastle | |||||||||

| 2019 |

Liu XL, Honeyands T, O’dea D, Mitra S, Chen J, Qiu GJ, 'Interaction between sinter and lump during softening and melting process', Kang T'ieh/Iron and Steel, 54, 19-26 (2019) [C1]

|

Open Research Newcastle | |||||||||

| 2018 |

Liu X, Honeyands T, Mitra S, Evans G, Godel B, George Acres R, Salvemini F, O'Dea D, Ellis B, 'A Novel Measurement of Voidage in Coke and Ferrous Layers in Softening and Melting under Load Test Using Synchrotron X-ray and Neutron Computed Tomography', ISIJ INTERNATIONAL, 58, 2150-2152 (2018) [C1]

|

Open Research Newcastle | |||||||||

| 2018 |

Harvey T, Honeyands T, Evans G, Godel B, O'Dea D, 'Analogue iron ore sinter tablet structure using high resolution X-ray computed tomography', Powder Technology, 339, 81-89 (2018) [C1]

|

Open Research Newcastle | |||||||||

| 2018 |

Zhou M, Zhou H, Honeyands T, O'dea DP, Ellis BG, Ma P, Yawei L, 'Evaluation of compressive strength and shear strength of the adhering layer of granules in iron ore sintering', Powder Technology, 338, 599-607 (2018) [C1]

|

Open Research Newcastle | |||||||||

| 2017 |

Li C, Honeyands T, O'Dea D, Moreno-Atanasio R, 'The angle of repose and size segregation of iron ore granules: DEM analysis and experimental investigation', Powder Technology, 320, 257-272 (2017) [C1]

|

Open Research Newcastle | |||||||||

| 2017 |

Zhou M, Zhou H, O'Dea DP, Ellis BG, Honeyands T, Gu X, 'Characterization of Granule Structure and Packed Bed Properties of Iron Ore Sinter Feeds that Contain Concentrate', ISIJ INTERNATIONAL, 57, 1004-1011 (2017) [C1]

Several sinter plants in China are still using significant proportions of local magnetite concentrate in the sinter blend based on supply proximity. However the overall... [more] Several sinter plants in China are still using significant proportions of local magnetite concentrate in the sinter blend based on supply proximity. However the overall trend is that concentrates are being replaced by more cost effective sinter fines. The fine size of concentrates results in additional challenges for sintering. In this study, granulation and packing experiments were conducted to investigate the influence of concentrate addition level on granule structure and green bed properties under a wide range of moisture and hydrated lime dosage levels. Provided sufficient water is added during granulation, the existence of micro-particles including concentrate and hydrated lime favours granule growth and increases the mass ratio of adhering layer to nuclei. However, at the same moisture and hydrated lime content, the introduction of more concentrate decreases the bed voidage remarkably since the thicker and weaker adhering layer deforms during dynamic packing. Compared to the 100% sinter fines base blend, introducing concentrate has a negative effect on bed permeability and therefore sinter productivity. For the 10% and 30% concentrate blends tested, increasing hydrated lime from 0 wt% to 4 wt% could improve the green bed permeability in JPU from 53.0 to 65.8 and 39.4 to 60.8 respectively. Based on the experimental results, a semi-empirical green bed voidage model was improved in two aspects. One is applying a one dimensional packing algorithm to get the ideal porosity of dry coarse particles utilising size distribution data rather than the simple log-normal deviation parameter. The other is to add a probability term considering the deformation of granules only happens to the adhering layer. Combined with the widely accepted population balance granulation model developed by Litster, the improved model can give more accurate predicted voidage values for modeling the sintering process and optimizing actual production from the properties of raw materials and moisture content.

|

Open Research Newcastle | |||||||||

| 2005 |

Caffer G, Rafiei P, Honeyands T, Trotter D, 'Understanding the melting characteristics of HBI in iron and steel melts', SEAISI Quarterly South East Asia Iron and Steel Institute, 34, 16-28 (2005)

