Centre for Geotechnical Science and Engineering

Rock Mechanics Laboratory And Capabilities

SPECIALISED EQUIPMENT

- Surface grinder – used for ensuring flat and parallel ends required for undertaking uniaxial or triaxial testing on core specimens.

- Large Scale Shear Box - 720mm x 720mm shear box with 300 tonne normal capacity and 200 tonne shear capacity; the high capacity shear box is suitable for testing rock fill or mine waste rock under high stresses.

- High Stress Triaxial Testing System – manufactured by GDS Instruments with a thick walled stainless steel cell. Confining stress up to 64MPa can be achieved with axial loads up to 250 kN allowing for testing of samples for 38 mm to 100 mm in diameter. The same triaxial load frame can be used with a 300 mm cell which allows for testing of course materials such as mine spoil.

- 180 tonne compression machine – Tinius Olsen compression machine allowing compression forces up to 1800 kN.

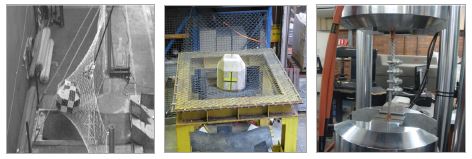

Figure 1: Large Scale Shear Box, High Stress Cell and Large Scale Triaxial Cell

ROCK TESTING CAPABILITIES

- Rock porosity, density and permeabilit;

- Sample coring and trimming and surface grinding;

- Unconfined compression testing;

- Sonic velocity (S and P wave);

- Poisson’s Ratio;

- Indirect Tensile Testing (Brazilian Test);

- Point Load Testing;

- Triaxial Testing of rock core and rock fills (300 mm cell);

- Direct shear testing of rock joints, discontinuities and rock fills, including residual shear by repeated shearing;

- Schmidt Hammer testing of rock masses;

- Rock Joint Roughness by 3D scanning.

ROCKFALL BARRIER ASSESSMENT - SPECIALISED EQUIPMENT

- 2.5 x 2.5 m steel frame for testing of steel mesh panels.

- 700 mm thick heavily reinforced concrete strong floor.

- Load cells for the measurement of forces in steel cables and at the foot of steel posts.

- 1000 kN MTS testing machine for tensile, compressive, dynamic and cyclic testing of barrier components.

- 3 axes accelerometers.

- High speed cameras with variable frame rate (from 100 to 8000 frames per second).

- Motion analysis software for the measurement of position, velocity and acceleration during impact.

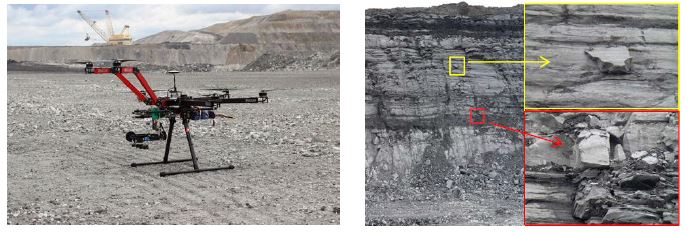

Figure 2: Full scale rockfall barrier test, Steel frame mesh paneling, Tensile testing of barrier components

ROCK FALL BARRIER TESTING CAPABILITIES

- Full scale barrier testing: in accordance to EOTA specifications, a barrier made of 3 panels (max. 15 m overall) can be tested, with load cell acquisition and high speed camera recording.

- Testing of steel mesh panels: the tests are performed by vertical impact of a concrete block, shaped according to EOTA specifications. The dropping height can be adjusted in order to reach the required impact energy.

- EOTA Standard Tests rocks for 60 kg o 660 kg.

- Tensile testing of components – steel wire ropes, cables connected by clamps, single wires and portions of mesh panels.

ROCK FALL AND SLOPE HAZARD ASSESSMENT MODELLING - SPECIALISED EQUIPMENT

- UAV hexacopter with two forward facing arms, bent for a clear field of view. Features include 2-axis gimbal for DSLR camera, FPV camera and laser module.

- UAV Quadcopter - DJI Phantom 1 with 12MP GoPro 3.

- UAV Quadcopter - DJI Phantom 3 Professional with integrated 12MP camera and 3-axis gimbal.

- Fix Laser scanner - Leica C10 with a range of 300m.

- SfM software for image processing.

Figure 3: Hexacopter and Rock fall hazard images

ROCK FALL SLOPE MEASUREMENT AND MODELLING CAPABILITIES

- Aerial and ground-based laser scanning and photography techniques to produce high quality detailed 3 dimensional surface models of slopes and high walls.

- Stability analysis and rock fall modelling using these 3D models.

For further information regarding testing capabilities and rates please contact:

CONTACT

Lachlan Bates

Business Manager

Geotechnical Science & Engineering

Discipline Civil, Surveying & Environmental Engineering

University of Newcastle

T: +61 2 4921 8978

M: + 408 292 638

The University of Newcastle acknowledges the traditional custodians of the lands within our footprint areas: Awabakal, Darkinjung, Biripai, Worimi, Wonnarua, and Eora Nations. We also pay respect to the wisdom of our Elders past and present.