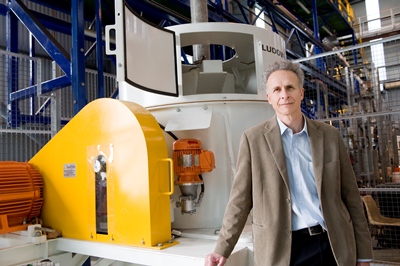

Laureate Professor Kevin Galvin

Distinguished Laureate Professor

School of Engineering (Chemical Engineering)

- Email:kevin.galvin@newcastle.edu.au

- Phone:0240339077

Turning the tide on mineral extraction

Professor Kevin Galvin's Reflux Classifier may sound like a creation akin to time-travel machines in fantasy films. In reality, it can save the global mining and minerals processing industry billions of dollars.

Video courtesy of Hase Media, ATSE Clunies Ross Awards 2014

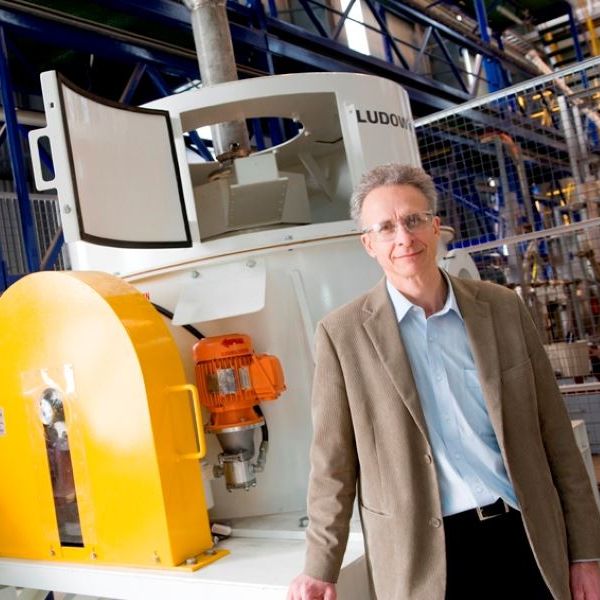

The award-winning technology, developed in collaboration with commercial partner Ludowici, and now with FLSmidth, is an industrial machine that separates fine particles on the basis of either density or size, improving the efficiency of the process with its unique tilted design.

For Professor Galvin, who is Director of the University of Newcastle's Centre for Critical Minerals and Urban Mining, and the ARC Industrial Transformation Research Hub for Advanced Technologies for Australian Iron Ore, it confirms his reputation as an internationally acclaimed chemical engineer.

The Reflux Classifier was developed by combing a conventional fluidized bed with a system of inclined channels to achieve enhanced rates of segregation of high density particles, and enhanced conveying of low density particles.

"The technique relies on the fact that the value of a material is usually related directly to its density," Professor Galvin said.

The Reflux Classifier can be applied to a relatively broad range of particle sizes, and achieve higher recovery of valuable material than other water-based technologies. The technology has succeeded in solving an existing processing problem by achieving the sharp separations essential in the recovery of premium, high grade metallurgical coal.

Professor Galvin received the Australian Academy of Science’s Sir Ian Wark Medal and Lecture in 2012, the Australian Academy of Technological Science and Engineering’s Clunies Ross Award in 2014, and the Australasian Institute of Mining and Metallurgy’s Mineral Industry Technique Award in 2014 in recognition of the underpinning research and industrial impact of the Reflux Classifier.

Under patent, over 100 Reflux Classifiers have been sold into more than ten countries with installed capacity estimated to be about 50 million tonnes per annum. Professor Galvin's research team, which forms part of the University's Newcastle Institute for Energy and Resources (NIER), continues to investigate the full potential of the concept in other areas.

"The technology has potential significance for any industry where a separation process based on particle size or density is applicable," Professor Galvin said.

"The chromate industry has recently installed a Reflux Classifier which is an important milestone for the commercialisation of the technology in the area of dense minerals."

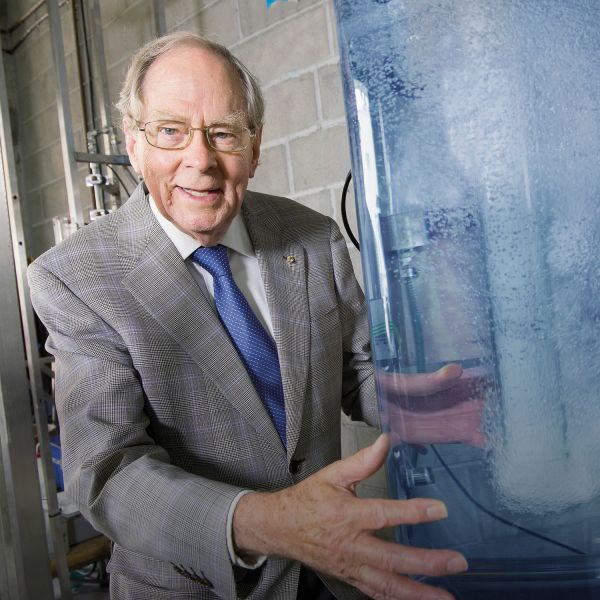

Dr Alan Broadfoot, Director of the Newcastle Institute for Energy and Resources (NIER), anticipates further success from Professor Galvin and his team.

“The development of the Reflux Classifier has created a pathway to impact for several new technologies at various stages of development which will soon be ready for commercialisation”, Dr Broadfoot said.

“Its not just about the science, but also the collaboration with the industry”.

The opening of NIER in mid-2011 further enhanced the strong collaboration between the University's engineering experts and industry.

The most comprehensive energy research institute of its kind in Australia, NIER confirms the Hunter region's reputation as a national hub for energy and resources research. The facility comprises extensive laboratories and industrial-scale pilot plant workshops unmatched by any Australian university.

Find out more

- Visit the Centre for Critical Minerals and Urban Mining website

- Visit the Newcastle Institute for Energy and Resources (NIER) website

- For more on industry investment opportunities visit the Newcastle Innovation website

Turning the tide on mineral extraction

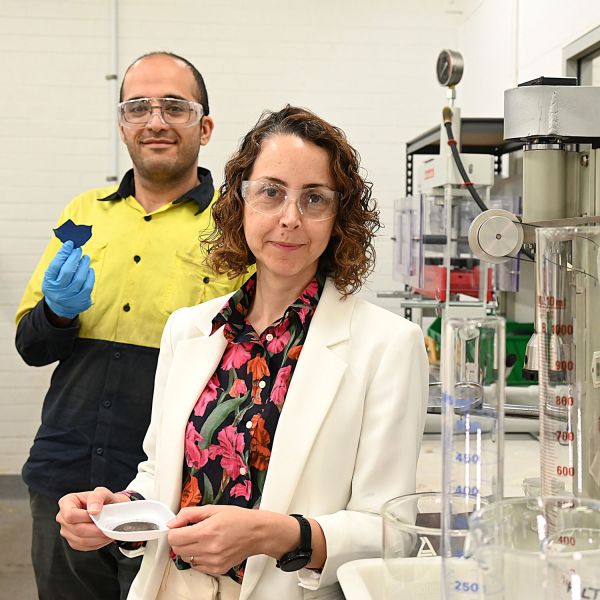

The Centre find solutions to problems in the mineral industry to maximise the separation of products from waste material, reduce water and energy usage

Career Summary

Biography

Laureate Professor Kevin Galvin joined the University of Newcastle in 1993. He is presently the Director of the ARC Centre of Excellence for Enabling Eco-Efficient Beneficiation of Minerals. Previously he spent 10 years with BHP Research (1980-1987; 1990-1993), and 3 years at Imperial College on a Commonwealth Scholarship where he did his PhD under the supervision of Professor Brian Briscoe. His primary research interests are in the phenomena of bubbles, drops and particles in the context of process systems. He invented a new separator termed the Reflux Classifier, developing the technology through an R&D Agreement with Ludowici Australia, and later FLSmidth. Following a research breakthrough in 2008 the technology was re-designed in 2009 to promote the effects of a laminar shear mechanism, leading to rapid acceptance and up-take by industry. The technology attracted a number of national and international awards and led to $B exports and over 180 installations in more than a dozen countries.

Research Expertise

I have built an active research group covering the generic theme of "bubbles, drops, and particles in process systems". My interest has been in the areas of surface chemistry, and the suspension mechanics of bubbles, drops, and particles. The bulk of this research has been directly relevant to mineral processing and more generally particle technology. I have a strong international reputation for my research in the area of mineral processing. I have worked extensively on interfacial problems concerned with surfactant adsorption onto bubbles in ion flotation and drops in emulsification. I have also worked on problems concerned with the nucleation of bubbles, drops, and solid particles, as well as problems concerned with their growth and coalescence. I have studied mass transfer, especially the molecular diffusion of molecules to growing bubbles, and the transport of gas molecules through interfaces containing adsorbed surfactants. Applied research in this area has led to the development of a new method for producing emulsion explosives.

My major research activity, however, has focused on the problem of separating particles on the basis of size and density in fluidized beds, and on the motion of particles near inclined surfaces. Fundamental studies, relevant to the emerging field of micro-fluidics were concerned with the role of surface roughness in these interactions, with a new understanding of how such phenomena might contribute to remarkably high levels of hydrodynamic diffusion. Other significant advances have been made in understanding dispersion in fluidized beds. The work on fluidized beds and inclined sedimentation has culminated in the development of the Reflux Classifier, a high throughput fluidized bed technology that has since been adopted by industry in many countries. Fundamental studies of this system have focused on the separation and transport of the particles through the inclined channels, with investigations of the particle lift force and other mechanisms of particle resuspension. We have also recently completed the first full-scale trial of a related technology, the Reflux Flotation Cell. This device increases the hydrodynamic capacity of flotation by an order of magnitude, delivering extreme levels of cleaning to the concentrate.