An experimental and modelling program has been conducted by BHP Billiton to study the rate and mechanism of melting of hot briquetted iron (HBI) during steelmaking. Sin... [more] An experimental and modelling program has been conducted by BHP Billiton to study the rate and mechanism of melting of hot briquetted iron (HBI) during steelmaking. Single briquettes melt quickly relative to scrap, due to vigorous stirring from CO evolution caused by internal reaction of C and residual iron oxides. The melting rate is determined by the bath carbon level, with briquette carbon only important in a low carbon bath (< 0.1 wt%). This information can be used to optimise the HBI continuous feeding rate for steelmaking, or the batch addition profile. |

||||||||||

| 2000 |

Honeyands T, Truelove J, Trotter D, Brent A, Varcoe D, Seneviratne J, Sun S, 'Performance of HBI in scrap pre-heating systems', SEAISI Quarterly South East Asia Iron and Steel Institute, 29, 61-74 (2000)

The conditions necessary for the optimal use of Hot Briquetted Iron (HBI) in scrap pre-heating systems have been determined by experiment on a laboratory and pilot scal... [more] The conditions necessary for the optimal use of Hot Briquetted Iron (HBI) in scrap pre-heating systems have been determined by experiment on a laboratory and pilot scale. The development of a process model has allowed prediction of the pre-heat temperature that is achievable in shaft type systems, and the consequent electrical energy savings and productivity improvements possible for an electric arc furnace (EAF). The behaviour of HBI during pre-heating involves a complex series of chemical reactions, as shown in Figure 5. Single briquette experiments have demonstrated that gains in HBI metallisation can be realised during pre-heating. HBI was successfully heated to 1000°C in an atmosphere containing <5% oxygen in pilot scale studies (2 tonne batches). Metallisation gains of approximately 0.5 to 1% were measured for batches of FIOR/FINMET HBI, confirming the laboratory scale work. Models have been developed for an EAF and a generalised pre-heating system. The EAF model is a versatile heat and mass balance model for heating, melting and chemical reactions. Key operating parameters such as electrical energy, oxygen and flux consumption, off-gas temperature and composition canbe calculated. The off-gas conditions are used as an input to the pre-heater model, which calculates the gas and HBI temperature distributions and HBI metallisation along the pre-heat system. Model predictions for a shaft pre-heater suggest that a charge of scrap and HBI has a heat capture efficiency up to 25% higher than an all-scrap charge. Optimum conditions for pre-heating require the HBI to be in a layer near the bottom of the charge or uniformly dispersed with scrap throughout the charge. Continuous charging and discharge of the pre-heat shaft would improve the overall performance. The challenge that remains is to confirm the model predictions at full scale and to develop operating practices, such as the optimum layering strategy for a mixed charge. |

||||||||||

| 2000 |

McKay J, Archer R, Sahajwalla V, Young D, Honeyands T, 'Communications - Reoxidation of hot briquetted iron in salt water', METALLURGICAL AND MATERIALS TRANSACTIONS B-PROCESS METALLURGY AND MATERIALS PROCESSING SCIENCE, 31, 1133-1135 (2000)

Hot briquetting reduces the porosity and surfaces to volume ratio of direct reduced iron (DRI). The usual air oxidation of iron is slow at ambient temperatures and beco... [more] Hot briquetting reduces the porosity and surfaces to volume ratio of direct reduced iron (DRI). The usual air oxidation of iron is slow at ambient temperatures and becomes prominent only at temperatures above 500 °C. Briquettes passivated in air have a much slower corrosion rate in air at room temperature than unpassivated hot briquetted iron (HBI). Briquettes exhibit surface cracking, suggesting oxidation is not limited to the surface of the briquettes, but occurs also within the interior.

|

||||||||||

| 1999 |

Evans GM, Rigby GD, Honeyands TA, He QL, 'Gas dispersion through porous nozzles into down-flowing liquids', Chemical Engineering Science, 54, 4861-4868 (1999) [C1]

|

||||||||||

| Show 52 more journal articles | |||||||||||

Patent (1 outputs)

| Year | Citation | Altmetrics | Link |

|---|---|---|---|

| 2002 | Brent AD, Mayfield PJ, Crawford DP, Honeyands TA, Shook A, O'Dea D, 'Method for determining sticking and flow properties of particulate solids' (2002) |

Report (2 outputs)

| Year | Citation | Altmetrics | Link | ||

|---|---|---|---|---|---|

| 2022 |

Nguyen TBT, Honeyands T, O'Dea D, 'Sinter quality via sinter analogues: a review' (2022)

|

||||

| 2017 |

Guo J, Williams K, Chen W, Honeyands T, 'Moisture Measurement and Control for Iron Ore Conveyor Systems', 38-118 (2017)

|

Thesis / Dissertation (1 outputs)

| Year | Citation | Altmetrics | Link | ||

|---|---|---|---|---|---|

| 2023 |

Chowdhury R, 'SLAG SPLASHING DYNAMICS IN BASIC OXYGEN STEELMAKING FURNACE-A FUNDAMENTAL STUDY ON THE COATING FORMATION BY MOLTEN DROPLETS' (2023)

|

Open Research Newcastle |

Grants and Funding

Summary

| Number of grants | 29 |

|---|---|

| Total funding | $28,247,353 |

Click on a grant title below to expand the full details for that specific grant.

