Solving real-world problems through new materials

What a difference materials science makes. By designing and discovering new matter and making it into real products, the experts in this field are opening up new possibilities.

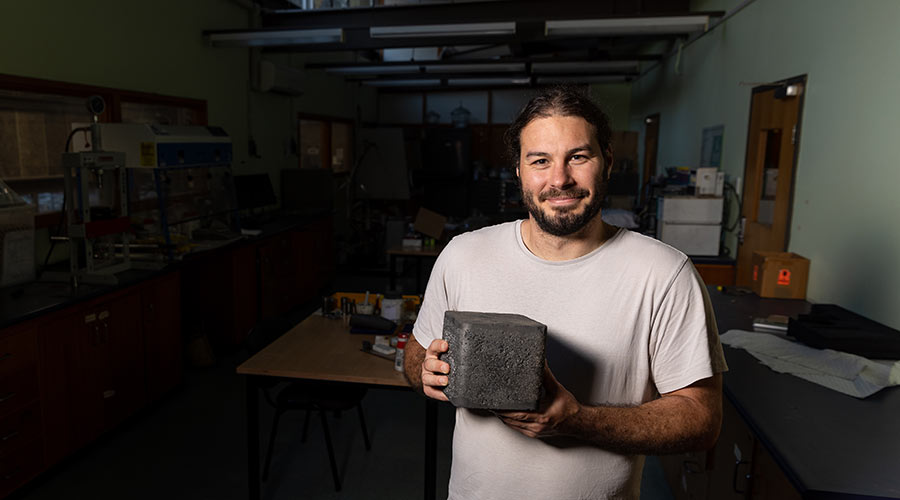

Dr Dylan Cuskelly is one of these material conceptualising minds. Something he and his team co-researchers balance while teaching students day to day.

Material science has been a passion of Dylan’s since childhood. He always loved making things in a laboratory and found it the most interesting part.

After being involved in a small research project as an undergraduate, he did his honours project in the field and then his PhD. These were both in mechanical engineering with a focus on the synthesis of novel materials – and completed at the University of Newcastle.

“Through my early work, I investigated advanced ceramics known as MAX phases, discovering previously unknown phases and developing new synthesis processes,” says Dylan.

“This work remains active today and has expanded into the emerging group of MAB phases where the discovery of new phases of any reaction pathways are being explored.”

The advanced materials challenge

Currently, Dylan’s main research challenge is creating new metal alloys and compounds to solve current and future problems.

“Advanced engineering applications are often limited by the materials that are available being pushed into ever more hostile conditions. We create new materials that can thrive in those conditions and applications.”

Dylan’s challenge as a researcher is not only making advanced materials but doing so in economical ways.

“Many really cool materials exist out there with amazing properties. However, they are too expensive to implement,” he says.

Sometimes this is because they involve expensive elements, and sometimes it’s because the synthesis process is just too complex.

“My work investigates the synthesis process to simplify it and attempts to make these advanced materials economic to produce.”

Energy storage tech and sustainability

While he loves to do science for the sake of science itself, the applications of his work are of great value.

One of the key areas Dylan is looking at while working in the Advanced Materials group at Newcastle, alongside Dr Heber Sugo and Prof Erich Kisi, is developing a new call of metal alloys that can be used for storing thermal energy.

Energy storage is needed to help intermittent renewable solutions, such as solar and wind take over. However, the storage and containment of that energy can present a materials problem.

“To solve it, I make new metal alloys capable of storing energy as heat to help pave the way for a renewable energy future,” says Dylan.

They called these materials MGAs, and after many years of fundamental research investigating their low-risk, high storage capacity, the materials have emerged as commercially viable energy storage media.

The technology has now been commercialised through MGA Thermal – a start-up company founded by the team.

Not only has the company made a new product for storing renewable energy that has engaged customers internationally, but the materials are also being manufactured in the local region.

This is helping to bring advanced manufacturing back to the Hunter, boosting the economy and creating sustainable and high-paying jobs.