In more recent years my group has developed a novel technology that has the potential to change the way fine hydrophobic particles are recovered in industry. We have developed a novel binder that is effective in selectively agglomerating particles from less than a micron to several hundred microns within a few seconds, and arguably just a fraction of a second. The novel binder reduces the oil consumption of traditional agglomeration by more than an order of magnitude, via the establishment of very thin films of order 100 nm.

Qualifications

- PhD, University of London

- Bachelor of Engineering (Honours), University of Newcastle

- Diploma Imperial College (Chemical Engineering), Imperial College of Science Tech&Medicine-UK

Keywords

- Fluidization

- Gravity Separation

- Interfacial Phenomena

- Multiphase processes

- Nucleation

- Sedimentation

- Separation Processes

- Thermodynamics

Fields of Research

| Code | Description | Percentage |

|---|---|---|

| 401904 | Mineral processing/beneficiation | 100 |

Professional Experience

UON Appointment

| Title | Organisation / Department |

|---|---|

| Distinguished Laureate Professor | University of Newcastle School of Engineering Australia |

Academic appointment

| Dates | Title | Organisation / Department |

|---|---|---|

| Editorial Board | Coal Preparation - A Multinational Journal Australia |

|

| Editorial Board - Minerals Engineering | Minerals Engineering Australia |

|

| Fellow - Institution of Engineers Australia | Institution of Engineers Australia (IEAust) Australia |

|

| 1/1/2013 - 31/12/2015 | Expert - ARC College of Experts | ARC (Australian Research Council) |

| 1/1/2010 - 1/12/2010 | ERA Engineering Panel | ARC (Australian Research Council) |

Awards

Distinction

| Year | Award |

|---|---|

| 2015 |

Awarded University of Newcastle Alumni Medal for Professional Excellence The University of Newcastle |

| 2014 |

2014 Selected by Engineers Australia in Australia’s Top 100 Most Influential Engineers Institution of Engineers Australia (IEAust) |

Prize

| Year | Award |

|---|---|

| 2016 |

NSW Premier’s Prizes for Science and Engineering 2016, Energy Innovations in NSW Office of the NSW Chief Scientist and Engineer |

Recognition

| Year | Award |

|---|---|

| 2020 |

Fellow of Australian Academy of Science Australian Academy of Science |

| 2012 |

Fellow of Australian Academy of Technological Sciences and Engineering ATSE (Australian Academy of Technological Sciences and Engineering) |

Research Award

| Year | Award |

|---|---|

| 2018 |

Gaudin Award in Minerals Beneficiation, Society for Mining, Metallurgy and Exploration, for advancements in the science and engineering of innovative systems for coal and mineral beneficiation in 2017 Society for Mining, Metallurgy and Exploration |

| 2014 |

Clunies Ross ATSE (Australian Academy of Technological Sciences and Engineering) |

| 2014 |

Mineral Industry Technique Award Australasian Institute of Mining and Metallurgy |

| 2013 |

Pace Zenith Award Process & Control Engineering Magazine (PACE) |

| 2012 |

Ian Wark Medal and Lecture Australian Academy of Science |

| 2010 |

Core Chemical Engineering - International Innovation Award Institution of Chemical Engineers (IChemE) |

| 2006 |

Rio Tinto Award of Excellence in Chemical Engineering Institution of Engineers Australia (IEAust) |

| 2005 |

Best Research and Development Collaboration Business Higher Education Round Table |

| 2004 |

ACARP Research Excellence Award ACARP (Australian Coal Industry’s Research Program) |

Invitations

Keynote Speaker

| Year | Title / Rationale |

|---|---|

| 2018 |

Galvin, K.P., Innovation through Invention: Shifting the Paradigms of Mineral Processing, MPD Awards Plenary, SME Meeting, 26th February, Minneapolis, USA, 2018

|

| 2017 |

Galvin, K.P., “Challenges in Mineral Processing and Opportunities for the Industry”, AIMEX, 29th-31st August, Sydney Showground, 2017

|

| 2016 |

Plenary Session, Clearwater Clean Coal Conference, Panel Advanced Beneficiation, Key Note Presentation, K.P. Galvin, Ultrafast Beneficiation of Coal Tailings-New Fuel Options, Clearwater, June 7th 2016

|

| 2015 |

Galvin, K.P., Australian Research Council Research Hub for Advanced Technologies for Australian Iron Ore – An Introduction, Iron Ore 2015, Perth, AusIMM, 13th-15th July 2015

|

| 2014 |

Gravity Separation and Flotation of Fine Particles using the Reflux Classifier Platform Organisation: International Mineral Processing Congress Description: Major International Conference on Mineral Processing |

| 2011 |

Application of the Reflux Classifier for Measuring Gravity Recoverable Product Organisation: Society for Mining, Metallurgy, and Exploration SME Description: R-H Yoon Symposium, Annual SME Meeting, Denver USA |

| 2009 |

Physical Separation-Still Much More to Achieve through Innovation, Minerals Engineering, UK Organisation: Minerals Engineering Description: Physical Separation |

Speaker

| Year | Title / Rationale |

|---|---|

| 2012 |

Symposium on Challenges in Fine Coal Processing, Dewatering and Disposal Organisation: CPA SME Description: Development of the RefluxClassifier |

| 2003 |

Fundamentals of Liquid Fluidized Beds, SME Conference, USA Organisation: SME Meeting, Cincinatti Description: Fundamentals of Liquid Fluidized Beds |

Publications

For publications that are currently unpublished or in-press, details are shown in italics.

Book (1 outputs)

| Year | Citation | Altmetrics | Link | ||

|---|---|---|---|---|---|

| 2013 |

Osborne D, 'The coal handbook' (2013)

|

Chapter (9 outputs)

| Year | Citation | Altmetrics | Link | |||||

|---|---|---|---|---|---|---|---|---|

| 2023 |

Woodruff D, Verboomen J, Galvin KP, Iveson SM, 'Cleaning of coarse and small coal (250 mm×0.5 mm)', 1, 419-446 (2023)

Methods for cleaning larger than 0.5mm in size, which are defined as coarse and small coal, and their development are discussed. These processes are, in effect, the his... [more] Methods for cleaning larger than 0.5mm in size, which are defined as coarse and small coal, and their development are discussed. These processes are, in effect, the history of all coal processing from the 19th century onwards. The processes all use the difference in specific gravity of the various mineral constituents of Run of Mine coal. The technologies include water-based technologies such as Jigs, dense medium bath systems for large coal, 250mm×6mm and smaller coal, 50mm×0.5mm. Dry separation systems include air jigs, air-fluidized beds, air tables, and optical/X-Ray sorting. The preparation of coal plus 0.5mm accounts for approximately 85% of all coal processed globally.

|

|||||||

| 2023 |

Woodruff D, Verboomen J, Galvin KP, Iveson SM, '12 Cleaning of coarse and small coal (250mm×0.5mm)', 419-446 (2023)

|

|||||||

| 2013 |

Galvin KP, Iveson SM, 'Cleaning of coarse and small coal', The Coal Handbook: Towards Cleaner Production, Elsevier 263-300 (2013)

|

|||||||

| 2013 |

Galvin KP, Iveson SM, 'Cleaning of Coarse and Small Coal', 1, 263-300 (2013) [B1]

Methods for cleaning coal particles greater than 1.0. mm in size are discussed. Water-based technologies include jigs, dense (heavy) medium baths and cyclones, fluidise... [more] Methods for cleaning coal particles greater than 1.0. mm in size are discussed. Water-based technologies include jigs, dense (heavy) medium baths and cyclones, fluidised beds and Reflux Classifiers (RC). Dry-based methods include air jigs, air-fluidised beds and tables and optical/X-ray sorting. Likely future trends in plant design are discussed. Continued improvement in dry-based methods may see them being used more often as a preliminary de-stoning step for coarse particles. Improved water-based technologies will enable an increase in the upper size of the fine coal circuit, from 1. mm up to say 4. mm, which should significantly increase plant capacity.

|

Open Research Newcastle | ||||||

| 2012 | Galvin KP, 'Development of the reflux classifier', -, 159-185 (2012) [B1] | Open Research Newcastle | ||||||

| 2003 | Galvin KP, 'On the Phenomena of Hindered Settling in Liquid Fluidized Beds', NA, 19-38 (2003) [B1] | |||||||

| Show 6 more chapters | ||||||||

Conference (116 outputs)

| Year | Citation | Altmetrics | Link | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2024 |