20252 grants / $1,222,956

Raw materials behaviour in low-emmision modified blast furnace$1,128,956

Funding body: Department of Education

| Funding body | Department of Education |

|---|---|

| Project Team | Assoc Prof Arash Tahmasebi, Assoc Prof Tom Honeyands |

| Scheme | Australian Trailblazer for Recycling and Clean Energy (ATRaCE) |

| Role | Investigator |

| Funding Start | 2025 |

| Funding Finish | 2026 |

| GNo | G2501242 |

| Type Of Funding | C1500 - Aust Competitive - Commonwealth Other |

| Category | 1500 |

| UON | Y |

Characterisation of Mixed Burden Softening and Melting Performance Under Sophisticated Hydrogen Enriched Laboratory Conditions$94,000

Funding body: Monash University

| Funding body | Monash University |

|---|---|

| Project Team | Dr Nathan Barrett, Assoc Prof Tom Honeyands, Dr Damien O'Dea |

| Scheme | Low Carbon Metallurgy Knowledge Centre - Funding Program |

| Role | Investigator |

| Funding Start | 2025 |

| Funding Finish | 2025 |

| GNo | G2401529 |

| Type Of Funding | C1700 - Aust Competitive - Other |

| Category | 1700 |

| UON | Y |

20242 grants / $2,978,306

University of Newcastle, Electric Smelting of Australian Hematite-Goethite DRI$2,938,049

Funding body: Australian Renewable Energy Agency (ARENA)

| Funding body | Australian Renewable Energy Agency (ARENA) |

|---|---|

| Project Team | Assoc Prof Tom Honeyands, Mr Craig Garlick, Dr Khadijeh Paymooni, Dr Damien O'Dea, Prof Johannes Schenk, Professor Johannes Schenk, Dr Thomas Echterhof |

| Scheme | Transformative Research Accelerating Commercialisation (TRAC) Program |

| Role | Lead |

| Funding Start | 2024 |

| Funding Finish | 2029 |

| GNo | G2300835 |

| Type Of Funding | C1500 - Aust Competitive - Commonwealth Other |

| Category | 1500 |

| UON | Y |

Physical and chemical properties of Australia ores associated with new processing technologies$40,257

Funding body: HILT CRC Limited

| Funding body | HILT CRC Limited |

|---|---|

| Project Team | Assoc Prof Tom Honeyands, Dr Subhasish Mitra |

| Scheme | Research Grant |

| Role | Lead |

| Funding Start | 2024 |

| Funding Finish | 2026 |

| GNo | G2401368 |

| Type Of Funding | CRC - Cooperative Research Centre |

| Category | 4CRC |

| UON | Y |

20232 grants / $984,222

Prevention of Sticking in H2 fluidised bed DRI production$964,122

Funding body: HILT CRC Limited

| Funding body | HILT CRC Limited |

|---|---|

| Project Team | Assoc Prof Tom Honeyands, Assoc Prof Tom Honeyands, Laur Prof Behdad Moghtaderi, Prof Kenneth Williams, Doctor John Pye, Professor Geoffrey Brooks, Brian McDonald, Chris McMahen, Dian Olwagen |

| Scheme | Research Grant |

| Role | Lead |

| Funding Start | 2023 |

| Funding Finish | 2026 |

| GNo | G2301168 |

| Type Of Funding | CRC - Cooperative Research Centre |

| Category | 4CRC |

| UON | Y |

Systematic analysis of processes and prospects of iron and steel metallurgy, being the Project described in the Project Plan.$20,100