Collaborations make it real

Despite loving the laboratory, Dylan works in a much broader context.

To help translate his research into actual impact, he’s had to build and grow various partnerships and collaborations.

“I work with everyone from other researchers to tradespeople, investors, start-ups and businesses in order to understand the whole value chain from an idea, through to research, to the creation of a material, then a product and into a reality that makes a difference to people’s lives,” says Dylan.

If you’re not finding a solution to a real problem, what’s the benefit?

To date, he’s managed to secure three grants and over $224,363 in funding. These have come from Google Australia iSTEM Zero to Hero, the University of Melbourne and MGA Thermal Pty Ltd.

From metals research to STEM education

Alongside being heavily magnetised towards materials science research, Dylan’s other passion is for education, specifically the engaging teaching of engineering and STEM concepts at a university level.

“I have developed and delivered a new engineering practical course and am perpetually working on other courses to improve the ways in which we can best deliver content to help students learn,” he says.

Together his combined interests and work are making a material difference to the future – bringing energy into research, learning and the world.

Solving real-world problems through new materials

One of the key areas Dylan is looking at while working in the Advanced Materials group at Newcastle, alongside Dr Heber Sugo and Prof Erich Kisi, is developing a new call of metal alloys that can be used for storing thermal energy.

Career Summary

Biography

I completed my undergraduate and postgraduate degrees at the University of Newcastle in Mechanical Engineering with a focus on the synthesis of novel materials. Through my early work, I investigated advanced ceramics known as MAX phases, discovering previously unknown phases and developing new synthesis processes. This work remains active today and has expanded into the emerging group of MAB phases where the discovery of new phases any reaction pathways are being explored.

While working in the Advanced Materials group at Newcastle, Dr Heber Sugo, Prof Erich Kisi and I developed a new call of metal alloys that can be used for storing thermal energy. We called these materials MGAs and after many years of fundamental research investigating their low-risk high storage capacity, these materials have emerged as commercially viable energy storage media. This has lead to the commercialisation of the technology through the founding of the company MGA Thermal which I am a director. This has given me a rare experience to see a technology move from conceptual all the way through the research phase into commercial applications.

My other passion is Education - specifically engaging teaching of engineering and STEM concepts at a university level. I have designed developed and deliver a new engineering practice course and am perpetually working on other courses to improve the ways in which we can best deliver content to help students learn.

Qualifications

- Doctor of Philosophy, University of Newcastle

- Bachelor of Engineering (Mechanical) (Hons), University of Newcastle

Keywords

- Energy Storage

- Materials Science

- Mechanical Engineering

- STEM Education

- Technical Ceramics

- engineering

Languages

- English (Mother)

Fields of Research

| Code | Description | Percentage |

|---|---|---|

| 401601 | Ceramics | 60 |

| 401607 | Metals and alloy materials | 40 |

Professional Experience

UON Appointment

| Title | Organisation / Department |

|---|---|

| Lecturer | University of Newcastle School of Engineering Australia |

Professional appointment

| Dates | Title | Organisation / Department |

|---|---|---|

| 1/4/2019 - 2/4/2021 |

Founder and Director I Co-founded and grew the company from a small startup into a successful international business leading the world in renewable energy storage and materials science advanment. |

MGA Thermal Pty Ltd |

Awards

Teaching Award

| Year | Award |

|---|---|

| 2017 |

Excellence in Teaching and Learning University of Newcastle |

Publications

For publications that are currently unpublished or in-press, details are shown in italics.