Wright B, Galvin K, Firouzi M, 'Mitigating the Adverse Effect of Salts on the Recovery of Fine Particles in Flotation', Impc 2024 31st Impc International Mineral Processing Congress, 2714-2722 (2024)

|

||||||||||

| 2024 | Galvin KP, 'Application of the Boycott Effect in Maximizing Grade and Recovery', XXXI International Mineral Processing Congress 2024 Proceedings, 54-62 (2024) [E1] | ||||||||||

| 2024 |

Diba MF, Starrett J, Weatherley D, Runge K, Galvin K, 'A Computational Study on the Hydrodynamics and Particle Transport in a Laboratory-Scale Reflux Classifier', XXXI International Mineral Processing Congress 2024 Proceedings, 1986-1996 (2024) [E1]

|

||||||||||

| 2020 |

Lowes CP, Zhou J, McGrath TDH, Eksteen JJ, Galvin KP, 'Characterising the amenability of gold ore for gravity pre-concentration using LST fluidization in the reflux classifier', SME Annual Conference & Expo 2020, 150-157 (2020) [E1]

|

Open Research Newcastle | |||||||||

| 2019 |

Borrow DJ, Van Netten K, Galvin KP, 'Ultrafast agglomeration using a novel binder in a continuous plug flow system', IMPC 2018 - 29th International Mineral Processing Congress, 2406-2412 (2019) [E1]

|

Open Research Newcastle | |||||||||

| 2019 |

Hunter DM, Lowes CP, Zhou J, Iveson SM, Galvin KP, 'Multistage gravity separation of dense minerals using the reflux™ classifier', IMPC 2018 - 29th International Mineral Processing Congress, 2248-2261 (2019) [E1]

|

Open Research Newcastle | |||||||||

| 2019 |

Carpenter JL, Iveson SM, Zhou Z, Sutherland J, Galvin KP, 'Influence of Slimes on Gravity Separation of Iron Ore Fines in a REFLUXTM Classifier', Proceedings Iron Ore 2019, 685-692 (2019) [E1]

|

Open Research Newcastle | |||||||||

| 2019 |

De Iuliis G, Sahasrabudhe G, Borrow DJ, Galvin KP, 'Investigation of a Novel Emulsion Binder for Recovering Ultrafine Hydrophobic Particles', Chemeca 2019: Chemical Engineering Megatrends and Elements, 119-127 (2019) [E1]

|

Open Research Newcastle | |||||||||

| 2018 |

Cole M, Galvin K, Dickinson J, 'An investigation into enhancing fine particle recovery using a recycle load in the Reflux Flotation Cell', Chemeca 2018, 151.1-151.9 (2018)

|

||||||||||

| 2018 | Neville F, Moreno-Atanasio R, Galvin K, 'Unique particle tracers for identifying chemical engineering products and processes', Chemeca 2018, 1-10 (2018) [E1] | Open Research Newcastle | |||||||||

| 2017 | Hunter D, Iveson S, Galvin KP, 'A Batch Elutriation Technique for the Density-Based Fractionation of Iron Ore', Proceedings Iron Ore 2017, 195-204 (2017) [E1] | Open Research Newcastle | |||||||||

| 2017 | Kumar D, Iveson SM, Galvin KP, 'A Novel Sink-Hole Fluidization Method for Dry Separation of Iron Ore Fines', Proceedings Iron Ore 2017, 221-226 (2017) [E1] | Open Research Newcastle | |||||||||

| 2017 | Carpenter JL, Iveson SM, Galvin KP, 'Separation of ultra-fine particles using the REFLUX™ Graviton', Proceedings Iron Ore 2017, 141-148 (2017) [E1] | Open Research Newcastle | |||||||||

| 2017 |

Hunter DM, Zhou J, Iveson S, Galvin KP, 'Influence of Shear Rate on Separation of Iron Ore Fines Using the REFLUX™ Classifier', Proceedings Iron Ore 2017, 205-210 (2017) [E1]

|

Open Research Newcastle | |||||||||

| 2016 | Syed N, Galvin K, Moreno-Atanasio R, 'Segregation-Dispersion Model of a Fluidized Bed System Incorporating Inclined Channels Operated with no Shear Induced Lift', CHEMECA 2016: Chemical Engineering - Regeneration, Recovery and Reinvention, 570-580 (2016) [E1] | Open Research Newcastle | |||||||||

| 2016 | Galvin KP, Ernst TP, Van Netten K, 'Ultrafast recovery of hydrophobic particles using a novel hydrophobic binder medium', Proceedings of the XXVIII International Mineral Processing Congress (IMPC 2016) (2016) [E1] | Open Research Newcastle | |||||||||

| 2016 |

Dickinson JE, Neville F, Ireland P, Galvin K, 'Uncoupling the inherent bubble-liquid hydrodynamics of conventional ion flotation', CHEMECA 2016: Chemical Engineering - Regeneration, Recovery and Reinvention, 100-107 (2016) [E1]

|

Open Research Newcastle | |||||||||

| 2016 | van Netten K, Ernst T, Moreno-Atanasio R, Galvin KP, 'Fast and Selective Fine Coal Agglomeration Using an Economic Binder', Sixteenth Conference Proceedings Australian Coal Preparation Conference (2016) [E1] | Open Research Newcastle | |||||||||

| 2016 |

Hunter DM, Iveson SM, Galvin KP, 'Measuring grade-recovery and partition curves of dense minerals by batch fractionation in a laboratory-scale reflux™ classifier', XXVIII International Mineral Processing Congress (IMPC 2016). Proceedings of the XXVIII International Mineral Processing Congress (IMPC 2016), 2016-September, 3934-3942 (2016) [E1]

|

Open Research Newcastle | |||||||||

| 2015 | Syed N, Dickinson J, Galvin KP, Moreno-Atanasio R, 'A Continuum simulation model for the Reflux Classifier', Proceedings of APCCHE 2015 Congress Incorporating Chemeca 2015, 3135427-3135427 (2015) [E1] | Open Research Newcastle | |||||||||

| 2015 |

Sutherland JL, Dickinson JE, Galvin KP, 'Examining the partitioning of coal particles in the Reflux Flotation Cell', Proceedings of APCCHE 2015 Congress Incorporating Chemeca 2015, 2309-2316 (2015) [E1]

|

Open Research Newcastle | |||||||||

| 2015 |

Sutherland J, Dickinson JE, Galvin KP, 'Partitioning of coal tracer particles in the Reflux Flotation Cell', Australiasian Particle Technology Society Student Cenference (2015) [E3]

|

||||||||||

| 2015 |

Ireland PM, Webber GB, Jarrett ED, Galvin KP, 'Interaction of a particle bed with a droplet under an applied electric field', Journal of Physics: Conference Series, 646 (2015) [E1]

Transport of dry solid particles to a liquid is relevant to a number of emerging applications, including 'liquid marbles'. We report experiments where the tra... [more] Transport of dry solid particles to a liquid is relevant to a number of emerging applications, including 'liquid marbles'. We report experiments where the transport of dry particles to a pendent water droplet is driven by an external electric field. Both hydrophilic and hydrophobic materials (silica, PMMA) were studied. For silica particles (hydrophilic, poorly conductive), a critical applied voltage initiated transfer, in the form of a rapid 'avalanche' of a large number of particles. The particle-loaded drop then detached, producing a metastable spherical agglomerate. Pure PMMA particles did not display this 'avalanche' behaviour, and when added to silica particles, appeared to cause aggregation and change the nature of the transfer mechanism. This paper is largely devoted to the avalanche process, in which deformation of the drop and radial compaction of the particle bed due to the electric field are thought to have played a central role. Since no direct contact is required between the bed and the drop, we hope to produce liquid marble-type aggregates with layered structures incorporating hydrophilic particles, which has not previously been possible.

|

Open Research Newcastle | |||||||||

| 2015 |

Hunter DM, Zhou J, Iveson SM, Galvin KP, 'Gravity separation of ultra-fine iron ore in the Reflux Classifier', Iron Ore 2015: Maximising Productivity, 143-148 (2015) [E1]

|

Open Research Newcastle | |||||||||

| 2015 |

Galvin KP, Roberts A, Loo CE, Evans GM, Williams K, Iveson SM, 'Australian Research Council Research Hub for Advanced Technologies for Australian Iron Ore - an introduction', Iron Ore 2015: Maximising Productivity, 7-12 (2015) [E2]

|

Open Research Newcastle | |||||||||

| 2014 |

Honaker R, Dunne RC, Galvin K, 'Density-based separation innovations in coal and minerals processing applications', Mineral Processing and Extractive Metallurgy 100 Years of Innovation, 243-264 (2014)

Density-based separators have been used as a preferred method of concentrating minerals and upgrading coal for several centuries. However, significant technological adv... [more] Density-based separators have been used as a preferred method of concentrating minerals and upgrading coal for several centuries. However, significant technological advances continue to be developed and introduced into commercial practice. The main focus of development has been the improvement in separation efficiency over a larger particle size range and the ability to achieve effective density-based separations for particles as small as 10 microns. The success of enhanced gravity separators in the recovery of ultrafine particles has resulted in their implementation into grinding circuits in an effort to prevent overgrinding and reduce circulating loads while also reducing the consumption of the chemicals used in conventional recovery processes and circuits. A review of recent innovations in density-based separations is provided in this publication along with the impact on the strategies and circuits used to process a wide range of minerals and coal.

|

||||||||||

| 2014 | Dickinson J, Galvin K, 'Hydrodynamic enhancement of flotation using a Reflux Flotation Cell', XXVII IMPC 2014, 5-1-5-10 (2014) [E1] | Open Research Newcastle | |||||||||

| 2014 | Dickinson JE, Jiang K, Galvin KP, 'Fast Flotation of Fine Coal', Chemeca 2014: Processing excellence; Powering our future, 838-847 (2014) [E1] | Open Research Newcastle | |||||||||

| 2014 |

Galvin KP, Iveson SM, 'Gravity separation and flotation of fine particles using the Reflux Classifier platform', International Mineral Processing Congress XXVII Proceedings, 1-1 (2014) [E1]

|

Open Research Newcastle | |||||||||

| 2013 |

Kiani A, Zhou J, Galvin KP, 'Gravity Separation of Cenospheres using a Laboratory Inverted Reflux Classifier', Australasian Particle Technology Society Student Conference 2013 (2013) [E3]

|

||||||||||

| 2013 | Jiang K, Dickinson JE, Galvin KP, 'Hydrodynamic Study of a Novel Flotation Cell - The Reflux Flotation Cell', Australiasian Particle Technology Scoiety Student Cenference 2013 (2013) [E3] | ||||||||||

| 2013 | Van Netten K, Moreno-Atanasio R, Galvin KP, 'Enhanced Recovery of Fine Coal Particles using a Modified Oil Agglomeration Process', Australiasian Particle Technology Scoiety Student Conference 2013 (2013) [E3] | ||||||||||

| 2013 |

Marveh F, Doroodchi E, Galvin KP, 'Experimental Validation of a Novel Model for Sediment Consolidation', Australiasian Particle Technology Society Student Conference 2013 (2013) [E3]