Funding body: Australian Academy of Science

| Funding body | Australian Academy of Science |

|---|---|

| Project Team | Assoc Prof Tom Honeyands, Dr Evan Copland, Dr Oleksii Merkulov, Assoc Prof Arash Tahmasebi |

| Scheme | The Ukraine-Australia Research Fund: Short-term visits |

| Role | Lead |

| Funding Start | 2023 |

| Funding Finish | 2023 |

| GNo | G2300839 |

| Type Of Funding | C3200 – Aust Not-for Profit |

| Category | 3200 |

| UON | Y |

20228 grants / $1,752,557

Differential solidification of steel slag to create a fertiliser co-product$582,287

Funding body: BHP Billiton Innovation Pty Ltd

| Funding body | BHP Billiton Innovation Pty Ltd |

|---|---|

| Project Team | Assoc Prof Tom Honeyands, Prof Geoffrey Evans, Dr Tuyen Nguyen, Dr Subhasish Mitra, Associate Professor Brian Monaghan, Prof Nanthi Bolan, Dr Damien O'Dea, Professor Nanthi Bolan |

| Scheme | Linkage Projects Partner Funding |

| Role | Lead |

| Funding Start | 2022 |

| Funding Finish | 2024 |

| GNo | G2201032 |

| Type Of Funding | C3100 – Aust For Profit |

| Category | 3100 |

| UON | Y |

Differential solidification of steel slag to create a fertiliser co-product$525,483

Funding body: ARC (Australian Research Council)

| Funding body | ARC (Australian Research Council) |

|---|---|

| Project Team | Assoc Prof Tom Honeyands, Prof Geoffrey Evans, Dr Tuyen Nguyen, Dr Subhasish Mitra, Associate Professor Brian Monaghan, Prof Nanthi Bolan, Dr Damien O'Dea, Professor Nanthi Bolan |

| Scheme | Linkage Projects |

| Role | Lead |

| Funding Start | 2022 |

| Funding Finish | 2025 |

| GNo | G2101131 |

| Type Of Funding | C1200 - Aust Competitive - ARC |

| Category | 1200 |

| UON | Y |

Coke Reactivity with CO2 and H20 and Impacts on Coke Microstructure and Gas Diffusion$170,700

Funding body: Australian Coal Research Limited

| Funding body | Australian Coal Research Limited |

|---|---|

| Project Team | Assoc Prof Arash Tahmasebi, Assoc Prof Tom Honeyands, Assoc Prof David Jenkins, Assoc Prof Merrick Mahoney, Dr Subhasish Mitra |

| Scheme | Australian Coal Association Research Program (ACARP) |

| Role | Investigator |

| Funding Start | 2022 |

| Funding Finish | 2023 |

| GNo | G2101451 |

| Type Of Funding | C1700 - Aust Competitive - Other |

| Category | 1700 |

| UON | Y |

Hydrogen DRI Production$150,000

Funding body: BHP Billiton Marketing Asia

| Funding body | BHP Billiton Marketing Asia |

|---|---|

| Project Team | Assoc Prof Tom Honeyands, Mr Craig Garlick, Laur Prof Behdad Moghtaderi, Dr Khadijeh Paymooni |

| Scheme | Research Grant |

| Role | Lead |

| Funding Start | 2022 |

| Funding Finish | 2023 |

| GNo | G2200919 |

| Type Of Funding | C3400 – International For Profit |

| Category | 3400 |

| UON | Y |

Understanding and eliminating adverse materials behaviour during and after direct reduction in shaft and fluidised bed processes$144,187

Funding body: HILT CRC Limited

| Funding body | HILT CRC Limited |

|---|---|

| Project Team | Assoc Prof Tom Honeyands, Laur Prof Behdad Moghtaderi, Dr Mark Pownceby, Dr Suneeti Purohit |

| Scheme | Research Grant |

| Role | Lead |

| Funding Start | 2022 |

| Funding Finish | 2023 |

| GNo | G2200692 |

| Type Of Funding | CRC - Cooperative Research Centre |

| Category | 4CRC |

| UON | Y |

ACARP Support for International Symposium on Sustainable Cokemaking and Ironmaking$80,300

