Emeritus Professor Graeme Jameson

Emeritus Professor

School of Engineering (Chemical Engineering)

- Email:graeme.jameson@newcastle.edu.au

- Phone:(02) 4921 6181

A revolution in mining and engineering

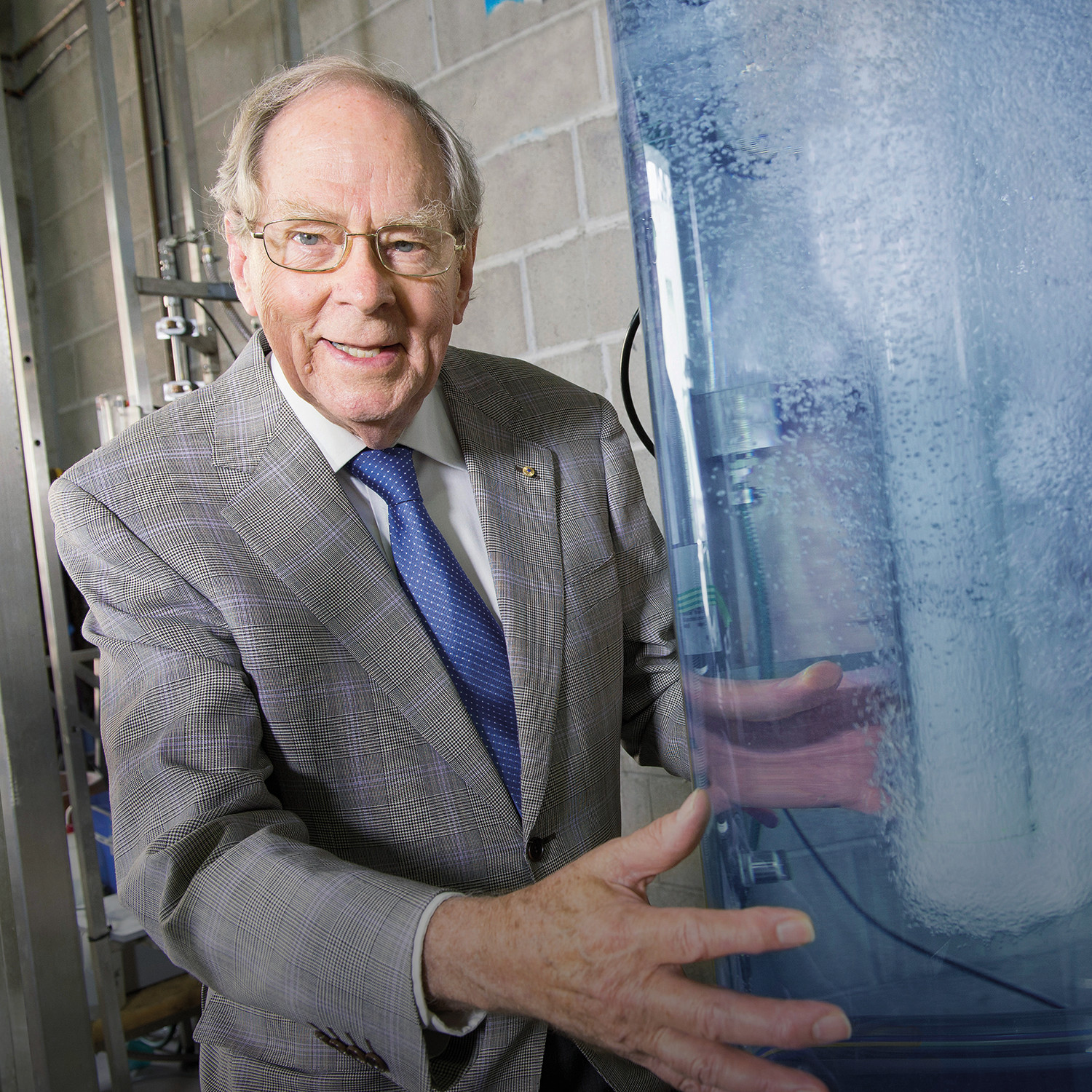

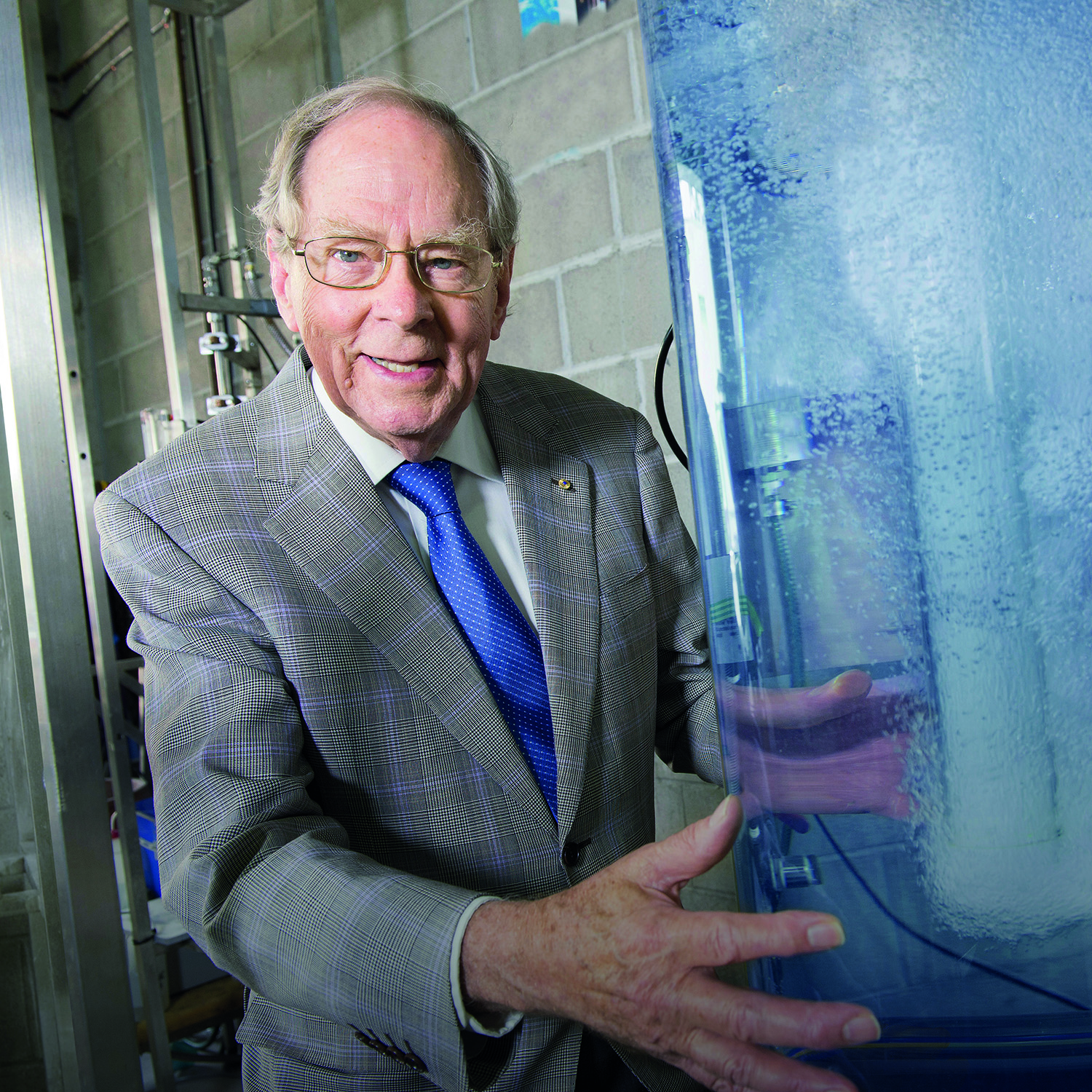

Laureate Professor Graeme Jameson is a globally renowned researcher in the field of mineral processing and the acclaimed inventor of the Jameson Cell, a froth flotation device that has delivered big wins for the environment and is considered Australia’s biggest-earning innovation for the past quarter century.

