Global Innovative CentreAdvanced Nanomaterials

Discoveries and patents

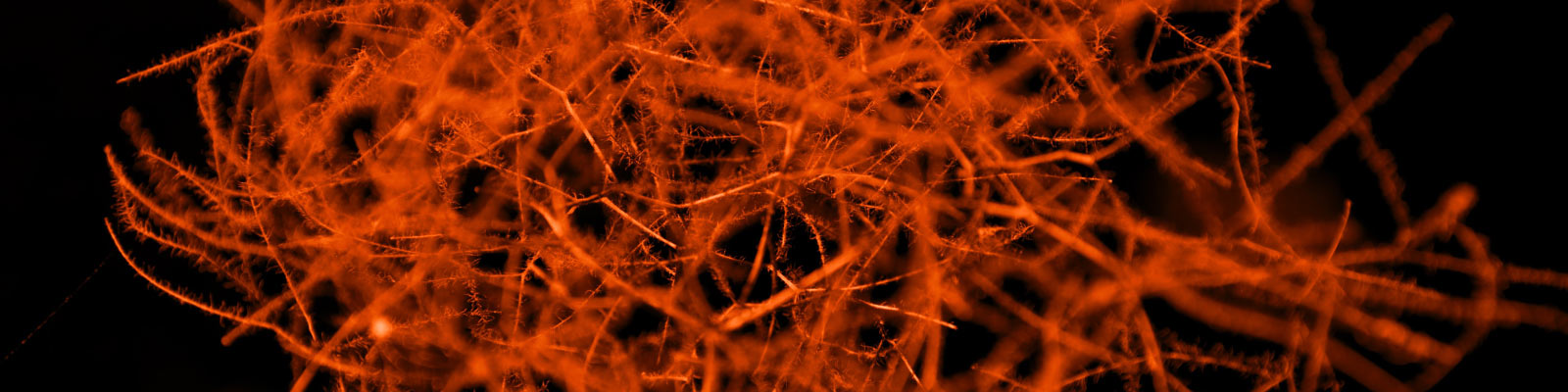

Mesoporous carbon nitride (MCN) materials with tunable pore structures and textural parameters

(JP Patent Appl. No. 2004-316596)

Application: CO2 capture and conversion

- Professor Vinu has introduced a general strategy to prepare highly ordered hexagonal mesoporous carbon nitride (MCN) materials, designated as MCN-1, with a uniform pore size distribution using a simple polymerisation reaction between ethylenediamine and carbon tetrachloride using a nano hard-templating method (Adv. Mater. 2005, 17, 1648; Angew Chem. 2009, 48, 7884; Angew. Chem. 2010, 49, 5961-5965; JP Patent 2004-316596).

- This is the first report of ordered nanoporous nitrides and has created a new field in porous materials research.

- One of the important features of the materials is that they have both inbuilt basic sites in the form of NH2 or NH groups and a semiconducting framework structure with ordered pores. These properties make them exciting candidates to capture and convert CO2 molecules into value-added products with the help of sunlight and water.

- Other researchers have realised the importance of the field and this new material, and recently, many leading researchers including Professor Kazunari Domen (The University of Tokyo), Professor Mietek Jaroniec (Kent State University), and Professor Dongyuan Zhao (Fudan University) have started to work on applications of these materials for hydrogen evolution, basic catalysis, energy storage and conversion.

- View more information on the patent.

Novel class of nanoporous carbon materials

JP patent Appl. No. 2005-022234, JP Patent Appl. No. 2009-021407

Application: Material can be used as electrodes for fuel cells and supercapacitors

- Professor Vinu has developed a novel class of nanoporous carbon materials including carbon nanocage, and nanocoops, hexagonal and cubic nanoporous carbons with different textural parameters.

- He has successfully synthesised novel nanoporous carbon nanocage (CNC) materials with a very high surface area of more than 1600m2/g and pore volume of 2.2 cm3/g for the first time using a nanotemplating technique via the 'controlled pore filling method' which he developed.

- This material was selected as the ‘NIMS Material of the Year' 2006 and one of the 50 most attractive materials from Japan (JACS 2008, 129, 11022; JP patent 2005-022234; J. Mater. Chem. 2005, 15, 5122).

- The materials show very high adsorption capacity for proteins, amino acids, DNA and organic dyes.

- Professor Vinu has demonstrated the importance of pore engineering in CNC design. He achieved a very high selectivity for adsorption of tea components (catechin and tannic acid) through a simple one-pot process using CNC materials (JACS 2008, 129, 11022).

- These discoveries attracted interest from industries in Japan (Taiyo Kagaku and Kurita Water Industries) who have started to collaborate with our group and signed a non-disclosure agreement with NIMS for the use of the materials.

- Professor Vinu also discovered the first nanoporous fullerene material with highly ordered porous structure and high surface area.

- One of the exciting features of the material is its very high conductivity (in the range of 25 to 250S/cm).

- Professor Vinu designed a specific synthesis protocol to prepare these exciting materials by combining the solution chemistry of fullerene with the nanotemplating pathway which can control the conductivity with a simple adjustment of the framework structure of the nanoporous fullerene (JP Patent 2009-021407).

- Electrochemical studies have shown that this material is a good candidate as an electrode for fuel cells and supercapacitors.

Hydrogen

Application:

- Generating and storing hydrogen in commercial hydrogen plants

- Utilising hydrogen fuel cells to generate clean energy

- Utilising hydrogen to produce fine chemicals and ammonia fertiliser

- The GICAN team is designing and developing an advanced materials platform using naturally available resources to generate, store and utilise hydrogen.

- In particular, we are actively working on designing carbon-based thermo, electro and photocatalytic nanostructures to generate clean hydrogen with the help of visible sunlight and electricity generated from the solar cells.

- We are also carrying out extensive research on the theoretical understanding of the interaction and the diffusion of hydrogen gas in the developed nanostructures using density functional theory.

- The team is developing new nanosorbents derived from biomass and natural nanoclays for storing hydrogen generated through sunlight and solar cells.

- We have a dedicated research group that is focusing on the utilisation of hydrogen for clean energy generation (fuel cells) and the production of fine chemicals and ammonia fertilizers.

- We are working with our industry partners to translate some of these hydrogen generation and storage technologies into commercial hydrogen plants.

CO2 capture and conversion

Application: Capturing CO2 emissions and converting them into commercially viable products and technologies

- The GICAN team is designing and developing advanced materials from natural clay-based halloysites and other carbon based nanostructures for carbon capture.

- We use a unique nanotechnological approach to design nanoporous carbon-based adsorbents with extremely high surface area, tunable surface charges and basic components.

- A bulk production facility to fabricate these nanostructures in tonnes of quantity has been established at the Newcastle Institute for Energy and Resources (NIER).

- We plan to install a large-scale CO2 capture plant at NIER in collaboration with the industry partners including Minotaur, Nature Nanotech and Andromeda.

- We are also actively working on converting the adsorbed CO2 into value-added products through thermocatalytic, biocatalytic, microbial, and photocatalytic approaches.

- We have been actively working with several industry partners including SABIC and Nature Nanotech on the conversion of CO2 into value-added products and the conversion of our lab-scale research into commercially viable technology.

The University of Newcastle acknowledges the traditional custodians of the lands within our footprint areas: Awabakal, Darkinjung, Biripai, Worimi, Wonnarua, and Eora Nations. We also pay respect to the wisdom of our Elders past and present.