Funding body: Australian Coal Research Limited

| Funding body | Australian Coal Research Limited |

|---|---|

| Project Team | Assoc Prof Arash Tahmasebi, Doctor Hamid Doostmohammadi, Assoc Prof Tom Honeyands, Doctor Apsara Jayasekara, Mr Salman Khoshk Rish, Dr Soonho Lee |

| Scheme | Australian Coal Association Research Program (ACARP) |

| Role | Investigator |

| Funding Start | 2022 |

| Funding Finish | 2025 |

| GNo | G2200665 |

| Type Of Funding | Scheme excluded from IGS |

| Category | EXCL |

| UON | Y |

Gasification Kinetics of Coke Lumps Under Simulated Conventional and Hydrogen Rich Blast Furnace Processes$69,600

Funding body: Australian Coal Research Limited

| Funding body | Australian Coal Research Limited |

|---|---|

| Project Team | Assoc Prof Arash Tahmasebi, Assoc Prof Tom Honeyands, Doctor Apsara Jayasekara, Dr Hannah Lomas, Assoc Prof Merrick Mahoney |

| Scheme | Australian Coal Association Research Program (ACARP) |

| Role | Investigator |

| Funding Start | 2022 |

| Funding Finish | 2023 |

| GNo | G2101460 |

| Type Of Funding | C1700 - Aust Competitive - Other |

| Category | 1700 |

| UON | Y |

Abrasive Wear Performance of Grinding Balls Phase 2$30,000

Funding body: Moly-Cop USA LLC

| Funding body | Moly-Cop USA LLC |

|---|---|

| Project Team | Dr Dusan Ilic, Assoc Prof Tom Honeyands, Dr Aleksej Lavrinec, Prof Kenneth Williams |

| Scheme | Research Grant |

| Role | Investigator |

| Funding Start | 2022 |

| Funding Finish | 2022 |

| GNo | G2200746 |

| Type Of Funding | C3400 – International For Profit |

| Category | 3400 |

| UON | Y |

20212 grants / $55,625

Interaction of ferrous burden materials in the cohesive zone of the ironmaking blast furnace under hydrogen operation$30,000

Funding body: The Australasian Institute of Mining and Metallurgy (AusIMM)

| Funding body | The Australasian Institute of Mining and Metallurgy (AusIMM) |

|---|---|

| Project Team | Assoc Prof Tom Honeyands, Mr Nathan Barrett |

| Scheme | Education Endowment Fund |

| Role | Lead |

| Funding Start | 2021 |

| Funding Finish | 2023 |

| GNo | G2100669 |

| Type Of Funding | C3200 – Aust Not-for Profit |

| Category | 3200 |

| UON | Y |

Abrasive Wear Performance of Grinding Balls Phase 1$25,625

Funding body: Moly-Cop USA LLC

| Funding body | Moly-Cop USA LLC |

|---|---|

| Project Team | Dr Dusan Ilic, Assoc Prof Tom Honeyands, Prof Kenneth Williams |

| Scheme | Research Grant |

| Role | Investigator |

| Funding Start | 2021 |

| Funding Finish | 2022 |

| GNo | G2101144 |

| Type Of Funding | C3400 – International For Profit |

| Category | 3400 |

| UON | Y |

20202 grants / $10,397,052

BHP Centre for Ironmaking Materials Research$10,000,000

Funding body: BHP Billiton Innovation Pty Ltd

| Funding body | BHP Billiton Innovation Pty Ltd |

|---|---|

| Scheme | Research Grant |

| Role | Lead |

| Funding Start | 2020 |

| Funding Finish | 2024 |

| GNo | |

| Type Of Funding | C3111 - Aust For profit |

| Category | 3111 |

| UON | N |

ARC Research Hub for Australian Steel Innovation$397,052

Funding body: BHP Billiton Innovation Pty Ltd

| Funding body | BHP Billiton Innovation Pty Ltd |

|---|---|

| Project Team | Prof Geoffrey Evans, Dr Peter Austin, Prof Geoffrey Evans, Assoc Prof Tom Honeyands, Dr Soonho Lee, Associate Professor John Lucas, Mr Mathew Mcnamara, Dr Subhasish Mitra, Mr David Pinson, Epma Putri, Assoc Prof Arash Tahmasebi, Professor Jianglong Yu |

| Scheme | Industrial Transformation Research Hubs Partner Funding |

| Role | Investigator |

| Funding Start | 2020 |

| Funding Finish | 2024 |

| GNo | G2000874 |

| Type Of Funding | C3100 – Aust For Profit |

| Category | 3100 |

| UON | Y |

20183 grants / $226,462

Phosphorous and Iron recovery from Steelmaking Slag for Effective Recycling$90,000