Chapter (1 outputs)

| Year | Citation | Altmetrics | Link | |||||

|---|---|---|---|---|---|---|---|---|

| 2018 |

Kisi E, Sugo H, Cuskelly D, Fiedler T, Rawson A, Post A, Bradley J, Copus M, Reed S, 'Miscibility Gap Alloys: A New Thermal Energy Storage Solution', 523-532 (2018) [B1]

|

Open Research Newcastle | ||||||

Conference (6 outputs)

| Year | Citation | Altmetrics | Link | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2021 |

Reilly W, Gregg A, Cuskelly D, McBride W, '‘Optimised Blackboard’; How first year students created their own pseudo-LMS', Proceedings of the 32nd Annual Conference of the Australasian Association for Engineering Education (AAEE 2021) (2021) [E1]

|

Open Research Newcastle | |||||||||

| 2019 |

Tegg L, Cuskelly D, Keast VJ, 'Synthesis and Plasmon Responses of Sodium Tungsten Bronze Nanoparticles', International Conference on Metamaterials Photonic Crystals and Plasmonics, 1396-1397 (2019)

The sodium tungsten bronzes are sub-stoichiometric metal oxides with interesting electrical and optical properties which vary with the sodium content. We have developed... [more] The sodium tungsten bronzes are sub-stoichiometric metal oxides with interesting electrical and optical properties which vary with the sodium content. We have developed a synthesis technique which makes high-purity sodium tungsten bronze nanoparticles across a wide composition range. Results from electron energy-loss spectroscopy reveal that these materials support high-quality localised surface plasmons, with resonance frequencies which are tunable across visible and near-infrared frequencies by varying the sodium content.

|

||||||||||

| 2019 |

Copus M, Fraser B, Cuskelly D, Reed S, Post A, Kisi E, 'Unifying capture, storage and discharge of thermal energy using miscibility gap alloys', Proceedings of the 24th SolarPACES International Conference (SolarPACES 2018), 2126, 200012-1-200012-6 (2019) [E1]

|

Open Research Newcastle | |||||||||

| 2019 |

Cuskelly D, Fraser B, Reed S, Post A, Copus M, Kisi E, 'Thermal storage for CSP with miscibility gap alloys', Proceedings of the 24th SolarPACES International Conference (SolarPACES 2018), 2126, 200013-1-200013-9 (2019) [E1]

|

Open Research Newcastle | |||||||||

| 2017 |

Cuskelly D, McBride W, 'A new, common, experiential ‘Engineering Practice’ course', 28th Annual Conference of the Australasian Association for Engineering Education (AAEE 2017), 337-345 (2017) [E1]

|

Open Research Newcastle | |||||||||

| Show 3 more conferences | |||||||||||

Journal article (23 outputs)

| Year | Citation | Altmetrics | Link | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2026 |

Cuskelly D, Maddison G, Vacek P, Fairclough SM, Midgley PA, Seita M, 'Effect of energy density on microstructure control in precipitation hardening steel during powder bed fusion', Materials Research Letters (2026)

|

||||||||||

| 2025 |

Wensrich CM, Holman S, Lionheart WBL, Luzin V, Cuskelly D, Kirstein O, Salvemini F, 'Well-posedness and trivial solutions to inverse eigenstrain problems', International Journal of Solids and Structures, 321 (2025) [C1]

|

||||||||||

| 2024 |

Allen J, Cranney W, Cuskelly D, Moradmand S, 'The impact of 3-dimensional anode geometry on the electrochemical response of high temperature gas evolution reactions in molten salts', ELECTROCHIMICA ACTA, 483 (2024) [C1]

|

||||||||||

| 2024 |

Merz J, Cuskelly D, Richardson P, 'MAB phase-alumina composite formation via aluminothermic exchange reactions', MATERIALS LETTERS, 360 (2024) [C1]

|

Open Research Newcastle | |||||||||

| 2023 |

Allen J, Lee J, Moradmand S, Cuskelly D, 'Optimal pre-treatment of a Ni-11Fe-10Cu anode for efficient molten salt electrolysis of carbon dioxide: Toward net-zero emission manufacturing', ELECTROCHIMICA ACTA, 469 (2023) [C1]

|

Open Research Newcastle | |||||||||

| 2023 |

Merz J, Cuskelly D, Gregg A, Studer A, Richardson P, 'On the complex synthesis reaction mechanisms of the MAB phases: High-speed in-situ neutron diffraction and ex-situ X-ray diffraction studies of MoAlB', CERAMICS INTERNATIONAL, 49, 38789-38802 (2023) [C1]

|

Open Research Newcastle | |||||||||

| 2021 |

Merz J, Richardson P, Cuskelly D, 'Formation of Mn2AlB2 by induction-assisted self-propagating high-temperature synthesis', OPEN CERAMICS, 8 (2021) [C1]