Laureate Professor Graeme Jameson’s work has revolutionised the way valuable minerals, the bedrock of the Australian economy, are extracted from rocks. His most famous invention, the Jameson Cell, has netted Australia roughly $51 billion in exports.

Named after its inventor, the Jameson Cell has also led to significant savings in Australia’s energy consumption and reductions in greenhouse gas emissions — and earned Graeme almost legendary status in mining and engineering circles.

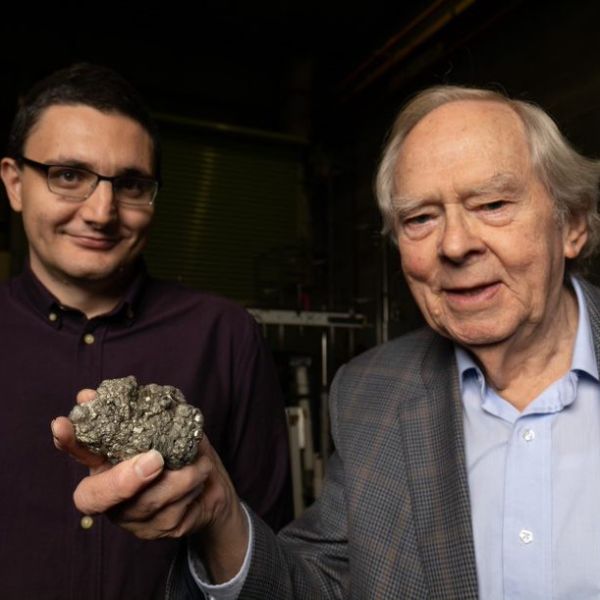

Graeme is now working to bring his latest award-winning invention, the NovaCell, to commercial reality.

Graeme’s remarkable achievements and enduring reputation as a prominent global expert attract high numbers of talented engineering students, researchers and academics to the University of Newcastle every year.

A billion-dollar idea

The Jameson Cell is an ingenious flotation device that changed the way minerals could be recovered. It has become a global industry gold standard and is now featured in undergraduate textbooks for aspiring engineers worldwide.

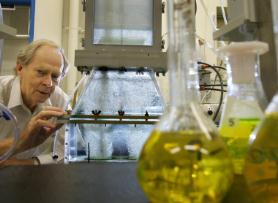

The process involves grinding mineral ores into small particles, suspending them in water and placing them into stirred tanks known as cells. The Jameson Cell blows air bubbles up through the liquid and uses reagents to make mineral particles stick to them. The bubbles form a mineral-rich froth on the surface, which is then scraped off.

A large mine can treat 10,000 tonnes an hour — that's similar to 10,000 small cars being reduced to dust every hour.

"I had been looking at ways to improve the flotation process for many years. I knew flotation was important to the Australian industry and felt the answer lay in the mechanics of fluids and particles,” explains Graeme.

The technology was developed for commercial application in partnership with Mount Isa Mines Limited, who Graeme says, “quickly identified the cell’s potential”.

These days, there are more than 300 Jameson Cells in operation across 25 countries, being used for copper, coal, zinc, nickel, lead, silver and platinum extraction worldwide.

The Cell has also been used for environmental applications, including extracting oil from tar sands in Canada, cleaning up industrial wastewaters in Newcastle and other locations in Australia, and removing blue-green algae from waterways in inland Australia.

The finely-ground particles that were once too small to recover and previously were dumped into rivers, or buried, can now be processed. Old mines now have a longer life, and the environmental damage caused by the need to open more new mines is reduced.