|

||||||||||

| 2013 |

Williams L, Hollis J, Collins CE, Morgan PJ, 'Can a relatively low intensity, Motivational Interviewing based intervention prevent weight gain in mid-age women? Outcomes of the 40-Something RCT', Nutrition and Dietetics, 24-25 (2013) [E3]

|

Open Research Newcastle | |||||||||

| 2013 | Jiang K, Dickinson JE, Galvin KP, 'The Hydrodynamics of Fast Flotation', Chemeca 2013, 345-350 (2013) [E1] | Open Research Newcastle | |||||||||

| 2013 |

Kiani A, Zhou J, Galvin KP, 'Upgrading of Positively Buoyant Particles Using an Inverted Reflux Classifier', Chemeca 2013, 357-362 (2013) [E1]

|

Open Research Newcastle | |||||||||

| 2013 | Van-Netten K, Moreno-Atanasio R, Galvin KP, 'Preparation of Coal Agglomerates using a Water-in-Oil Emulsion', Chemeca 2013, 1-5 (2013) [E1] | Open Research Newcastle | |||||||||

| 2013 |

Forghani M, Doroodchi E, Galvin KP, 'Universal Scaling of Consolidation in Batch Settling', Chemeca 2013, 1-7 (2013) [E1]

|

Open Research Newcastle | |||||||||

| 2012 |

Liyanaarachchi KR, Webber GB, Galvin KP, 'Selective collection of fine particles by water drops', 2012 AIChE Annual Meeting (2012) [E3]

|

||||||||||

| 2012 | Galvin KP, Dickinson JE, 'Particle segregation in a liquid fluidized bed incorporating inclined channels subjected to centrifugal forces', 2012 AIChE Annual Meeting, AIChE 2012 (2012) [E3] | ||||||||||

| 2012 |

Galvin KP, Zhou ZQ, 'Application of the reflux classifier for measuring gravity recoverable product', Separation Technologies for Minerals, Coal and Earth Resources, -, 153-161 (2012) [E1]

|

Open Research Newcastle | |||||||||

| 2010 |

Galvin KP, Webber GB, Mason M, Liyanaarachchi KR, 'Inverse flotation - A new method of fine particle beneficiation', Chemeca 2010: Proceedings of the 40th Australasian Chemical Engineering Conference (2010) [E1]

|

Open Research Newcastle | |||||||||

| 2010 |

Galvin KP, Walton KJ, Zhou ZQ, 'Gravity separation and classification of fine coal using the hydrodynamics of inclined channels', Proceedings of the Thirteenth Australian Coal Preparation Conference, 224-235 (2010) [E1]

|

Open Research Newcastle | |||||||||

| 2010 |

Galvin KP, Walton K, Zhou ZQ, 'Fine gravity separation in the reflux classifier, exploiting a high shear rate, laminar flow mechanism', XXV International Mineral Processing Congress [electronic resource] : IMPC 2010,, 729-738 (2010) [E1]

|

Open Research Newcastle | |||||||||

| 2009 |

Galvin KP, Walton KJ, Zhou ZQ, 'Application of closely spaced inclined channels in gravity separation', 8th World Congress of Chemical Engineering 2009, 1-6 (2009) [E2]

|

Open Research Newcastle | |||||||||

| 2009 |

Walton KJ, Zhou ZQ, Galvin KP, 'Processing of fine particles using closely inclined channels', CHEMECA 2009: Engineering Our Future: Are We Up to the Challenge?: CD with Proceedings, -, 1-10 (2009) [E1]

|

Open Research Newcastle | |||||||||

| 2008 | Galvin K, 'Water efficient landscape rebate pilot prog', American Water Works Association Conference and Exposition on Sustainable Water Sources Conservation and Resource Planning 2008, 1242-1255 (2008) | ||||||||||

| 2008 |

Van Netten K, Zhou ZQ, Galvin KP, 'On the motion of aggregates composed of different numbers of particles through a non-uniform magnetic field', Chemeca2008, 818-822 (2008) [E1]

|

Open Research Newcastle | |||||||||

| 2008 | Dickinson JE, Laskovski D, Galvin KP, 'Conventional steady state recovery and enrichment of surfactant through foam fractionation', Chemeca2008, 1-11 (2008) [E1] | Open Research Newcastle | |||||||||

| 2008 | MacPherson SA, Galvin KP, 'The effect of vibration on dry coal beneficiation in the reflux classifier', 25th International Pittsburgh Coal Conference CD-ROM Proceedings, 1-10 (2008) [E2] | ||||||||||

| 2008 | MacPherson SA, Callen AM, Walton KJ, Galvin KP, 'Dry processing of coal in an air-sand dense-medium reflux classifier with vibration', Proceedings of the Twelfth Australian Coal Preparation Conference: Cleaning Coal to Secure Our Future, 462-465 (2008) [E3] | ||||||||||

| 2008 |

Walton KJ, Zhou ZQ, Galvin KP, 'Gravity separation of flotation feed using the enhanced reflux classifier', Proceedings of the Twelfth Australian Coal Preparation Conference: Cleaning Coal to Secure Our Future, 478-480 (2008) [E3]

|

||||||||||

| 2007 |

Callen AM, Patel BK, Zhou ZQ, Galvin KP, 'Investigation of a water based method for determining coal washability data', Proceedings of the Eleventh Australian Coal Preparation Conference, 154-165 (2007) [E2]

|

||||||||||

| 2007 |

Galvin KP, Munro M, Jones E, Zhou ZQ, 'Gravity concentration of coarse coal using the reflux classifier under dilute semi-batch conditions', Proceedings of the Eleventh Australian Coal Preparation Conference, 126-138 (2007) [E2]

|

||||||||||

| 2007 |

Evans GM, Galvin KP, Doroodchi E, 'Introducing quantitative life cycle analysis into the chemical engineering curriculum', CHEMECA 2007: Academia and Industry Strengthening the Profession. Proceedings, 963-970 (2007) [E1]

|

||||||||||

| 2007 |

McKay M, Moghtaderi B, Galvin KP, 'Drying Applications for the Reflux Classifier', CHEMECA 2007: Academia and Industry Strengthening the Profession. Proceedings, 494-502 (2007) [E1]

|

||||||||||

| 2007 |

Brinch JF, Moghtaderi B, Galvin KP, 'Translational and rotational motion of cylinders down narrow inclined channels at low reynolds numbers', CHEMECA 2007: Academia and Industry Strengthening the Profession. Proceedings, 523-529 (2007) [E1]

|

||||||||||

| 2007 |

MacPherson SA, Moghtaderi B, Walton KJ, Galvin KP, 'Dry processing using an air-magnetite dense medium in the reflux classifier', CHEMECA 2007: Academia and Industry Strengthening the Profession. Proceedings, 1959-1964 (2007) [E1]

|

||||||||||

| 2007 |

Moghtaderi B, Galvin KP, 'Comparison of partial oxidation and auto-thermal reforming of methane for production of hydrogen in a novel micro-reactor', Proceedings of the Australian Combustion Symposium 2007, 142-145 (2007) [E1]

|

||||||||||

| 2007 |

Laskovski D, Zhou ZQ, Stevenson P, Galvin KP, 'Application of the reflux classifier correlation to the hydraulic conveying of particles up steep inclines', Hydrotransport 17. The 17th International Conference on the Hydraulic Transport of Solids. Proceedings, 589-599 (2007) [E1]

|

||||||||||

| 2006 |

Munro M, Zhou ZQ, Galvin KP, 'Potential Benefits from Operating the Reflux Classifier Using a Coarser Feed', Proceedings, XV International Coal Preparation Congress and Exhibition, - (2006) [E2]

|

||||||||||

| 2006 |

Callen AM, Patel BK, Zhou ZQ, Galvin KP, 'Coal Washability Analysis by Water Fluidization and Jigging', Proceedings, XV International Coal Preparation Congress and Exhibition, - (2006) [E2]

|

||||||||||

| 2006 |

Sucker AL, Zhou ZQ, Galvin KP, 'Influence of a Magnetic Field Gradient on the Motion of Spherical Particles', Conference Proceedings, CHEMECA 2006, - (2006) [E1]

|

||||||||||

| 2005 |

Laskovski D, Stevenson P, Zhou ZQ, Galvin KP, 'Distribution of Life Forces on a Single Particle Exhibiting Sporadic Movement during Hydraulic Conveying', CHEMECA 2005 : proceedings, - (2005) [E1]

|

||||||||||

| 2005 |

Callen AM, Moghtaderi B, Galvin KP, 'Use of a Binary System of Particles to Investigate Particle Retention in a Gas Fluidised Bed Containing Parallel Inclined Plates', Particulate Systems Analysis 2005, - (2005) [E2]

|

||||||||||

| 2004 |

Galvin KP, Doroodchi E, Callen AM, Moghtaderi B, Fletcher DF, Zhou ZQ, 'Development of a New Fluidized Bed Containing Inclined Plates', Proceedings, 12th International Conference on Transport & Sedimentation of Solid Particles, 319-325 (2004) [E1]

|

||||||||||

| 2004 |

Evans G, Scaife P, Maddox B, Galvin K, 'Using a "campus as a classroom concept" to highlight sustainability practice to engineers and scientists', Developments in Chemical Engineering and Mineral Processing, 12, 383-392 (2004)

Chemical engineering at the University of Newcastle has introduced a "Systems Thinking" approach in response to the changing needs of today's young engin... [more] Chemical engineering at the University of Newcastle has introduced a "Systems Thinking" approach in response to the changing needs of today's young engineers, particularly in relation to sustainable development and interaction with the wider community. The basic concepts are reinforced to the students in the form of case studies. The activities cover a broad range of traditional chemical engineering principles, including fluid mechanics, heat and mass transfer, process flowsheeting, and design. The case studies have the additional dimensions of life cycle modelling, environmental impact assessment, and direct interaction with the broader community. In this paper, two examples, involving Building Design and On-Site Water Management, are presented, including a brief description, desired learning outcomes, results and general observations. Generally, it was found that the case studies provided an excellent framework for establishing a systems approach to arriving at solutions, and acted as a focus for quantitative analysis using the various tools taught during the course. Most importantly, the material presented assisted students to understand the practices which contribute to the transition to a sustainable society.