Rapid formation of the MAB phase ceramic, Mn2AlB2, by the method of induction furnace-assisted self-propagating high-temperature synthesis (SHS) was investigated in thi... [more] Rapid formation of the MAB phase ceramic, Mn2AlB2, by the method of induction furnace-assisted self-propagating high-temperature synthesis (SHS) was investigated in this work. The effects of Al content, high-energy ball-milling and cold pressing load on phase purity and reaction behaviour were also examined. An Al content of 140% allowed the highest conversion of reactants to Mn2AlB2. Increasing ball-milling time was shown to increase phase purity and reduce SHS ignition and peak temperatures. Unpressed powder samples exhibited higher phase purities and significantly lower SHS ignition temperatures than pressed samples. It was revealed that Mn2AlB2 forms by a two-stage reaction in this process, as evidenced by the presence of two exothermic peaks in the temperature-time data. The short synthesis times and equipment scalability available using this method offer a unique solution for the large-scale fabrication of MAB phase powders.

|

Open Research Newcastle | |||||||||

| 2021 |

Richardson PJ, Keast VJ, Cuskelly DT, Kisi EH, 'Theoretical and experimental investigation of the W-Al-B and Mo-Al-B systems to approach bulk WAlB synthesis', JOURNAL OF THE EUROPEAN CERAMIC SOCIETY, 41, 1859-1868 (2021) [C1]

|

Open Research Newcastle | |||||||||

| 2021 |

Richardson P, Cuskelly D, Brandt M, Kisi E, 'Effects of furnace annealing on in situ reacted Ti2AlC MAX phase composite coatings deposited by laser cladding', SURFACE & COATINGS TECHNOLOGY, 405 (2021) [C1]

|

Open Research Newcastle | |||||||||

| 2021 |

Tegg L, Cuskelly D, Studer AJ, Richardson P, Kisi E, Keast VJ, 'Intermediate Phases and Reaction Kinetics of the Furnace-Assisted Synthesis of Sodium Tungsten Bronze Nanoparticles', JOURNAL OF PHYSICAL CHEMISTRY C, 125, 8185-8194 (2021) [C1]

|

Open Research Newcastle | |||||||||

| 2020 |

Richardson P, Cuskelly D, Brandt M, Kisi E, 'Microstructural analysis of in-situ reacted Ti2AlC MAX phase composite coating by laser cladding', Surface and Coatings Technology, 385 (2020) [C1]

|

Open Research Newcastle | |||||||||

| 2019 |

Copus M, Fraser B, Reece R, Hands S, Cuskelly D, Sugo H, Reed S, Bradley J, Post A, Kisi E, 'On-sun testing of Miscibility Gap Alloy thermal storage', SOLAR ENERGY, 177, 657-664 (2019) [C1]

|

Open Research Newcastle | |||||||||

| 2018 |

Tegg L, Cuskelly D, Keast VJ, 'Plasmon Responses in the Sodium Tungsten Bronzes', PLASMONICS, 13, 437-444 (2018) [C1]

|

Open Research Newcastle | |||||||||

| 2018 |

Tegg L, Cuskelly D, Keast VJ, 'Bulk scale fabrication of sodium tungsten bronze nanoparticles for applications in plasmonics', NANOTECHNOLOGY, 29 (2018) [C1]

