Printed Solar

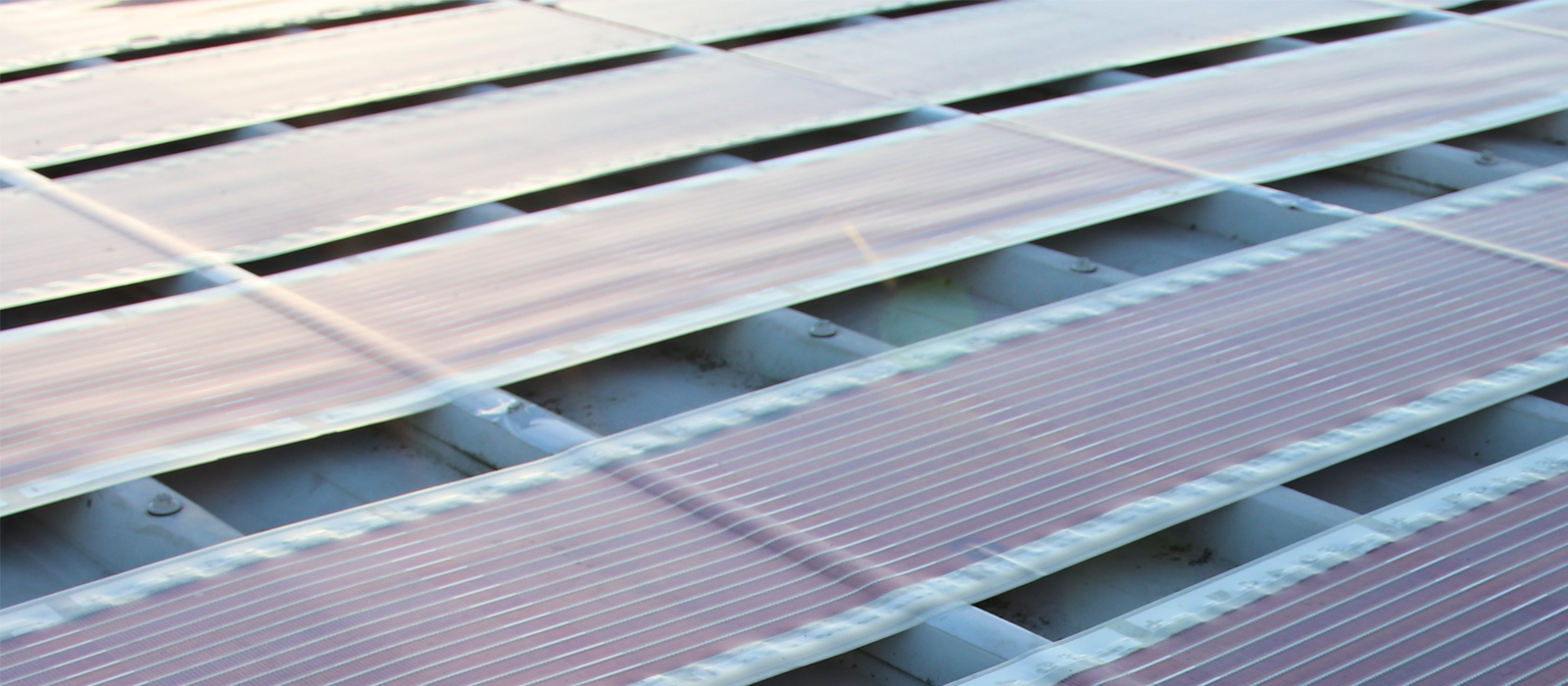

In late 2018 we became the first research group in Australia, possibly the world, to embark on a commercial scale installation of printed solar, in partnership with CHEP. This game-changing material is incredibly low cost, ultra thin, light weight, robust, flexible and recyclable. It's manufactured using uncomplicated, conventional print technologies along with our revolutionary electronic inks in a new form of advanced manufacturing known as functional printing.

Aimed at significantly increasing the global uptake of renewable energy technologies and dramatically reducing energy bills, this technology is the result of almost two decades of research and development.

Our partnership with the Australian National Fabrication Facility (ANFF) offers us the unique ability to develop materials and manufacture the printed solar cells entirely in-house in our laboraties based at the Newcastle Institute for Energy and Resources (NIER).

The University of Newcastle acknowledges the traditional custodians of the lands within our footprint areas: Awabakal, Darkinjung, Biripai, Worimi, Wonnarua, and Eora Nations. We also pay respect to the wisdom of our Elders past and present.