|

||||||||||

| 2004 | Galvin KP, 'Washability Analysis of Coal using Water Fluidization', Energeia, 15:5, 1-6 (2004) [E2] | ||||||||||

| 2004 |

Doroodchi E, Galvin KP, Fletcher DF, 'The Influence of Inclined Plates on Expansion Behaviour of Solid Suspensions in a Liquid Fluidised Bed - A Computational Fluid Dynamics Study', 32nd Australasian Chemical Engineering Conference, - (2004) [E1]

|

||||||||||

| 2004 |

Callen AM, Moghtaderi B, Galvin KP, 'Retention of Particles in a High Velocity Gas Fluidised Bed Containing Parallel inclined Plates', 32nd Australasian Chemical Engineering Conference (2004) [E1]

|

||||||||||

| 2004 |

Zhou ZQ, Laskovski D, Stevenson P, Galvin KP, 'Time Series Analysis of the Sporadic Motion of a Single Particle at the Threshold of Hydraulic Conveying', 32nd Australasian Chemical Engineering Conference, - (2004) [E1]

|

||||||||||

| 2004 |

Doroodchi E, Zhou ZQ, Fletcher DF, Galvin KP, 'Influence of Inclined Plates on Separation Behaviour of Fluidised Suspensions - Enhanced Elutriation', Proceedings of the 11th International Conference on Fluidization (2004) [E1]

|

||||||||||

| 2004 |

Galvin KP, Callen AM, Zhou ZQ, Doroodchi E, 'Gravity Separation using a Full-Scale Reflux Classifier', Proceedings of the Tenth Australian Coal Preparation Conference, 258-263 (2004) [E1]

|

||||||||||

| 2003 |

Callen AM, Moghtaderi B, Galvin KP, 'Particle Classification in a Novel Gas-Solid Classifier', The 31st Australasian Chemical Engineering Conference, CD (2003) [E1]

|

||||||||||

| 2002 | Callen AM, Pratten SJ, Belcher SM, Lambert N, Galvin KP, 'A new method for washability analysis of fine coal particles using water fluidisation', Proceedings of the Ninth Australian Coal Preparation Conference (2002) [E1] | ||||||||||

| 2002 |

Galvin KP, Belcher SM, Callen AM, Lambert N, Doroodchi E, Nguyen Tram Lam G, Pratten SJ, 'Gravity separation and hydrosizing using the reflux classifier', Proceedings of the Ninth Australian Coal Preparation Conference (2002) [E1]

|

||||||||||

| 2002 |

Evans GM, Habgood MG, Galvin KP, Biggs SR, 'A description of dynamic interfacial adsorption', Proceedings of the 9th APCChE Congress and CHEMECA 2002 (2002) [E1]

|

||||||||||

| 2002 |

Evans GM, Middlebrook PD, Scaife PH, Maddox BA, Galvin KP, Pollard P, 'Using the', Proceedings of the 9th APCChE Congress and CHEMECA 2002 (2002) [E1]

|

||||||||||

| 2002 |

Wigman JLA, Evans GM, Galvin KP, 'A new method for measurement of interfacial mass transfer', Proceedings of the APCChE Congress and CHEMECA 2002 (2002) [E1]

|

||||||||||

| 2002 | Callen AM, Pratten SJ, Lambert N, Galvin KP, 'Measurement of the density distribution of a system of particles using water fluidisation', Proceedings, World Congress on Particle Technology 4 (2002) [E1] | ||||||||||

| 2002 |

Doroodchi E, Fletcher DF, Galvin KP, 'Effect of inclined plates on separation behaviour of binary-solid particles in a liquid fluidised bed', Proceedings, World Congress on Particle Technology 4 (2002) [E1]

|

||||||||||

| 2002 |

Franks GV, Iveson SM, Middlebrook PD, Galvin KP, Evans GM, 'Particle Technology in the undergraduate chemical engineering program at the University of Newcastle', Proceedings, World Congress on Particle Technology 4 (2002) [E1]

|

||||||||||

| 2001 |

Evans GM, Galvin KP, Wibberley LJ, Scaife PH, Lucas JA, Hooker C, 'Life cycle analysis and sustainability in the undergraduate degree course of the University of Newcastle', Proceedings, 6th World Congress of Chemical Engineering (2001) [E1]

|

||||||||||

| 2001 |

Wigman JLA, Evans GM, Galvin KP, 'The dynamics of gas bubble dissolution in the presence of a surfactant', Proceedings, 6th World Congress of Chemical Engineering (2001) [E1]

|

||||||||||

| 2001 | Galvin KP, Callen AM, Lambert N, Nguyen Tram Lam G, Pratten SJ, 'Hydraulc sizing of small coal using the reflux classifier', Eighteenth Annual International Pittsburgh Coal ConferenceProceedings (2001) [E2] | ||||||||||

| 2000 |

Galvin KP, Doroodchi E, 'Development of a novel crystallizer', 28th Australasian Chemical Engineering Conference (2000) [E1]

|

||||||||||

| 2000 | Nguyen Tram Lam G, Galvin KP, 'Deveopment of an innovative classifier', 28th Australasian Chemical Engineering Conference (2000) [E1] | ||||||||||

| 2000 | Keane M, Bowyer M, Biggs SR, Galvin KP, 'The relationship between particle size and creaminess in microfluidized low fat dairy emulsions', 28th Australasian Chemical Engineering Conference (2000) [E1] | ||||||||||

| 2000 |

Evans GM, Galvin KP, Lucas JA, 'Life cycle analysis in the undergraduate degree course at the University of Newcastle', 28th Australasian Chemical Engineering Conference (2000) [E1]

|

||||||||||

| 1999 |

Keane MA, McMillan W, Bowyer MC, Galvin KP, Biggs S, Hosken RW, 'Microsctructure and sensory investigation of frozen deserts containing pectin', 10th World COngress of Food Science & Technology Abstracts (1999) [E3]

|

||||||||||

| 1999 | Liu J, Galvin KP, Tian Z, Huan B, 'Tube to solids heat transfer rate in the solids return standpipe of a circulating fluidized bed', 27th Australasian Chemical Engineering Conference (1999) [E1] | ||||||||||

| 1999 | Galvin KP, Zhao Y, Davis RH, 'Hydrodynamic roughness of non-colloidal spherical particles in low Reynolds number motion down an incline', 27th Australasian Chemical Engineering Conference (1999) [E1] | ||||||||||

| 1999 | Keane M, McMillan W, Bowyer M, Galvin KP, Biggs S, Hosken R, 'Laser scanning confocal microscopy of a dairy based emulsion', 27th Australasian Chemical Engineering Conference (1999) [E1] | ||||||||||

| 1999 |

Galvin KP, Pratten SJ, 'Application of fluidization to obtain washability data', Minerals Engineering (1999) [E1]

|

||||||||||

| 1999 |

Galvin KP, Pratten SJ, Nicol SK, 'Dense medium separation using a teetered bed separator', Minerals Engineering (1999) [E1]

|

||||||||||

| 1998 |

Duewell MR, Forrester SE, Galvin KP, Evans GM, 'Prediction of the Droplet Size in a Liquid-Liquid Jet Mixer Emulsification Unit', Proceedings of the 26th Australasian Chemical Engineering Conference (1998) [E1]

|

||||||||||

| 1998 | Macaulay B, Galvin KP, Biggs S, 'Static and Dynamic Friction:The Motion of a Concentrated Dispersion', Proceedings of the 26th Australasian Chemical Engineering Conference (1998) [E1] | ||||||||||

| 1998 | Liu J, Galvin KP, 'The Motion of Particle Clusters Down an Incline on a Moving Monolayer of Particles', Proceedings of the 26th Australasian Chemical Engineering Conference (1998) [E1] | ||||||||||

| 1998 | Swanson AR, Drummond RB, Galvin KP, Mullins PJ, 'Impact of Coal Variability on Plant Operations and Design', Proceedings of the XIII International Coal Preparation Congress (1998) [E1] | ||||||||||

| 1998 | Galvin KP, Pratten SJ, Nguyen Tram Lam G, Nicol SK, 'Dynamics of a Teetered Bed Deparator', Proceedings of the XIII International Coal Preparation Congress (1998) [E1] | ||||||||||

| 1998 | Galvin KP, Nicol SK, Veal CJ, 'Residual Moisture Reduction Through the Development of an Air Purge Centrifuge', Proceedings of the XIII International Coal Preparation Congress (1998) [E1] | ||||||||||

| 1998 | Galvin KP, Pratten SJ, Nguyen Tram Lam G, 'Differential Settling in a Teeter Bed Separator', World Congress on Particle Technology 3 (1998) [E1] | ||||||||||

| 1998 | Liu J, Galvin KP, 'Hydrodynamic Drag on Particle Assemblies Travelling Down Inclined Tubes', World Congress on Particle Technology 3 (1998) [E1] | ||||||||||

| 1998 | Flemming B, Macauley B, Galvin KP, Biggs S, 'Static and Dynamic Adhesional Properties of a Concentrated Dispersion', World Congress on Particle Technology 3 (1998) [E1] | ||||||||||

| Show 113 more conferences | |||||||||||

Journal article (173 outputs)

| Year | Citation | Altmetrics | Link | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2026 |