|

Open Research Newcastle | |||||||||

| 2017 |

Rawson AJ, Cuskelly DT, Driver SL, Carpenter MA, 'Elastic and anelastic properties of metals near their melting points from miscibility gap alloy composites', MATERIALS SCIENCE AND ENGINEERING A-STRUCTURAL MATERIALS PROPERTIES MICROSTRUCTURE AND PROCESSING, 681, 18-24 (2017) [C1]

|

Open Research Newcastle | |||||||||

| 2017 |

Tegg L, Cuskelly D, Keast VJ, 'The sodium tungsten bronzes as plasmonic materials: fabrication, calculation and characterization', MATERIALS RESEARCH EXPRESS, 4 (2017) [C1]

|

Open Research Newcastle | |||||||||

| 2016 |

Cuskelly DT, Kisi EH, 'Single-Step Carbothermal Synthesis of High-Purity MAX Phase Powders', JOURNAL OF THE AMERICAN CERAMIC SOCIETY, 99, 1137-1140 (2016) [C1]

The Mn+1AXn phases Cr2GeC and Cr2GaC were synthesized with high phase-purity directly from Cr2O3; Ge or Ga; and C using a single-step carbothermal reduction. X-ray diff... [more] The Mn+1AXn phases Cr2GeC and Cr2GaC were synthesized with high phase-purity directly from Cr2O3; Ge or Ga; and C using a single-step carbothermal reduction. X-ray diffraction and scanning electron microscope analysis of the materials shows them to be >99 mol% Cr2GeC and 92 mol% Cr2GaC, respectively. Extension to non-Cr systems is briefly demonstrated by applying the method to the synthesis of V2GeC.

|

Open Research Newcastle | |||||||||

| 2016 |

Cuskelly D, Richards E, Kisi E, 'MAX phase - Alumina composites via elemental and exchange reactions in the Ti(n+1)AC(n) systems (A=Al, Si, Ga, Ge, In and Sn)', JOURNAL OF SOLID STATE CHEMISTRY, 237, 48-56 (2016) [C1]

Extension of the aluminothermal exchange reaction synthesis of Mn+1AXn phases to systems where the element 'A' is not the reducing agent was investigated in s... [more] Extension of the aluminothermal exchange reaction synthesis of Mn+1AXn phases to systems where the element 'A' is not the reducing agent was investigated in systems TiO2-A-Al-C for A=Al, Si, Ga, Ge, In and Sn as well as Cr2O3-Ga-Al-C. MAX phase-Al2O3 composites were made in all systems except those with A=Ga or In. The effectiveness of conversion to MAX phases was generally in the range 63-96% without optimisation of starting ratios. Optimisation in the Ti-Si-C system gave a MAX phase component with >98% Ti3SiC2.

|

Open Research Newcastle | |||||||||

| 2016 |

Cuskelly DT, Kisi EH, Sugo HO, 'MAX phase - Alumina composites via exchange reaction in the Mn+1AlCn systems (M=Ti, V, Cr, Nb, or Ta)', JOURNAL OF SOLID STATE CHEMISTRY, 233, 150-157 (2016) [C1]

|

Open Research Newcastle | |||||||||

| 2015 |

Cuskelly DT, Richards ER, Kisi EH, Keast VJ, 'Ti3GaC2 and Ti3InC2: First bulk synthesis, DFT stability calculations and structural systematics', JOURNAL OF SOLID STATE CHEMISTRY, 230, 418-425 (2015) [C1]

|

Open Research Newcastle | |||||||||

| 2015 |

Hasan MM, Cuskelly D, Sugo H, Kisi EH, 'Low temperature synthesis of low thermionic work function (LaxBa1-x)B6', JOURNAL OF ALLOYS AND COMPOUNDS, 636, 67-72 (2015) [C1]