The NovaCell

Graeme now has his sights set on an exciting invention which he calls the NovaCell: a radical way of recovering coarse mineral particles as large as beach sand. The NovaCell uses a fluidised bed to collect coarse particles and a high shear aeration zone for ultra-fines separation.

Graeme likens his new technology to the landscape that Newcastle is famous for — the beach.

"Imagine a bed of sand. If you're well away from the water the sand will be pretty stable and if you stand on it, you don't sink. However, if you go a bit closer to the water you can make the sand fluidise just by moving your feet up and down.”

"The sand stays more or less in the same place but the water in the sand is pumped up and down and momentarily it lifts particles away from their neighbours, so the sand becomes liquid-like and you can sink down into it.

"The fluidised bed flotation device uses the same principles by pushing air bubbles through the sediment and this creates a quiet environment for the larger particles to attach to the bubbles."

Simply put, the Cell could eliminate the need to grind ore very finely, resulting in big savings — both financially, and for the environment through a reduction in greenhouse gas emissions, and energy and water consumption. The device shows a 40% reduction in comminution energy and a 10% reduction in overall site operating costs.

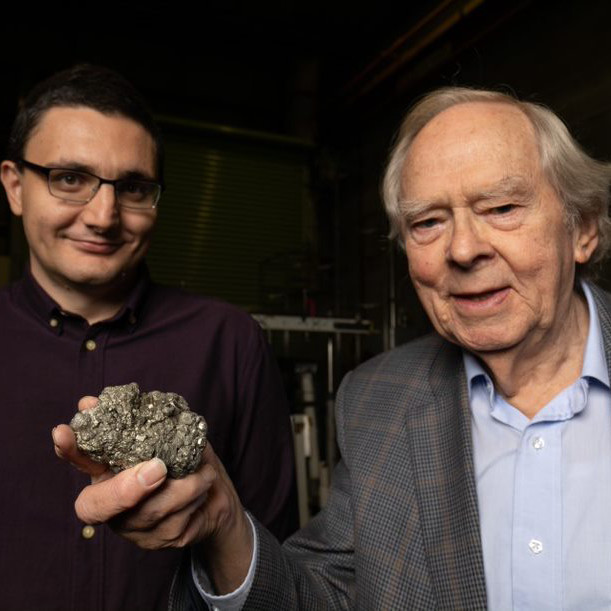

The NovaCell has already generated a buzz within the industry, and secured Graeme the prestigious 2019 CEEC Medal for Technical Research alongside his Research Associate Dr Cagri Emer.

Challenges of time and money

Graeme knows only too well how difficult it can be to take a fledging idea and turn it into a commercially viable product. Research oriented towards solving industrial problems takes a good deal of time, determination, and funding.

“Solutions can take a long time to bring to fruition. If one fails to solve a problem, the problem does not go away and you can’t pivot your research in another direction, you have to keep going.”

“But the biggest barrier is what is known as The Gap. This refers to the funding of the intermediate stage of commercial development.

“Once a prototype has been developed and tested, it is not so difficult to find an industrial partner to take up the idea. However, the inventor must find the costs for the prototype, and the funding for this step is very difficult to find.”