Galvin KP, Guner M, Kowalczuk P, 'Comments On: Impact assessment and optimization of REFLUX flotation cell (RFC) primary settings on copper sulfide ore flotation (Guner and Kowalczuk, Minerals Engineering, 233, 109653, 2025)', Minerals Engineering, 235 (2026)

|

||||||||||

| 2026 |

Saffarian H, Galvin KP, Firouzi M, 'Rethinking silver recovery pathways in end-of-life photo voltaic recycling using froth flotation', Minerals Engineering, 242, 110189-110189 (2026)

|

||||||||||

| 2025 |

Amosah ME, Zhou J, Galvin KP, 'Fourth generation gravity separation using the Reflux Classifier', Minerals Engineering, 224 (2025) [C1]

The Reflux Classifier achieves powerful synergy between an upper system of inclined channels and lower fluidised bed arrangement, delivering gravity separation in a sin... [more] The Reflux Classifier achieves powerful synergy between an upper system of inclined channels and lower fluidised bed arrangement, delivering gravity separation in a single stage of separation. This paper is concerned with the step-change improvement in gravity separation utilising the latest in a series of improvements. The laminar-shear separation mechanism led to the introduction of closely-spaced inclined channels, nominally 6 mm, solving a previously intractable problem in concentrating metallurgical coal. The more recent shift to a spacing of 3 mm, and even 1.8 mm has delivered a further step change in the separation of gangue minerals from dense minerals. In this new work, we have introduced changes to the lower fluidised bed, removing the fluidisation distributor and installing a slow-moving rake with water addition. This change produced a much more robust fluidisation boundary condition, removing the vagaries of the minimum fluidisation condition, producing a stronger dense medium effect, hence significant step change in gravity separation performance well beyond anything that was previously possible. This step change in performance reveals a direct pathway from a feed grade of 0.32 wt% tin to a significant recovery of the tin at a grade higher than 40 wt%.

|

||||||||||

| 2025 |

Saffarian H, Galvin K, Firouzi M, 'A Critical Review of Leaching Pathways for Silver Recovery from EoL Photovoltaic Modules and Prospects for Flotation', Mineral Processing and Extractive Metallurgy Review (2025) [C1]

|

||||||||||

| 2025 |

Wright B, Amani P, Galvin K, Firouzi M, 'Mechanisms of gangue transport and recovery in Reflux flotation cells under varying bias flux and salinity conditions', Minerals Engineering, 234 (2025) [C1]

|

||||||||||

| 2025 |

Galvin KP, Zhou J, Rodrigues AFDV, 'Single stage production of ultra-high-grade iron ore using a novel fluidisation arrangement in a Reflux Classifier', Minerals Engineering, 233 (2025) [C1]

|

||||||||||

| 2025 |

Wright B, Amani P, Galvin K, Firouzi M, 'Mitigating the Adverse Effect of Salts on Gangue Recovery Using a Reflux Flotation Cell', Mineral Processing and Extractive Metallurgy Review (2025) [C1]

Salts can negatively affect the froth flotation process by increasing the recovery of unwanted gangue particles. This study investigated the effect of salt on gangue re... [more] Salts can negatively affect the froth flotation process by increasing the recovery of unwanted gangue particles. This study investigated the effect of salt on gangue recovery and evaluated the effectiveness of counter-current washing using unique system hydrodynamics distinct from conventional flotation cells, to mitigate this issue in saline water environments. Experiments were conducted using a Reflux flotation cell (RFC¿) with fine hydrophilic silica particles (with a D90 of 68 µm) as a model for gangue particles at two solid concentrations of 3 wt.% and 12 wt.% and using sodium chloride 1 M reflecting the predominant salt composition in plant water. A single-mineral flotation approach was employed to isolate the effect of system hydrodynamics on gangue recovery, minimizing interference from ion-particle-collector interactions in saline environments. Key parameters such as yield and system hydrodynamics including bubble size and gas holdup were analyzed across a range of gas and wash water fluxes in the presence and absence of salt. In the absence of salt and counter-current washing, silica recovery (yield) reached 13.8%±0.21. This value increased by approximately 6.5% of the initial recovery when 1 M NaCl was introduced, attributed to salt-induced aggregation of fine silica particles through electrostatic double-layer screening. The application of counter-current washing in the presence of salt reduced silica recovery by 90%, resulting in a final recovery of less than 1.5%. This significant reduction is attributed to the formation of salt-induced agglomerates that are more effectively removed through washing. This trend was observed for both 12 wt.% solid concentration and the relatively dilute feed (3 wt.%). To investigate the potential hydrophobizing effect of salt on silica, surface wettability was measured with and without salt, showing minimal or no change in wettability. These findings highlight the potential of the RFC in mitigating the adverse effects of salts on gangue recovery, offering a promising approach for improving flotation performance in saline water.

|

||||||||||

| 2025 |

Parkes S, Wang P, Galvin KP, 'Benchmarking a Single-Stage REFLUX™ Flotation Cell Against a Multi-Stage Industrial Copper Concentrator and Lab-Scale Mechanical Cell', Minerals, 15 (2025) [C1]

|

||||||||||

| 2025 |

Wright B, Galvin K, Firouzi M, 'Effect of gas flux on gangue recovery in a reflux flotation cell - a modelling and experimental study', Powder Technology, 455 (2025) [C1]

Gangue particles, which are typically hydrophilic, impede the efficient recovery of valuable hydrophobic particles in flotation cells, and in turn lower the grade of th... [more] Gangue particles, which are typically hydrophilic, impede the efficient recovery of valuable hydrophobic particles in flotation cells, and in turn lower the grade of the final concentrate. The system hydrodynamics, including the gas and liquid fluxes, and bubble segregation, plays a key role in the efficient separation of the valuable and gangue mineral particles. In conventional flotation cells, an increase in the gas flux leads to increased entrainment of the gangue minerals, due to an increase in water recovery. This new work investigates the effects of the gas flux and liquid fluxes on gangue entrainment in a Reflux Flotation Cell (RFC), a novel system that incorporates parallel inclined channels to prevent bubble losses to tailings. The study focused exclusively on fine hydrophilic silica as the model gangue mineral in the feed, completely excluding hydrophobic particles. Rigorous, continuous, steady state experiments produced an accurate measure of the particle transport into the concentrate. It was concluded that the wash water addition removed the bulk entrainment. Hence, the observed entrainment was primarily due to bubble surface entrainment. Interestingly, the silica entrainment decreased with increasing the gas flux and wash water flux. The system hydrodynamics was quantified through measurement of the gas hold-up and the bubble size distribution. Drift flux theory was applied to these accurate datasets, confirming the significant role of enhanced segregation of the bubbles due to the presence of the inclined channels, an effect known as the Boycott Effect.

|

||||||||||

| 2025 |

Crompton LJ, Islam MT, Gibbs E, Galvin KP, 'A new method for assessing coarse particle flotation performance Part 2: Assessment of reproducibility using data from a mechanical cell', Minerals Engineering, 224 (2025) [C1]

In Part I, we introduced distributed rate constants into the algorithm of Crompton et al (2023) used for describing the partitioning of hydrophobic particles in coarse ... [more] In Part I, we introduced distributed rate constants into the algorithm of Crompton et al (2023) used for describing the partitioning of hydrophobic particles in coarse particle flotation. The Part I paper applied the new algorithm to a previous data set generated using the CoarseAIRTM fluidised bed separator. This Part II paper investigated the uncertainty in the new algorithm. A mechanical cell was used to simulate the coarse particle flotation process, providing a means for preparing pseudo steady state feed, product, and reject samples. A comprehensive protocol for preparing the samples was established. The overall methodology was then repeated multiple times, providing a basis for quantifying the reproducibility and reliability of the methodology, confirming its robustness.

|

||||||||||

| 2025 |

Starrett JB, Galvin KP, 'Application of inclined channels in the hydrodynamic classification of minerals by particle size – Part III – Extension to high volumetric feed fluxes and low concentrations', Minerals Engineering, 231 (2025) [C1]

|

||||||||||

| 2025 |

Starrett JB, Iveson SM, Galvin KP, 'Empirical evidence for Fermi-Dirac classification of minerals by particle size', Minerals Engineering, 227 (2025) [C1]

In mineral processing, partition curves are used to describe the probability of a particle of a given size or density reporting to the overflow or the underflow stream.... [more] In mineral processing, partition curves are used to describe the probability of a particle of a given size or density reporting to the overflow or the underflow stream. One simple descriptor is the Rosin-Rammler (Weibull) functional form, based on a sharpness parameter, a. An alternative descriptor was introduced by Scott and Napier-Munn (1992) based on the simplified Whiten equation expressed in terms of the Ecart probable, Ep. Curiously, this simplified Whiten equation has functional equivalence to the Fermi-Dirac distribution (Fermi, 1926; Dirac, 1926), an exact equation used in quantum mechanics to describe the probability of Fermions residing in either the valency or the conduction band. In this study, the particle size classification data from Starrett and Galvin (2023), produced using the REFLUX¿ Classifier, provided powerful empirical evidence supporting the application of the simplified Whiten equation over the commonly used Rosin-Rammler function. The raw data adhered to the simplified Whiten equation over a range of ± 5Ep, much wider than the Rosin-Rammler function. Hence the simplified Whiten equation, with its equivalence to the fundamental Fermi-Dirac distribution, offers prospects for a stronger theoretical framework for describing the role of a hydrodynamic driving force in particle size classification.

|

||||||||||

| 2025 |

Starrett JB, Galvin KP, 'Application of inclined channels in the hydrodynamic classification of minerals by particle size - Extension to coarser separations', MINERALS ENGINEERING, 222 (2025) [C1]