This study presents investigations of the microstructure, morphology and emission properties of the promising thermionic material (LaxBa1-x)B6. The material was synthes... [more] This study presents investigations of the microstructure, morphology and emission properties of the promising thermionic material (LaxBa1-x)B6. The material was synthesised by solid-state reaction without post-synthesis purifications. Powder X-ray diffraction revealed that samples prepared at a temperature =1500 °C had formed a significant proportion of solid solution (above 54 mass%). Subsequent sintering at 1950 °C caused the formation of a mixture of three solid solutions with the dominant phase being (La0.31Ba0.69)B6 ~85% (by mass). The Richardson work function and emission constant for this boride mixture were found to be 1.03 eV and 8.44 × 10-6 A cm K-2 respectively.

|

Open Research Newcastle | |||||||||

| 2015 |

Keast VJ, Ewald J, De Silva KSB, Cortie MB, Monnier B, Cuskelly D, Kisi EH, 'Optical properties and electronic structure of the Cu-Zn brasses', JOURNAL OF ALLOYS AND COMPOUNDS, 647, 129-135 (2015) [C1]

The color of Cu-Zn brasses range from the red of copper through bright yellow to grey-silver as the Zn content increases. Here we examine the mechanism by which these c... [more] The color of Cu-Zn brasses range from the red of copper through bright yellow to grey-silver as the Zn content increases. Here we examine the mechanism by which these color changes occur. The optical properties of this set of alloys has been calculated using density functional theory (DFT) and compared to experimental spectroscopy measurements. The optical response of the low Zn content a-brasses is shown to have a distinctly different origin to that in the higher content ß', ¿ and e-brasses. The response of ß'-brass is unique in that it is strongly influenced by an overdamped plasmon excitation and this alloy will also have a strong surface plasmon response.

|

Open Research Newcastle | |||||||||

| 2013 |

Sugo H, Kisi E, Cuskelly D, 'Miscibility gap alloys with inverse microstructures and high thermal conductivity for high energy density thermal storage applications', Applied Thermal Engineering, 51, 1345-1350 (2013) [C1]

|

Open Research Newcastle | |||||||||

| Show 20 more journal articles | |||||||||||

Grants and Funding

Summary

| Number of grants | 6 |

|---|---|

| Total funding | $272,688 |

Click on a grant title below to expand the full details for that specific grant.