Creating a legacy

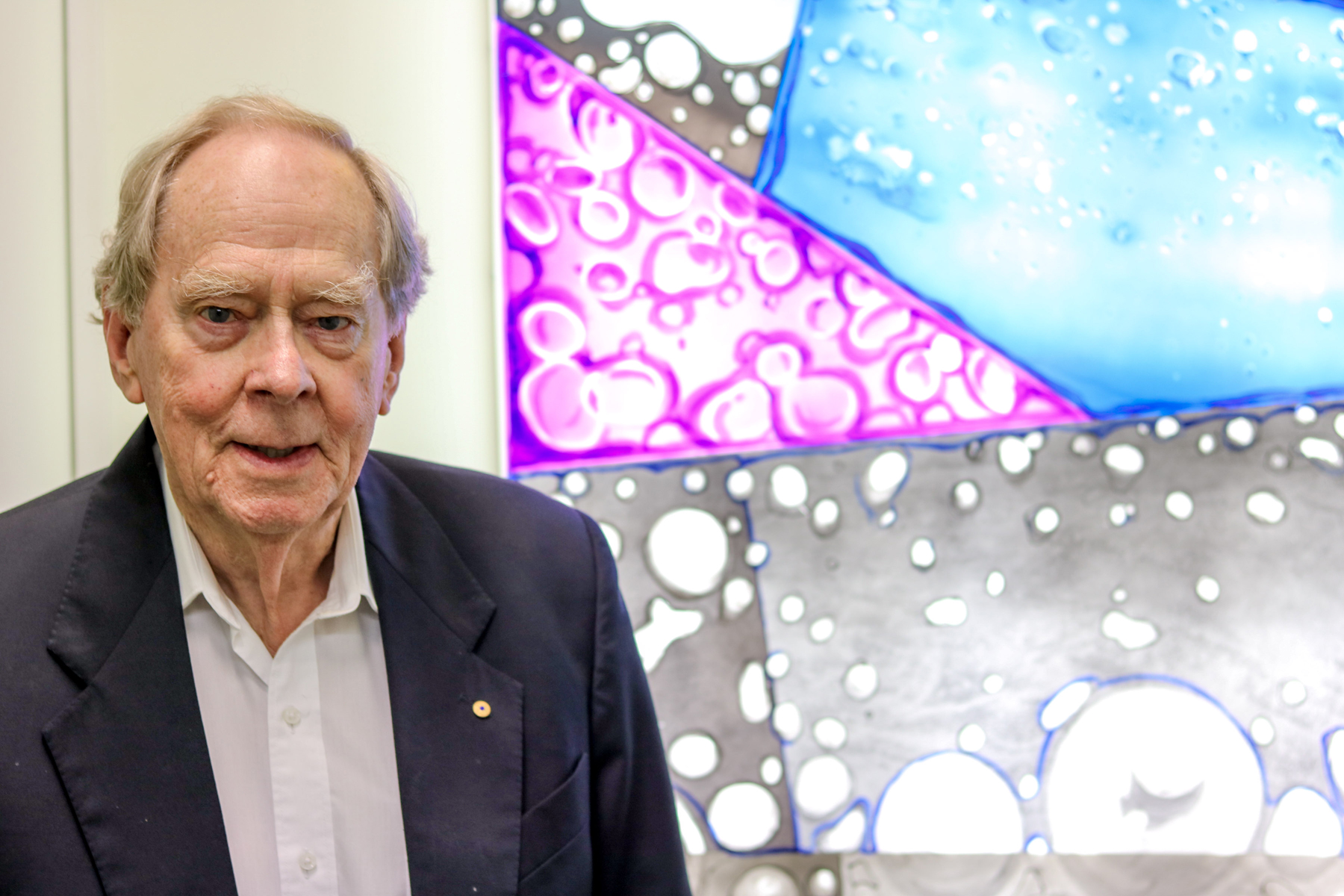

Graeme has clocked up countless achievements over his impressive career.

He received an Order of Australia Medal, AO, in 2005, the Antoine M. Gaudin Medal in 2013, the inaugural Prime Minister's Prize for Innovation in 2015 and the Peter Nicol Russell Memorial Medal from the Institution of Engineers Australia for outstanding service to his profession.

In 2018, Graeme was elected to the world’s oldest and highly prestigious scientific society, the Royal Society of London. The Society’s wall of fame includes names such as Newton, Darwin, Hawking and Einstein. Graeme describes the election as, “the most rewarding moment in my career”.