A REFLUX¿ Classifier was used to classify a silica feed (0¿710 µm) based on particle size. Split Fluidisation was used to generate remarkably sharp separations involvin... [more] A REFLUX¿ Classifier was used to classify a silica feed (0¿710 µm) based on particle size. Split Fluidisation was used to generate remarkably sharp separations involving solids throughputs of up to 92 t/m2/h. This work builds on the previous study by Starrett and Galvin (2023) but with a focus on coarser separations at higher throughputs. As the separation size increased, there was increasing misplacement of fine particles in excess of 75 µm into the coarse underflow stream. This problem was averted by halving the cross-sectional area of the lower section of the REFLUX¿ Classifier. This change led to a doubling of the superficial fluid velocity in the lower section for a given set of flow rates, ensuring fine particles were unable to settle into the coarse underflow. In general, the separations performed in this study show complete closure of the partition curve at both the coarse and fine ends. It was also found that to deliver sharp separations it is essential to introduce sufficient water to the separator, per unit of solids transport to the overflow, especially for higher solids throughputs with coarser separations. Although the fluidisation rate can be used to control the separation size at finer separations (below 180 µm) and lower throughputs, ultimately the bias flux provides the basis for controlling the separation size at coarser sizes and higher throughputs.

|

||||||||||

| 2025 |

Ilic D, Lavrinec A, Galvin KP, 'Model investigation of a dry vibrated fluidized sinkhole system for separating coarse particles based on density', MINERALS ENGINEERING, 222 (2025) [C1]

|

||||||||||

| 2024 |

Amosah ME, Yvon M, Zhou J, Galvin KP, 'The role of enhanced desliming and gravity separation as a precursor to flotation in the upgrading of cassiterite from tailings', MINERALS ENGINEERING, 208 (2024) [C1]

Due to the depletion of high-grade mineral deposits, there is increasing demand for the reprocessing of minerals from tailings dams. However, tailings reprocessing can ... [more] Due to the depletion of high-grade mineral deposits, there is increasing demand for the reprocessing of minerals from tailings dams. However, tailings reprocessing can present several challenges due to the presence of slimes: reduced selectivity and kinetics resulting in low recovery, excessive entrainment, and high reagent consumption. This research focussed on a previously intractable problem, the processing of a low-grade cassiterite (SnO2) feed from a tailings dam. Conventional technologies have failed to achieve viable recoveries and saleable grades. Therefore, gravity separation and desliming were applied using the REFLUXTM Classifier and the REFLUXTM Graviton, targeting the tin down to ~ 10 µm, followed by flotation. The REFLUXTM Classifier experiments were performed using an inclined channel spacing of 1.8 mm at ~ 5 t/m2/h and higher. Recoveries of up to 94 % above 20 µm and 50 % below 20 µm were achieved. Importantly, the deslimed product permitted highly effective recovery of the tin by flotation, with final decanted product grades higher than 30 ± 2 wt% tin, and an overall recovery of up to 35 ± 5 %. Desliming with the REFLUXTM Graviton achieved recovery up to 80 %. The scope for further improvement in the grade and recovery is discussed.

|

Open Research Newcastle | |||||||||

| 2024 |

Parkes S, Wang P, Galvin KP, 'Investigating the system flotation kinetics of fine chalcopyrite in a REFLUXTM flotation cell: Part II low-grade ores', MINERALS ENGINEERING, 207 (2024) [C1]

The flotation performance of the REFLUX¿ Flotation Cell (RFC¿) was assessed and quantified through a performance ratio relative to a bench scale mechanical cell. This n... [more] The flotation performance of the REFLUX¿ Flotation Cell (RFC¿) was assessed and quantified through a performance ratio relative to a bench scale mechanical cell. This new work extended the previous study (Parkes et al., 2022) on a model feed to cover two industrial low-grade chalcopyrite feeds, Feed A and Feed B, with Feed B containing a surface-active slime component. The initial phase of the work covered the sensitivity of the performance ratio to the changes in the process conditions in the mechanical cell, notably the gas flux and the feed pulp density. In general, the performance ratio was not very sensitive to the gas flux, mainly due to the need to prevent excessive entrainment which limited the applicable range of gas fluxes. Changes to the feed pulp density had a more significant effect on the performance ratio, hence it is recommended the performance ratio of the two systems be assessed at a similar feed pulp density. For both the low-grade ores, the performance of the RFC¿, relative to the mechanical cell, was found to be very high. For Feed A, the performance ratio increased with the particle size, exceeding a value of 5 beyond a particle size of 10 µm. In general, a gas-to-feed flux ratio of 1:1 was found to be optimal. For Feed B, containing a surface-active slime component, the ratio typically exceeded a value of 10 and was less dependent on the particle size, pulp density and feed rate. Overall, the performance ratio increased as the feed pulp density decreased, suggesting a very strong improvement in the flotation kinetics within the RFCTM at lower pulp densities. While the selectivity of hydrophobic to hydrophilic material recovery was very high for Feed A, it was significantly reduced for Feed B, suggesting that the transport of the hydrophilic particles was assisted by the surface-active slime component in the feed.

|

Open Research Newcastle | |||||||||

| 2024 |

Parkes S, Wright B, Wang P, Stiller E, Firouzi M, Galvin KP, 'Hydrophobic-hydrophilic bubble-particle kinetics in a downcomer', MINERALS ENGINEERING, 210 (2024) [C1]

Declining ore grades have been addressed through exponentially higher cell residence times. With cell sizes approaching 1000 m3, improved kinetics is crucial. Downcomer... [more] Declining ore grades have been addressed through exponentially higher cell residence times. With cell sizes approaching 1000 m3, improved kinetics is crucial. Downcomers, which increase shear rates for improved recovery of fine hydrophobic particles, may also cause a strong deposition flux of ultrafine hydrophilic particles close to the bubble surface, via lubrication forces. Model feeds of varying silica-to-chalcopyrite mass ratios up to 80 were processed using a REFLUX¿ Flotation Cell (RFC¿). Equivalent hydrodynamic conditions were applied, including a low solids concentration of 1 wt% to prevent kinetic limitations due to limited bubble surface area. The hydrophobic particle recovery declined significantly as the silica content increased, with clear evidence the ultrafine hydrophilic silica hindered the adhesion kinetics of the hydrophobic chalcopyrite.

|

Open Research Newcastle | |||||||||

| 2024 |

Iveson SM, Galvin KP, 'Amplification in the Uncertainty of the Yield and Recovery for a Steady-State Mineral Separator calculated using the Two-Product Formula', MINERALS ENGINEERING, 212 (2024) [C1]

This paper presents a simple relationship for estimating the uncertainty in the overall yield and species recovery when the two-product formula is applied to assays of ... [more] This paper presents a simple relationship for estimating the uncertainty in the overall yield and species recovery when the two-product formula is applied to assays of the feed, product and tailings streams of a steady-state mineral separator. The non-linearity of the two-product formula means the reliability of these yield and recovery values can vary significantly. Formal treatment of the problem provides a generalized, albeit complex, expression for the uncertainty (Wills, 1997), limited to relatively small input disturbances. This paper explores the problem further using Monte Carlo simulations, covering the effects of relatively small through to relatively large input disturbances. Assay values for the feed, GF, product, GP, and tailings, GT, were assumed to have the same relative uncertainty. The work focussed on the amplification in the uncertainty of the yield, AY, and recovery, AR, resulting in very simple expressions, AY ~ 2 GF/|GF ¿ GT| and AR ~ 2 GT/|GF ¿ GT|.

|

Open Research Newcastle | |||||||||

| 2024 |

Crompton LJ, Islam MT, Gibbs E, Galvin KP, 'A new method for assessing coarse particle flotation performance Part IOn the deconvolution of the flotation response', MINERALS ENGINEERING, 218 (2024) [C1]

Crompton et al. (2023) developed a new algorithm for describing the performance of coarse particle flotation. They used the flotation rate constant, k, normalised by th... [more] Crompton et al. (2023) developed a new algorithm for describing the performance of coarse particle flotation. They used the flotation rate constant, k, normalised by the maximum rate constant, kmax, for the pure mineral, as a proxy for the fractional surface liberation. The algorithm was used to produce the partition curve for a separation performed by a novel device, the CoarseAIR¿. Part I of this new study re-visits the former work, particularly the batch mechanical flotation responses of the steady state samples from the CoarseAIR¿. The flotation responses were deconvolved to the corresponding distributions of rate constants for the three streams, and in turn used to produce the partition curve for the coarse particle flotation. The algorithm used to produce the distribution of rate constants was driven towards a simple functional form by minimising its overall curvature. The steady state samples from any coarse particle flotation system can be assessed in this way. Part II of this study focuses on the reproducibility of the approach, and hence the uncertainty, using a batch mechanical cell to simulate the coarse particle flotation, and in turn the steady state feed, product and reject samples.

|

Open Research Newcastle | |||||||||

| 2024 |

Rodrigues AFDV, Delboni Junior H, Zhou J, Galvin KP, 'Gravity separation of fine itabirite iron ore using the Reflux Classifier - Part II - Establishing the underpinning partition surface', MINERALS ENGINEERING, 210 (2024) [C1]

This work assessed the potential of a single stage Reflux Classifier to upgrade itabirite iron ore to high grade at satisfactory recovery. Part I reported on the detail... [more] This work assessed the potential of a single stage Reflux Classifier to upgrade itabirite iron ore to high grade at satisfactory recovery. Part I reported on the detailed findings of the experimental program and the physical transport of the particles through the system. A key purpose of the present paper was to deduce the underlying partition surface from relatively basic feed information on the Fe assays obtained as a function of the particle size. Conversion of the feed data into a simple binary description based on the density of hematite and density of silicates was used. This approach then provided a basis for applying the partition surface to a given feed to predict the separation performance. Data from the experiments were compared to values predicted from the partition surface. A least squares objective function was used to implicitly deduce the parameters governing the partition surface, notably the key exponent n and the Écarté Probable, Ep. Across 12 of the experiments, the exponent, n, governing the partition surface was found to be 0.26 ± 0.02. This result was in very good agreement with the value of 0.28 determined previously. The second key parameter, the Ep, was also determined for each of the experiments. The lowest Ep, found to be 365 kg/m3 for a low slimes viscosity, was also in good agreement with the result reported previously for a deslimed feed. This work provides confidence in the application of the partition surface to predict similar dense mineral separations, and stronger insights into the mechanisms responsible for the separation.

