Inverted device structure organic solar cells with nanoparticulate active layer

Inverted device structure organic solar cells with nanoparticulate active layer

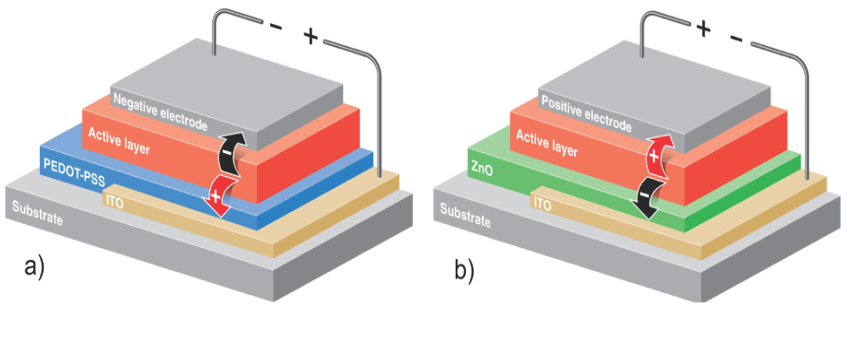

The purpose of my project is to rectify two specific problems with OPV devices in order to allow large scale production. The first of these is that the lifetime of the devices is currently too short to be practicable. The remedy that has been proposed is the use of a different structure. The structure of the device determines which materials can be used and the ways in which the layers interact. The image below shows the two most heavily researched structures. The standard structure, in a), was most widely used until recently. However, the inverted structure, in b), has been observed to have a longer lifetime. The use of the inverted structure allows more stable materials to be used in the electrodes and layers.

The other problem is the use of chlorinated solvents, such as chloroform, in the active layer. The active layer in an OPV generally consists of a conjugated polymer and fullerene mixture deposited from a chlorinated solvent. This presents problems when considering large scale production for a number of reasons. Chlorinated solvents are volatile and can pose a wide variety of health and safety issues, they are expensive driving the cost of OPV devices up significantly and they can also be harmful to the environment. This project aims to incorporate a water-based active layer, made with polymer nanoparticles, into an inverted device structure in order to remove these problems. This is the first time this has been attempted.

The University of Newcastle acknowledges the traditional custodians of the lands within our footprint areas: Awabakal, Darkinjung, Biripai, Worimi, Wonnarua, and Eora Nations. We also pay respect to the wisdom of our Elders past and present.