20253 grants / $48,325

Erosion rate and Particle Characterization Campaigns - FPR Energy$19,862

Funding body: FPR Energy Limited

| Funding body | FPR Energy Limited |

|---|---|

| Project Team | Assoc Prof Thomas Fiedler, Dr Dylan Cuskelly |

| Scheme | TRaCE R&D Voucher |

| Role | Investigator |

| Funding Start | 2025 |

| Funding Finish | 2026 |

| GNo | G2501136 |

| Type Of Funding | C3100 – Aust For Profit |

| Category | 3100 |

| UON | Y |

Erosion rate and Particle Characterization Campaigns - FPR Energy$19,861

Funding body: University of New South Wales

| Funding body | University of New South Wales |

|---|---|

| Project Team | Assoc Prof Thomas Fiedler, Dr Dylan Cuskelly |

| Scheme | TRaCE R&D Vouchers |

| Role | Investigator |

| Funding Start | 2025 |

| Funding Finish | 2026 |

| GNo | G2501183 |

| Type Of Funding | Scheme excluded from IGS |

| Category | EXCL |

| UON | Y |

Sunburn space flight computer$8,602

Funding body: Sunburnt Space Co Pty Ltd

| Funding body | Sunburnt Space Co Pty Ltd |

|---|---|

| Project Team | Dr Dylan Cuskelly |

| Scheme | Research Grant |

| Role | Lead |

| Funding Start | 2025 |

| Funding Finish | 2025 |

| GNo | G2500475 |

| Type Of Funding | C3100 – Aust For Profit |

| Category | 3100 |

| UON | Y |

20221 grants / $11,863

iSTEM Zero to Hero$11,863

Funding body: Google Australia Pty Ltd

| Funding body | Google Australia Pty Ltd |

|---|---|

| Project Team | Dr Dylan Cuskelly, Doctor Alexander Gregg |

| Scheme | Educator Grants |

| Role | Lead |

| Funding Start | 2022 |

| Funding Finish | 2022 |

| GNo | G2200629 |

| Type Of Funding | C3100 – Aust For Profit |

| Category | 3100 |

| UON | Y |

20201 grants / $20,500

Thermal energy storage materials from a specialised family of materials$20,500

Funding body: University of Melbourne

| Funding body | University of Melbourne |

|---|---|

| Project Team | Dr Dylan Cuskelly, Mr Mark Copus |

| Scheme | AMSI Australian Postgraduate Research Internships |

| Role | Lead |

| Funding Start | 2020 |

| Funding Finish | 2020 |

| GNo | G2001059 |

| Type Of Funding | Scheme excluded from IGS |

| Category | EXCL |

| UON | Y |

20191 grants / $192,000

Optimisation of the Manufacture of Thermal Energy Storage Modules$192,000

Funding body: MGA Thermal Pty Ltd

| Funding body | MGA Thermal Pty Ltd |

|---|---|

| Project Team | Dr Dylan Cuskelly, Prof Erich Kisi |

| Scheme | Research Grant |

| Role | Lead |

| Funding Start | 2019 |

| Funding Finish | 2020 |

| GNo | G1901499 |

| Type Of Funding | C3100 – Aust For Profit |

| Category | 3100 |

| UON | Y |

Research Supervision

Number of supervisions

Current Supervision

| Commenced | Level of Study | Research Title | Program | Supervisor Type |

|---|---|---|---|---|

| 2021 | PhD | Prometheus: A Device to Produce Electricity From Stored Compressed Air | PhD (Chemical Engineering), College of Engineering, Science and Environment, The University of Newcastle | Principal Supervisor |

Past Supervision

| Year | Level of Study | Research Title | Program | Supervisor Type |

|---|---|---|---|---|

| 2024 | PhD | Synthesis and Characterisation of MAB Phase Ceramics via In-situ and Ex-situ Techniques | PhD (Mechanical Engineering), College of Engineering, Science and Environment, The University of Newcastle | Principal Supervisor |

| 2021 | PhD | Exploratory Study Into Advanced Thermal Energy Storage Materials and Thermal Coatings for Survival in the Urban Environment | PhD (Mechanical Engineering), College of Engineering, Science and Environment, The University of Newcastle | Co-Supervisor |

| 2021 | PhD | Development and Investigation of Large Scale Miscibility Gap Alloys | PhD (Mechanical Engineering), College of Engineering, Science and Environment, The University of Newcastle | Co-Supervisor |

| 2021 | PhD | Synthesis and Characterisation of Ternary Nano-laminated Ceramics for Emerging Technologies | PhD (Mechanical Engineering), College of Engineering, Science and Environment, The University of Newcastle | Co-Supervisor |

| 2020 | PhD | Synthesis and Characterisation of Sodium Tungsten Bronze Nanoparticles for Applications in Plasmonics | PhD (Physics), College of Engineering, Science and Environment, The University of Newcastle | Co-Supervisor |

News

News • 11 Sep 2025

NU Rocketry Crowned Overall Champions at the 2025 Australian Universities Rocket Competition

NU Rocketry has soared to victory, claiming the title of Overall Winner at the 2025 Australian Universities Rocket Competition (AURC), held at the Endeavour Aerospace launch site in White Cliffs, NSW.

News • 11 Sep 2025

NU Rocketry Crowned Overall Champions at the 2025 Australian Universities Rocket Competition

NU Rocketry has soared to victory, claiming the title of Overall Winner at the 2025 Australian Universities Rocket Competition (AURC), held at the Endeavour Aerospace launch site in White Cliffs, NSW.

Dr Dylan Cuskelly

Position

Lecturer

School of Engineering

College of Engineering, Science and Environment

Contact Details

| dylan.cuskelly@newcastle.edu.au |

Office

| Room | ES315 |

|---|---|

| Building | Engineering Science |

| Location | Callaghan Campus University Drive Callaghan, NSW 2308 Australia |