|

Open Research Newcastle | |||||||||

| 2024 |

Wang P, Yvon M, Parkes S, Galvin KP, 'Enhancing nickel grade and recovery with counter-current washing of the concentrated bubbly-zone of a single stage REFLUXTM Flotation Cell', MINERALS ENGINEERING, 206 (2024) [C1]

|

Open Research Newcastle | |||||||||

| 2024 |

Iveson SM, Boonzaier N, Galvin KP, 'Beneficiation of High-Density Tantalum Ore in the REFLUX™ Concentrating Classifier Analysed Using Batch Fractionation Assay and Density Data', MINERALS, 14 (2024) [C1]

A laboratory-scale REFLUX¿ Concentrating Classifier was operated in continuous mode to beneficiate a sub 0.100 mm tantalum ore with a head grade of 0.56 wt.% Ta. The un... [more] A laboratory-scale REFLUX¿ Concentrating Classifier was operated in continuous mode to beneficiate a sub 0.100 mm tantalum ore with a head grade of 0.56 wt.% Ta. The unit incorporated a lower section with a reduced diameter to accommodate a low yield. At a yield to underflow product of 4.0 wt.%, a product grade of 13.3 wt.% was achieved (23.7 upgrade) at a recovery of 88.3%. Samples of the feed, product and reject were then fractionated in a batch REFLUX¿ Classifier unit using dense lithium heteropolytungstate (LST) solution into 11 fractions. Each of these fractions was then screened into seven size intervals and analysed by pycnometry and X-ray fluorescence (XRF). Most of the material was found to reside in four relatively narrow density bands. A new analysis based on the recovery of selected tracer elements showed that the partition curve had good closure at both ends and that the density cut point and Ep both increased with decreasing particle size. For the +0.045 mm material, the density cut point was estimated to be around 3952 kg/m3 with an Ep of 317 kg/m3, but it was expected that this new method could overestimate Ep. An alternative novel approach for estimating the partition performance was developed. This method estimated the cut point and Ep values to be 3764 kg/m3 and 107 kg/m3, respectively. However, sensitivity analysis found that due to the near total absence of material in the density range from 3400 kg/m3 to 4700 kg/m3, the Ep could likely lie anywhere in the range from 0 to 250 kg/m3. The methodology proved useful in establishing these limitations in the analysis.

|

Open Research Newcastle | |||||||||

| 2024 |

Wang P, Yvon M, Parkes S, Galvin KP, 'Improving flotation hydrodynamics to maximize nickel recovery from tailings', MINERALS ENGINEERING, 216 (2024) [C1]

The REFLUX¿ Flotation Cell (RFC¿) was used to investigate the flotation of a nickel tailings stream containing significant levels of dissolved solids, slow floating nic... [more] The REFLUX¿ Flotation Cell (RFC¿) was used to investigate the flotation of a nickel tailings stream containing significant levels of dissolved solids, slow floating nickel minerals, and ultrafine hydrophilic silicates. Slow floating minerals are known to lead to excessive gangue entrainment and low upgrade. The performance of the RFC¿ was investigated with reference to that observed for a batch mechanical cell. The flotation feed system displayed complexity including sensitivity to aging of the tailings, coupled with acute sensitivity to the effects of dilution. The work suggests dilution of the tailings feed leads to the dissolution of surface species formed during aging, essential for hydrophobicity and indeed nickel recovery. These observations point to the need for new work on the interplay between the water chemistry and the mineral surfaces. Although the nickel recovery was only of order 30 %, the recovery of the hydrophobic components from a single stage RFC¿ was closer to 80 %. Moreover, the silica content of the feed was reduced from 37 % to ~1 % through a powerful counter-current washing of the rising bubbles, delivering a hydrophobic-hydrophilic selectivity exceeding ~10. The product flux, measured relative to that achieved using a mechanical cell at the same feed concentration, was more than 6-fold. This work demonstrated the efficacy of the RFC¿ hydrodynamics in upgrading slow floating minerals using a reduced footprint while rejecting the hydrophilic ultrafine particles.

|

Open Research Newcastle | |||||||||

| 2023 |

Starrett JB, Galvin KP, 'Application of inclined channels in the hydrodynamic classification of minerals by particle size', MINERALS ENGINEERING, 195 (2023) [C1]

This study utilised a REFLUX¿ Classifier, with water as the fluidising medium, to classify feed suspensions based on particle size. This work built on an earlier approa... [more] This study utilised a REFLUX¿ Classifier, with water as the fluidising medium, to classify feed suspensions based on particle size. This work built on an earlier approach, known as Split Fluidisation, to achieve sharp separations, focussing on the potential to control the separation size, and to deliver efficient separations at high throughputs. The partition curves were remarkably sharp, with the Imperfection, I = Ep/D50, typically less than 0.14 for separation sizes covering a range from 182 µm down to 44 µm, with virtually no ultrafine entrainment with the coarse underflow, and virtually no oversize particles misplaced in the overflow. The solids throughputs ranged from 39 t/m2/h down to 8 t/m2/h. Importantly, the study achieved a deeper understanding of how to control the separation size, with the fluidisation velocity identified as the key control variable. The underflow rate is then increased to a level sufficient to prevent the bed level from rising, while ensuring the solids throughput is below the limit applicable for a given separation size.

|

Open Research Newcastle | |||||||||

| 2023 |

Crompton LJ, Islam MT, Galvin KP, 'Assessment of the partitioning of coarse hydrophobic particles in the product concentrate of the CoarseAIR™ flotation system using a novel mechanical cell reference method', MINERALS ENGINEERING, 198 (2023) [C1]

|

Open Research Newcastle | |||||||||

| 2023 |

Rodrigues AFDV, Delboni Junior H, Rodrigues OMS, Zhou J, Galvin KP, 'Gravity separation of fine itabirite iron ore using the Reflux Classifier-Part I-Investigation of continuous steady state separations across a wide range of parameters', MINERALS ENGINEERING, 201 (2023) [C1]

High grade iron ore resources are becoming depleted in Brazil, with relatively low-grade ores requiring more intensive concentration to achieve a premium product. Accor... [more] High grade iron ore resources are becoming depleted in Brazil, with relatively low-grade ores requiring more intensive concentration to achieve a premium product. Accordingly, a typical industrial itabirite concentration circuit includes desliming in hydrocyclones and concentration via reverse flotation, product thickening and filtration, with the slimes sent to tailings thickeners, and onto tailings storage facilities. This work examined the potential for applying a vastly simpler approach, a single stage of gravity separation using the Reflux Classifier. Here the classified feed, 90 % finer than 0.150 mm, is sent directly to the Reflux Classifier, leading immediately to a high-grade concentrate at high solids concentration. Part I describes the findings from a comprehensive series of experiments covering the effects of bed density set point, feed pulp density, throughput, fluidisation water rate and lamella channel spacing. The main program, based on an ore with 8 % goethite and 45 % hematite, achieved a feed upgrade from 37 % to 65.6+/-0.4 % iron and iron recovery of 72.9+/-0.4 % at 9 t/m2/h. A second feed with 1 % goethite and 57 % hematite was upgraded from 41 % to 66.3+/-0.4 % iron at an iron recovery of 84.7+/-0.5 % at 10 t/m2/h. (The grade of pure hematite is 69.9 % iron). It was essential to run the Reflux Classifier at a sufficient volumetric rate to achieve shear induced inertial lift of the coarse silica within the closely spaced inclined channels, to reject the gangue minerals from the high-grade product. The results demonstrate the technical feasibility of applying the Reflux Classifier to upgrade itabirite feeds.

|

Open Research Newcastle | |||||||||

| 2023 |

Shi P, Tholan V, Sommer A-E, Heitkam S, Eckert K, Galvin K, Rzehak R, 'Forces on a nearly spherical bubble rising in an inclined channel flow', INTERNATIONAL JOURNAL OF MULTIPHASE FLOW, 169 (2023) [C1]

The dynamics of a sub-millimeter air bubble rising at a bubble Reynolds number of about 100 in water in an inclined, laminar channel flow is investigated experimentally... [more] The dynamics of a sub-millimeter air bubble rising at a bubble Reynolds number of about 100 in water in an inclined, laminar channel flow is investigated experimentally. In this configuration which is relevant in modern separation technologies for valuable particles, the bubble is undergoing a cross-stream motion, as the buoyancy force is not aligned with the undisturbed liquid flow. From measurements of bubble velocities and trajectories we estimate the drag and lift forces on the bubble at two different channel Reynolds numbers. The results are compared with their streamwise counterparts, i.e. in the configuration where the bubble rises largely along a streamline of the undisturbed liquid flow. For the lower channel Reynolds number, the cross-stream effects are only small. For the larger channel Reynolds number however, the drag coefficient is found to be notably larger than its streamwise counterpart. The lift coefficient may be either larger or smaller than its streamwise counterpart depending on the detailed local flow conditions. In particular, its value is non-zero when the bubble crosses the channel centerline where the shear rate is zero. These deviations are found to be closely connected with the bending of the bubble wake as well as the finite value of the angle formed between the bubble slip velocity and the velocity of the liquid flow.

|

Open Research Newcastle | |||||||||

| 2023 |

Parkes S, Wang P, Galvin KP, 'Revisiting a flotation cell benchmark', MINERALS ENGINEERING, 200 (2023) [C1]

|

Open Research Newcastle | |||||||||

| 2023 |

Rodrigues AFDV, Delboni Jr H, Silva K, Zhou J, Galvin KP, Filippov LO, 'Transforming iron ore processing-Simplifying the comminution and replacing reverse flotation with magnetic and gravity separation', MINERALS ENGINEERING, 199 (2023) [C1]

|

Open Research Newcastle | |||||||||

| 2022 |