Ever humble despite his growing list of accolades and accomplishments, Graeme’s work is

underscored by his unyielding commitment to producing real-world solutions and creating a lasting legacy for communities and our nation.

"I see science and technology as agents for improving people's lives. I believe that if you're going to put your heart into something, you may as well tackle a problem that will make a difference and benefit the community.”

With a number of prospects still emerging from his latest research, Graeme continues to be a gold mine of innovation for Australian industry.

A revolution in mining and engineering

Laureate Professor Graeme Jameson is a globally renowned researcher in the field of mineral processing and the acclaimed inventor of the environmentally friendly Jameson Cell, a froth flotation device that is Australia’s biggest-earning innovation for the past quarter century.

A gold mine of innovation

Laureate Professor Graeme Jameson's contribution to the Australian economy and the environment as the inventor of what is considered by many to be the nation's biggest export earner in the last 25 years, has earned him gold status within the minerals industry and the inaugural Prime Minister's Prize for Innovation in 2015.

Dealing in 'bubbles', Prof Jameson revolutionised a mineral separation process first invented in 1905, to develop the Jameson Cell, a froth flotation device, that has netted Australia more than $36 billion in exports.

Dealing in 'bubbles', Prof Jameson revolutionised a mineral separation process first invented in 1905, to develop the Jameson Cell, a froth flotation device, that has netted Australia more than $36 billion in exports.

Prof Jameson' research continues to push the boundaries and he is currently working on a Fluidised Bed Flotation Cell that has the potential to make massive reductions in the energy used in Australia's minerals industry.

The invention

For many years, Prof Jameson's attention had been focused on improving the effectiveness of extracting valuable minerals from rock.

"I had been looking at ways to improve the flotation process for many years. I knew flotation was important to the Australian industry and felt the answer lay in the mechanics of fluids and particles," Prof Jameson said.

The Jameson Cell is a radically different flotation device that changed the way that minerals were recovered and earned Jameson almost legendary status in mining and engineering circles.

With over 300 cells now in operation across 25 countries, the Cell is being used for copper, coal, zinc, nickel, lead, silver and platinum extraction world-wide.

The process involves grinding mineral ores into small particles, suspending them in water and placing them into stirred tanks known as cells. A large mine can treat 10,000 tonnes an hour – that's similar to 10,000 small cars being reduced to dust every hour.

The Cell works by blowing air bubbles up through the liquid and using reagents to make mineral particles stick to them. The bubbles form a mineral-rich froth on the surface, which is then scraped off.

Saving the environment

As well as recovering billions of dollars' worth of fine coal and minerals a year, the Cell has also been used for industrial and environmental applications including extracting oil from tar sands in Canada, cleaning up industrial wastewaters in Newcastle and other locations in Australia, and removing blue-green algae from waterways in inland Australia.

The finely-ground particles that were once too small to recover and previously were dumped into rivers, or buried, can now be processed. Old mines now have a longer life, and the environmental damage caused by the need open more new mines is reduced.

A core commitment

Jameson's reputation for commitment to an issue was formed early in his career and cemented during his early years at the University of New South Wales.

There he worked as a chemical engineering cadet in Sydney while studying part-time over an eight year period, saving to pay his living expenses to do a PhD at Cambridge University. He arrived at the University of Newcastle as Professor of Chemical Engineering in 1978.

"I see science and technology as agents for improving people's lives. I'm strongly of the view that curiosity-driven research is of great benefit to society, particularly when it is linked, however tenuously, with the solution of a real practical problem," Prof Jameson said.

"As an engineer, my interest is in striving to fix problems that are important to a particular industry, and have previously proven difficult to solve. I like to identify a problem, do the fundamental research into why the current technologies aren't working, and then come up with a practical solution based on the research," he said.

Jameson is held in high esteem by colleagues and researchers in the field of flotation. The Editor of Minerals Engineering, Dr Barry Wills, describes Prof Jameson as a "top class scientist and pioneer in flotation science and practice".

