Research

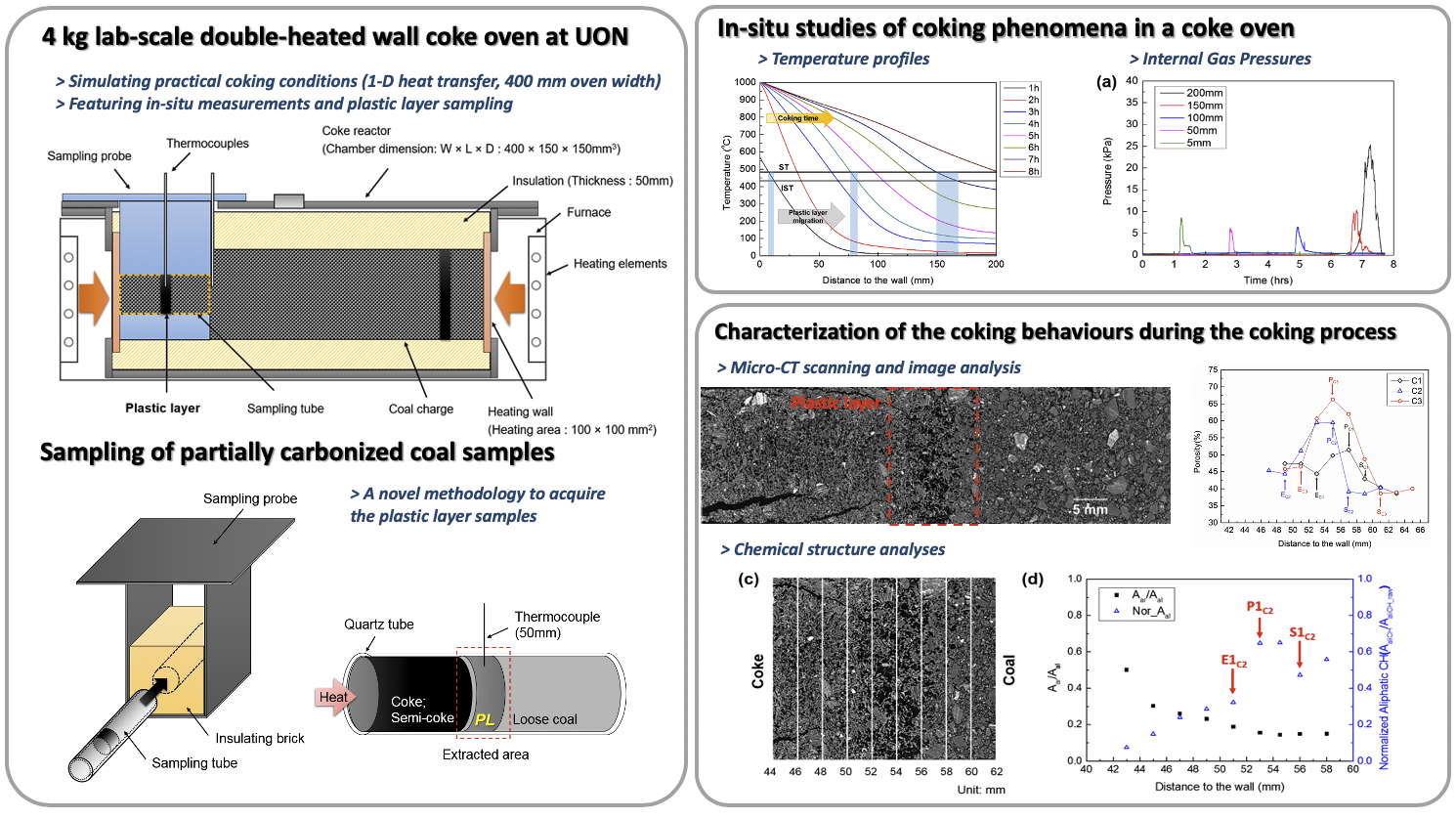

Innovative coking research

One of the significant research priorities of the ICCCF is to investigate the underlying mechanism of coking behaviours of coking coals and blends in commercial coke ovens. ICCCF has developed a unique 4 kg laboratory-scale double-heated wall coke oven that simulates the heating conditions inside industrials ovens. The research focuses on fundamental investigation of the thermoplastic behaviours and subsequent coking behaviours of coking coal during the coking process with the overall objectives of:

- Gain a fundamental understanding of the thermoplastic behaviours and mass transport mechanisms of Australian coking coals during the coking process;

- Characterise the evolution of carbon structures in coke/semi-coke regions (post-thermoplastic region) and the establishment of a 3D model of a coke structure;

- Study the interactions between components in coal blends as they are heated during the coking process;

- Investigate the in-situ coking phenomena including temperature profile, internal gas pressure and oven wall pressure;

- Better understand of the influence of a variety of coal properties (i.e. coal rank, maceral composition and rheological property), and coking conditions inside the coke oven on the structures and quality of product coke and the relevant coking phenomena.

This study has significantly deepened a fundamental understanding of the underlying chemical and physical mechanisms of coking behaviours of Australian coking coals. The findings of cokemaking research at ICCCF has the potential to provide an improved understanding of coking behaviours Australian coking coal that can pave the way for enhancing the models used to predict the coke strength and reactivity in the cokemaking industry. The overall goal is to provide innovative solutions to the Australian coal industry to maximize the value and share of Australian coking coal in the international markets and better address the challenges facing the coal and cokemaking industry in the long run.

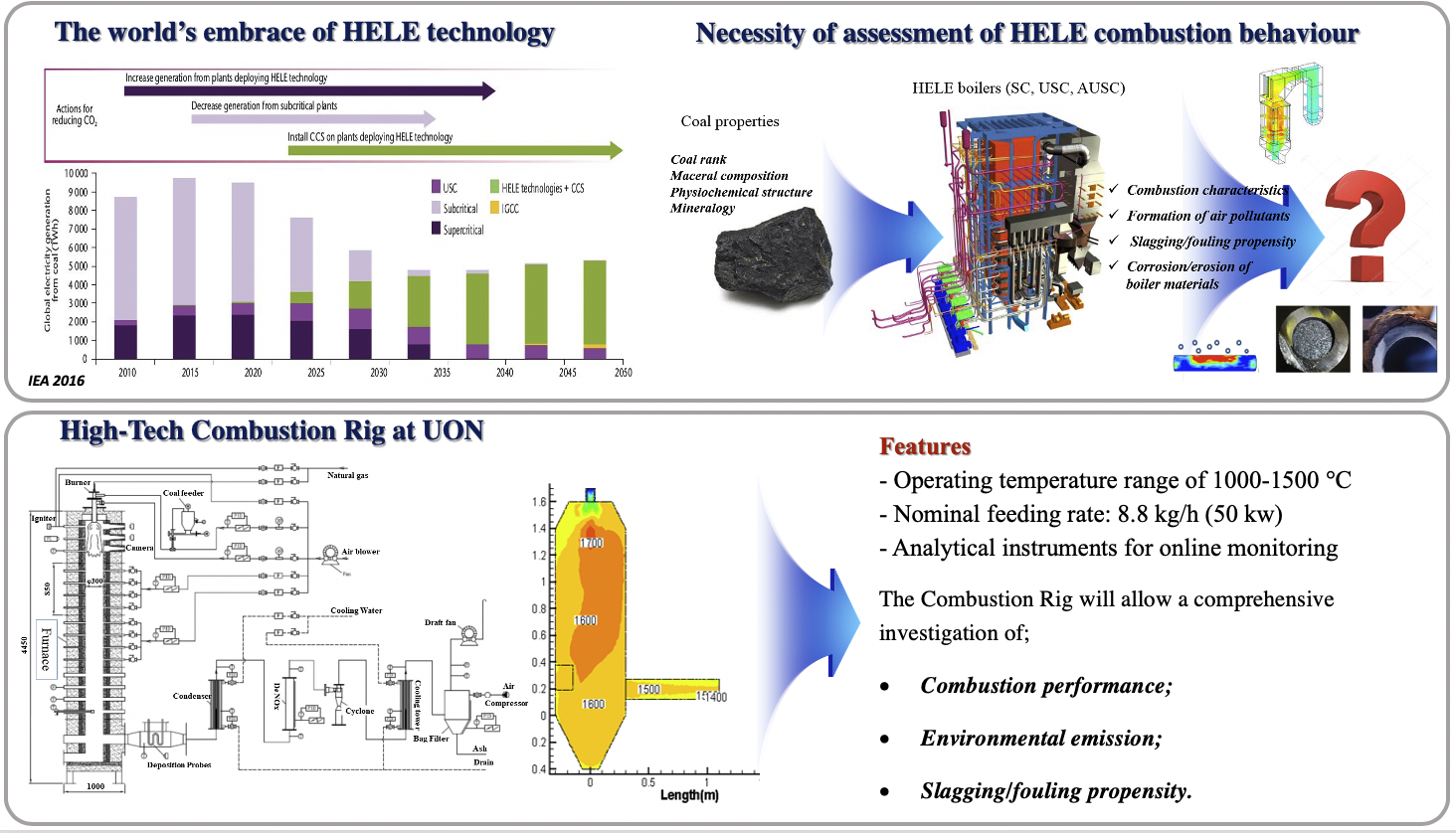

Combustion behavior of thermal coal under advanced coal-fired power systems

Australian thermal coal has maintained an increasingly important role in energy supply in Australia and overseas. There is a growing need for a convenient and comprehensive combustion testing of Australian thermal coals under the conditions of emerging advanced high efficiency- low emission (HELE) coal-fired boiler systems to support the marketing of Australian thermal coal in Australia and internationally. In this context, ICCCF is developing a 50 kW pilot-scale high-tech combustion testing facility to enhance an understanding of combustion behaviours of Australian thermal coals in advanced combustion systems with specific objectives of:

- Initiate the development of a comprehensive testing methodology and combustion performance database to allow a better assessment of the suitability of Australian thermal coals for HELE boilers (Supercritical and ultra-supercritical PF boilers).

- Experimentally identify the properties of parent coal (coal chemistry, rank, maceral composition, mineralogy, etc.) that influence the combustibility of thermal coals under conditions relevant to HELE boilers;

- Assess the performance of Australian thermal coals in relation to the requirements of burnout efficiency and reactivity, emissions, and corrosion of boiler materials under HELE combustion conditions;

- Investigate the ignition behaviour, flame chemistry and stability, mineral transformation, slagging/fouling, and flue gas chemistry of Australian thermal coals.

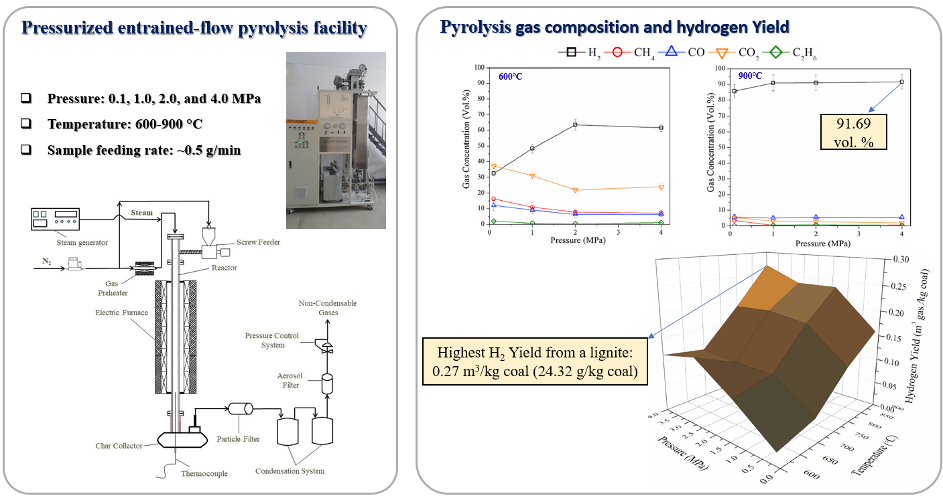

Hydrogen production from pressurized pyrolysis of coal and biomass

Hydrogen has been regarded as a clean and promising energy source globally. The advanced hydrogen production processes have gained tremendous attention across the world. The research findings at the ICCCF have demonstrated that enhanced production of hydrogen-rich gas can be achieved via pyrolysis of coal and biomass at higher pressures and temperatures under pressurized entrained-flow pyrolysis conditions. ICCCF has designed and developed an advanced pressurized entrained-flow pyrolysis test facility that has been used successfully to demonstrate the concept. The research focuses on the fundamental investigation of the pyrolysis mechanisms, reaction pathways and process optimization to increase the selectivity of target products. The overall objectives are:

- Fundamental investigation of the pyrolysis mechanisms of a variety of coal and biomass under fast heating rates;

- Analysis of pyrolysis gas composition (H2, CH4, CO, CO2, and C2H6) and determine the yield of hydrogen under various process conditions;

- Understanding the influence of pressure and temperature on the thermal decomposition behavior of coal and biomass;

- Optimize the process parameters to allow scale-up of the process for large-scale production of hydrogen and chemical raw materials.

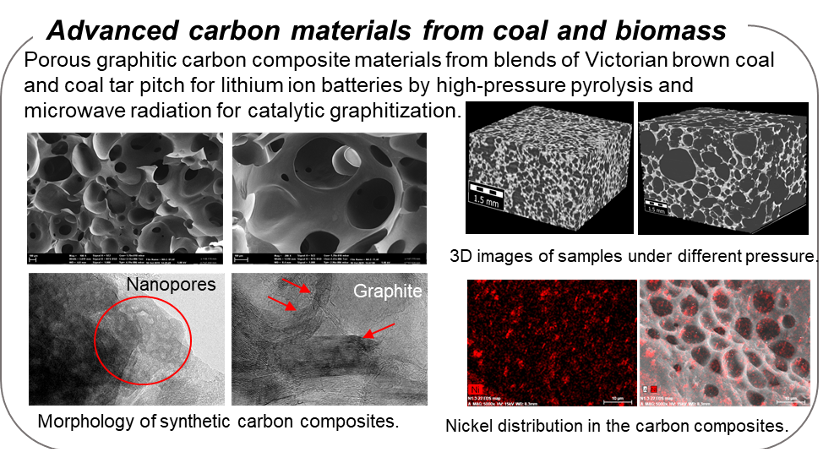

Advanced carbon materials derived from coal and biomass for energy storage

With the shift of global focus on the clean energy technologies and efficient energy storage systems, the development advanced carbon materials has gained increasing interest globally. In this context, ICCCF has strived to utilize the vast resources of low-grade coal and biomass in Australia as precursors for advanced carbon materials. With unique features of high surface area and reactivity and low ash content, Victorian brown coal (VBC) is a promising raw material for the development of low-cost advanced carbon materials. ICCCF has developed innovative technologies for the conversion of brown coal to high-value porous graphitic carbon composite materials to be applied in energy storage. Addressing the issues associated with the low fluidity of brown coal, we have used coal tar pitch as an additive to tailor the pore structure of the carbon materials. This process involves high-pressure pyrolysis and microwave catalytic graphitization to fabricate brown coal-based carbon foams and to investigate the pore and carbon structure evolution of the carbon foam during the fabrication process. The overall objectives include:

- Explore the suitability of brown coal as a precursor for the synthesis of advanced carbon materials for energy storage.

- Investigate the fabrication of foam-like carbon composite materials from the blend of brown coal with coal tar pitch.

- Better understand the evolution of pore structure during high-pressure pyrolysis and the development of graphitic microstructure to optimize for the process.

- Utilize the synthetic porous graphitic composites as anode materials in lithium-ion battery applications. The aim is to understand the influence of the properties of composite materials on the battery performance.

- Investigating the effect of inherent heteroatoms in the composite carbon material on the catalytic graphitization process and electrochemical performance.

The University of Newcastle acknowledges the traditional custodians of the lands within our footprint areas: Awabakal, Darkinjung, Biripai, Worimi, Wonnarua, and Eora Nations. We also pay respect to the wisdom of our Elders past and present.