Researcher Highlights

Why Plasma Matters

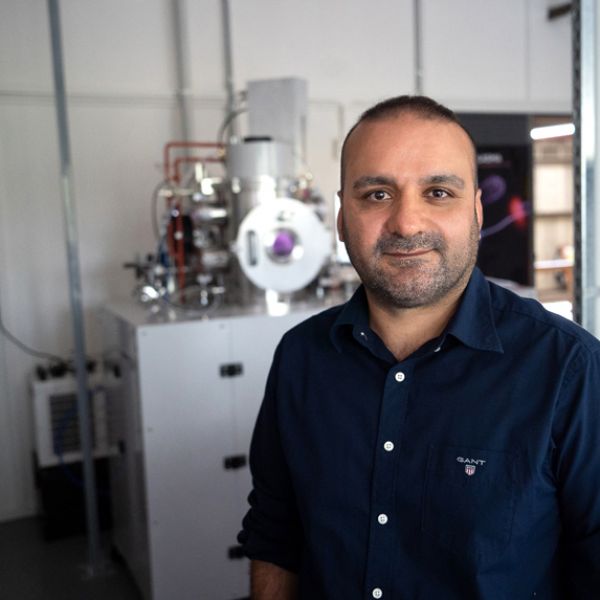

Dr Behnam Akhavan is taking a range of biomedical and environmental problems and addressing them with a novel solution – plasma surface engineering.

A surface engineer, Dr Behnam Akhavan has relocated to the University of Newcastle to set up his Plasma Bio-Engineering Lab to push the boundaries of biomedical engineering and deliver innovative solutions to grand challenges in medicine, water purification and the environment.

“I’ve come here to establish and lead a unique plasma lab in close collaborations with industry partners across a wide range of domains – from biomedicine to sustainability,” Behnam says.

Harnessing the power of plasma (ionised gas), Behnam’s lab develops technologies that can be used for biomechanical bone implants, multifunctional nanoparticles for targeted drug delivery and cancer therapy, highly efficient absorbents for cleaning water, and smart coatings for windows to save energy.

One wicked problem that Behnam is looking to address is the issue of rejection in medical implants. Every time a patient receives a surgical implant - whether it be a dental implant, a knee replacement, a stent, or an artificial nerve conduit, a gamble is involved; will the body accept or reject the new object? Behnam uses plasma to cover the implant with a more body-friendly coating to hide the device and trick the body to think it is friendly.

“The plasma coating almost serves as an invisibility cloak to protect the implant from detection, infection, and rejection,” Behnam says. These plasma-coated implants hold great promise to benefit the rapidly growing number of patients suffering from afflictions such as bone fracture, osteoporosis, and bone cancer.

“The plasma-coating is substrate-independent; it means that it enables the surface-engineering of virtually any implant of choice, regardless of their shape and chemical composition,” Behnam adds. “Excitingly, the plasma process generates negligible waste, so it also offers tremendous environmental benefits.”

Creating Solutions to Shortages

In response to the shortage of indium (the crucial rare mineral that makes touch screens optically transparent and electrically conductive), Behnam turned his eye to developing a new form of plasma coating using a technique called ‘magnetron sputtering’. This creates an ultra-thin structure that’s less than 100 nanometres thick which is around one-thousandth of the width of a human hair.

The process only takes a few minutes, is cheaper than using indium and can be used for an array of glass surfaces such as touch-screens. Not only is it a cheaper option, it’s more environmentally sustainable and readily scalable for commercial implementation. Behnam believes the scope for plasma-based technologies is almost limitless, and is excited about the opportunities it holds.

Collaboration the Key to Success

For Behnam, pushing the boundaries of biomedical engineering is not possible without engaging in national and international collaborative research; and his Plasma Bio-engineering Lab presents tremendous opportunities for such collaborations.

“For me, collaboration has been a big part of my research journey so far, and I have continuously collaborated with partners both within and outside my field, such as chemists, biologists, and surgeons,” Behnam says. “I’m currently working with leading laboratories in the fields of biomaterials and biotechnology across Europe, the USA, China and New Zealand.”

These include collaborations with Tufts University in the US, three groups at the University Medical Centre Utrecht in the Netherlands and at Southwest Jiaotong University China – utilising novel plasma technologies to develop better health outcomes.

“In a collaboration with the University of Otago in New Zealand, for example, we are developing a new generation of solid-hydrogel hybrid implants with controlled delivery of growth factors using plasma technologies for enhanced bone regeneration and vascularisation,” Behnam adds.

When it comes to collaboration, Behnam looks far afield, and also closer-to-home. Upon commencing work at the University of Newcastle, Behnam set about becoming an affiliate of the Hunter Medical Research Institute (HMRI) where he plans on working within the newly-formed Precision Medicine Research Program.

Behnam always has an eye toward collaboration and opportunity.

Industry Engagement

To make translational impact, Behnam believes engagement with industry partners and end-users should be central to any academic role and not just as an add-on responsibility. “Plasma technologies are particularly attractive for application in biomedical industry; because they are clean, environmentally friendly, and super easy to scale up,” Behnam adds. “The research direction of Plasma BioEngineering Lab is well-aligned with the translation of new technologies to biomedical manufacturing companies.”

Collegial and collaborative, Behnam has big plans at the University. “I plan to build a strong network of alliances with established, mid- and early-career researchers across the colleges, research institutes and centres at the University,” Behnam says. “I’m also particularly excited to contribute to shaping our new program of Medical Engineering to train our next generation of biomedical engineers.”

Passionate about developing engineering solutions to solve societal problems, Behnam is inspired to build on his work locally and globally. “Nothing is more rewarding for me than contributing to the development of science and technologies that address the needs of our society and improve health outcomes.”

The University of Newcastle acknowledges the traditional custodians of the lands within our footprint areas: Awabakal, Darkinjung, Biripai, Worimi, Wonnarua, and Eora Nations. We also pay respect to the wisdom of our Elders past and present.