Prof Jameson's services to engineering, science, industry and the environment were recognised when he was awarded an Order of Australia Medal, AO, in 2005. He also was awarded the world's most prestigious award in mineral processing, the Antoine M. Gaudin Medal, in 2013.

Other accolades include the CSIRO Medal and being recognised as a Fellow of the Australian Academy of Sciences, the Royal Academy of Engineering in the UK and the Australian Academy of Technological Sciences.

In the true mark of a scientist, 30 years on from his initial breakthrough discovery, Prof Jameson is still fine-tuning and improving the Jameson Cell.

"I believe that if you're going to put your heart into something, you may as well tackle a problem that will make a difference and benefit the community.

Floating big ideas

At this point in his life, he is not ready to hang up the lab coat. He is now aiming to bring his latest invention, the Fluidised Bed Flotation Cell, to commercial reality. The device will increase the upper particle size limit of flotation and drastically reduce the mining industry's energy and water consumption.

Jameson said he wants to create a "quiet environment' for flotation which, interestingly, seems to be in keeping with his softly-spoken character.

It has been estimated by the CSIRO that the energy used in grinding rock to retrieve valuable material is equal to 14 per cent of Australia's electricity production.

"In this day and age, the amount of valuable material recovered is very small, representing one to two per cent of the feed material, so we are grinding 98 per cent of the feed, only to throw it away," Prof Jameson said.

"To recover particles of copper ore, for example, it is necessary to grind the whole of the feed to the plant, to a top size that is typically 150µm - about the size of a human hair," he said.

"Currently, because the coarse particles are knocked off the bubbles by the violent, turbulent action in the tank, there is a need to grind the particles to a super-fine state.

"My theory is that if we can extract these coarse particles, you won't have to grind so fine and you won't have to expend so much energy."

Jameson likens his new technology to the landscape that Newcastle is famous for - the beach.

"Imagine a bed of sand. If you're well away from the water the sand will be pretty stable and if you stand on it, you don't sink. However, if you go a bit closer to the water you can make the sand fluidise just by moving your feet up and down," he said.

"The sand stays more or less in the same place but the water in the sand is pumped up and down and momentarily it lifts particles away from their neighbours, so the sand becomes liquid-like and you can sink down into it.

"The fluidised bed flotation device uses the same principles by pushing air bubbles through the sediment and this creates a quiet environment for the larger particles to attach to the bubbles."

Prof Jameson recently completed a study that showed that the costs associated with a mine were roughly 43 per cent mining, 43 per cent milling and concentration and 14 per cent general administration. So a significant reduction in the milling costs will have a flow-on effect for the whole mining enterprise.

The Fluidised Bed Flotation Cell is estimated to potentially cut total operating costs of a mining venture, including the mine and the concentrator, by 10 to 20 per cent.

Prof Jameson's next milestone will be to develop an operational pilot plant that can be taken to a mine site for testing.

With a number of prospects still emerging from his latest research, Prof Jameson continues to be a gold mine of innovation for Australian industry.

Watch an interview with Graeme Jameson on 2NUR FM radio station

A gold mine of innovation

Laureate Professor Graeme Jameson's contribution to the Australian economy and the environment as the inventor of what is considered by many to be the nation's biggest export earner in the last 25 years, has earned him gold status within the…

Legacy of leadership

The University's strength in engineering owes much to the work ethic and reputation of its trailblazers.

One need look no further than the University of Newcastle's Centre for Advanced Particle Processing and Transport for proof of the adage 'success breeds success'.

The Centre is renowned for world-leading research into the processing, storage and transport of minerals and industrial products and boasts an outstanding record of commercial and academic achievement. Its research has led to technological advances that have produced multi-million dollar savings for industry, and it is at the forefront of developing new-generation processes that reduce water and energy use.

