University-made Printed Solar powers Coldplay concerts

Printed Solar, a 100% recyclable solar material developed by researchers at the University of Newcastle, is helping power Coldplay’s Music of the Spheres world tour thanks to a collaboration between the iconic band, Kardinia Energy (the technology's commercialisation partner), and the University’s Centre for Organic Electronics (COE).

Coldplay has made significant commitments to sustainability, continuously exploring and applying new technologies to reduce their environmental impact. This partnership is another step towards achieving their ambitious sustainability goals to reduce their tour’s carbon emissions by 50%.

An array of 500 square meters (about twice the area of a tennis court) of Printed Solar is placed behind the seats behind the stage and elsewhere in the venue to collect power in battery packs. These batteries are then used to power Coldplay’s C Stage and fulfil other ancillary power needs throughout the venue.

Printed Solar uses organic photovoltaics (OPVs) which are a next-generation solar cell technology that uses organic compounds to convert sunlight into electricity. Now producing at scale with the support of the Newcastle Australian National Fabrication Facility (ANFF) Hub, located at the Newcastle Institute for Energy and Resources (NIER) at the University of Newcastle. Manufactured with PET plastic using roll-to-roll printing techniques and fully recycled in-house, Printed Solar is one of the lowest emission-intensive energy sources available.

Dr Ben Vaughan, Hub Manager for the ANFF, says Printed Solar has enormous potential for a variety of applications.

“Right now, we are helping to support one of the world's largest rock bands to run their shows. It's a pretty exciting and unusual development for us, but there are lots and lots of applications where this can have a genuine impact on the energy generation for the world,” said Dr Vaughan.

“We see this as being applied to many, many places, industrial, rooftops, emergency situations, because it's so lightweight and flexible and print on demand.”

Members of TRaCE, NIER, COE and Kardinia Energy backstage at Accor Stadium.