Funding body: ARC (Australian Research Council)

| Funding body | ARC (Australian Research Council) |

|---|---|

| Project Team | Assoc Prof Tom Honeyands, Prof Geoffrey Evans |

| Scheme | Linkage Projects |

| Role | Lead |

| Funding Start | 2018 |

| Funding Finish | 2020 |

| GNo | G1701358 |

| Type Of Funding | C1200 - Aust Competitive - ARC |

| Category | 1200 |

| UON | Y |

Jord Multi Heart Research$80,000

Funding body: Jord International Pty Limited

| Funding body | Jord International Pty Limited |

|---|---|

| Project Team | Dr Jessica Allen, Assoc Prof Tom Honeyands, Dr Jie Guo |

| Scheme | Advanced METS Doctoral Training Centre Industry Scheme |

| Role | Investigator |

| Funding Start | 2018 |

| Funding Finish | 2021 |

| GNo | G1801136 |

| Type Of Funding | C3100 – Aust For Profit |

| Category | 3100 |

| UON | Y |

Phosphorous and Iron recovery from Steelmaking Slag for Effective Recycling$56,462

Funding body: BHP Billiton Innovation Pty Ltd

| Funding body | BHP Billiton Innovation Pty Ltd |

|---|---|

| Project Team | Assoc Prof Tom Honeyands, Prof Geoffrey Evans |

| Scheme | Linkage Projects Partner Funding |

| Role | Lead |

| Funding Start | 2018 |

| Funding Finish | 2020 |

| GNo | G1701360 |

| Type Of Funding | C3100 – Aust For Profit |

| Category | 3100 |

| UON | Y |

20171 grants / $1,835,776

ACARP Project C27001 - Maritime Regulation Project for Coal Self Heating Research and Assessment$1,835,776

Funding body: Australian Coal Research Limited

| Funding body | Australian Coal Research Limited |

|---|---|

| Project Team | Prof Kenneth Williams, Assoc Prof Merrick Mahoney, Assoc Prof Tom Honeyands, Professor Jianglong Yu, Dr Peter Robinson, Dr Jie Guo, Doctor Wei Chen, Dr Dusan Ilic |

| Scheme | Australian Coal Association Research Program (ACARP) |

| Role | Investigator |

| Funding Start | 2017 |

| Funding Finish | 2023 |

| GNo | G1700798 |

| Type Of Funding | C1700 - Aust Competitive - Other |

| Category | 1700 |

| UON | Y |

20161 grants / $194,800

Assessment of self-heating test standards and their applicability for determining self-heating susceptibility within coal storage and transport systems$194,800

Funding body: Australian Coal Research Limited

| Funding body | Australian Coal Research Limited |

|---|---|

| Project Team | Prof Kenneth Williams, Assoc Prof Tom Honeyands, Assoc Prof Merrick Mahoney, Professor Jianglong Yu, Professor Richard Bush, Dr Peter Robinson, Mr TOBIAS Krull |

| Scheme | Australian Coal Association Research Program (ACARP) |

| Role | Investigator |

| Funding Start | 2016 |

| Funding Finish | 2016 |

| GNo | G1601225 |

| Type Of Funding | Aust Competitive - Non Commonwealth |

| Category | 1NS |

| UON | Y |

20151 grants / $414,000

Moisture measurement and control for iron ore conveyor systems$414,000

Funding body: AMIRA International Limited

| Funding body | AMIRA International Limited |

|---|---|

| Scheme | Research Project |

| Role | Lead |

| Funding Start | 2015 |

| Funding Finish | 2017 |

| GNo | |

| Type Of Funding | External |

| Category | EXTE |

| UON | N |

20133 grants / $5,947,097

ARC Research Hub for Advanced Technologies for Australian Iron Ore$3,447,097

Funding body: ARC (Australian Research Council)

| Funding body | ARC (Australian Research Council) |

|---|---|

| Project Team | Assoc Prof Tom Honeyands, Emeritus Professor Alan Roberts, Prof Geoffrey Evans, Dr Benjamin Ellis, Mr Gregory Elphick, Mr Taavi Orupold, Mrs Lisa Allen, Prof Kenneth Williams, Dr Damien O'Dea, Laur Prof Kevin Galvin |

| Scheme | Industrial Transformation Research Hubs |

| Role | Lead |

| Funding Start | 2013 |