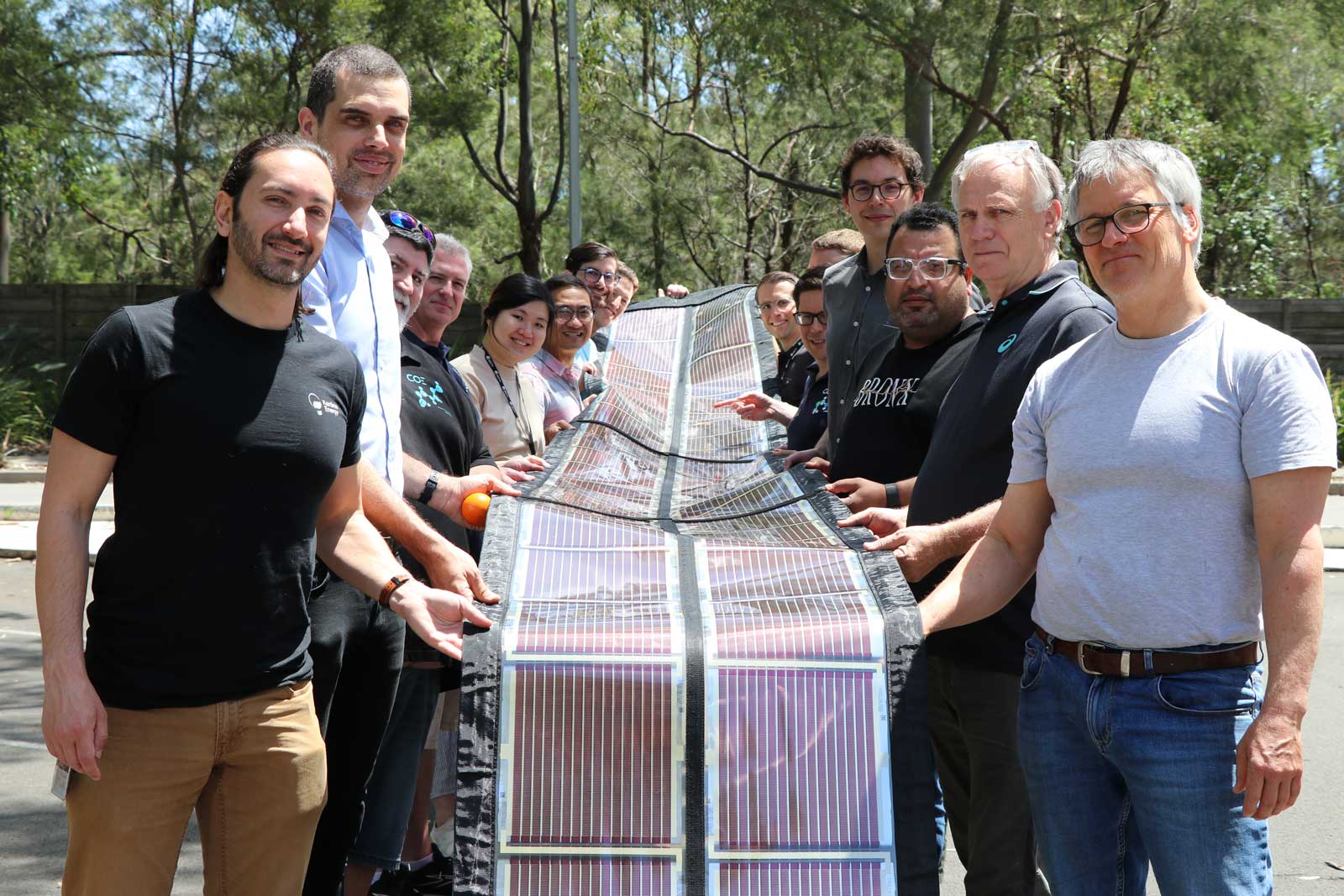

The COE team in Newcastle holding up a roll of Printed Solar designed for the Coldplay concert.

Dr Michael Dickinson, a University of Newcastle COE researcher, described the experience of seeing Printed Solar at a concert as once-in-a-lifetime.

“I don't think anyone on the team ever thought that our centre would get connected to Coldplay,” said Dr Dickinson.

“We had to figure out how to mount our solar cells to seats, which, to be honest, none of us had ever even thought about. The seats are covered in mesh for every performance. We used the mesh itself as a fixing point and we anchored them down in long strips and directing them still towards the sun.”

“I can say for everybody in the team that for us to get this out in the field and actually get results that we can be proud of has been the most amazing experience of a lifetime.”

Professor Zee Upton, Deputy Vice-Chancellor (Research and Innovation) at the University of Newcastle, said the Printed Solar panels are the latest example of home-grown innovations with impact at national and international levels.

“This is such an exciting development and a testament to the calibre of research the University of Newcastle is delivering,” Professor Upton said.

“This unique collaboration reaffirms our commitment to next generation resources and delivering new energy technologies that bring us closer to a more sustainable future.”

The team has joined Coldplay from across Europe to Australia and New Zealand, with plans to continue deploying the technology globally in 2025.

History of Printed Solar

Printed Solar has come a long way since Professor Paul Dastoor began researching conducting polymers in 1996.

His team at the Centre for Organic Electronics has been manufacturing the technology on-site at the University of Newcastle since 2012, supported by the ANFF.

In 2020, Professor Dastoor partnered with Kardinia Energy’s CEO Anthony Letmon to commercialise the technology.

“I've been working on this for almost 20 years and when I started, the solar cells we were making were the size of my pinky fingernail, and now we're installing hundreds of square metres in a stadium with one of the world's largest bands,” said Dr Ben Vaughan.

“To see that installation in situ and it's having some impact on their show has been incredibly rewarding and I know our whole team has been very excited to do this project and it's been a real culmination of many years of effort.”

Fast-tracking the technology to market

With support from the Trailblazer for Recycling and Clean Energy (TRaCE) program, the University of Newcastle and ANFF researchers, Kardinia Energy plans to develop an Australian-based manufacturing facility to fast-track the technology to market.

They are also working on a TRaCE R&D Voucher Project to develop their own Balance Of System optimised for converting energy from Printed Solar and silicon PV to various outputs, continuing to enhance Printed Solar’s performance.

Sam Clifton, Kardinia Energy Head of Operations, holding a battery pack charged by Printed Solar at Accor Stadium.

Professor Paul Dastoor, inventor of printed solar at the University of Newcastle, noted the importance of these projects.

“At the moment we are manufacturing all of the printed solar here in our research facility at NIER at the University of Newcastle, which allows us to do many hundreds to thousands of metres of material at a time,” said Professor Dastoor.

"With Kardinia Energy, the next step is to develop a full manufacturing facility through a TRaCE project, which will be right here in the Hunter Valley. That's when we can really transition this technology out of the laboratory and into industry.”

“The additional TRaCE R&D Voucher project will help us maximise our power output for more deployments, whether for concert stages, charging electric vehicles, or industrial applications.”

Contact

- Annalese Thomas

- Email: annalese.thomas@newcastle.edu.au

Related news

- Scientists find a fast, new way to recover high-grade silver from end-of-life solar panels

- University of Newcastle appoints new Executive Director of Newcastle Institute for Energy and Resources (NIER)

- From early ideas to enterprise insights

- Beauty without barriers

- Building Partnerships and Biodiversity in the Cook Islands

The University of Newcastle acknowledges the traditional custodians of the lands within our footprint areas: Awabakal, Darkinjung, Biripai, Worimi, Wonnarua, and Eora Nations. We also pay respect to the wisdom of our Elders past and present.