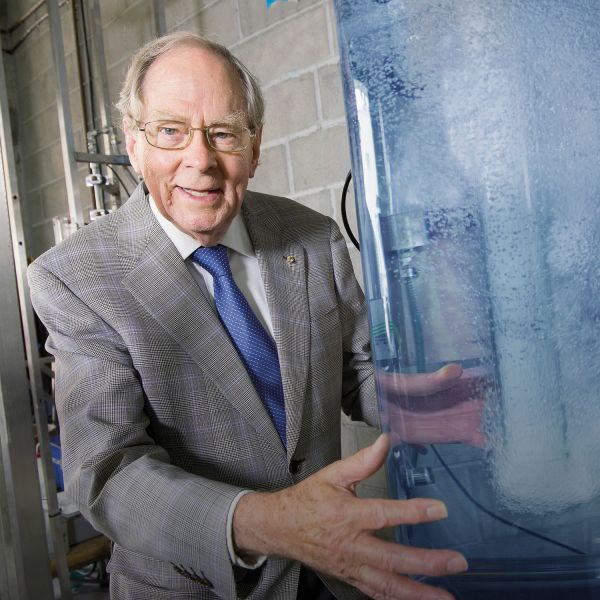

Much of that success is due to the foundation laid by two of the University's elder statesmen and principal researchers in engineering, Laureate Professor Graeme Jameson and Emeritus Professor Alan Roberts.

Both have had long and esteemed careers with the University, Roberts arriving as Professor of Industrial Engineering in 1974 and Jameson as Professor of Chemical Engineering in 1977.

Both have been recognised with Order of Australia awards and have received the prestigious Peter Nicol Russell Memorial Medal from the Institution of Engineers Australia for outstanding service to their profession. Both have also been elected to learned scientific and engineering academies.

Roberts was responsible for the University developing what has become an important and lucrative niche in bulk materials handling, a little-explored area of research back in the 1970s.

He established TUNRA Bulk Solids Handling as a research group and commercial consultancy in 1975. Since then it has completed more than 4000 projects for clients in 40 countries and made an invaluable contribution to research in the field.

"It has become one of the flagships of the University and has certainly validated the decision to go down that path," says Roberts, who is officially retired but still works from his office at the University's Newcastle Institute for Energy Resources (NIER) most days.

"Our work has spanned everything from fine pharmaceutical powders, to plastic powders, agricultural grains, domestic waste and minerals such as iron ore, bauxite and coal. Bulk solids handling is a complex aspect of the industrial process that applies to anything that is transported in powdered or granular form."

Jameson was already a respected expert in fluid mechanics when he came to prominence in the 1980s with his invention of the Jameson Cell. A froth flotation device for recovering fine mineral particles from mine waste and low-yield sources, it was smaller, faster and more precise than existing technology and was quickly taken up by industry.

Jameson was already a respected expert in fluid mechanics when he came to prominence in the 1980s with his invention of the Jameson Cell. A froth flotation device for recovering fine mineral particles from mine waste and low-yield sources, it was smaller, faster and more precise than existing technology and was quickly taken up by industry.

These days there are more than 300 Jameson Cells in operation in 21 countries around the world. As well as recovering billions of dollars worth of fine coal and minerals a year, they are being put to new industrial applications including extracting oil from tar sands in Canada and removing blue-green algae from waterways in central Australia.

"It was one of those 'Eureka!' moments when all the work you have done beforehand comes together in one realisation," Jameson says of the moment he conceived the Cell.

"I was with some students at a mine in Mount Isa and I looked at the equipment they were using and thought, 'I could build something better than that'."

In their early years at the University, both Jameson and Roberts were committed to lifting the research profile of the engineering group, along with another long-time departmental leader Professor Terry Wall.

Their establishment of research centres in multiphase processing, bulk solids handling and black coal utilisation was important both in facilitating the expansion of research and enhancing the status of the University as a leader in those fields.

The University has long been a magnet for talented engineering students, researchers and academics and this is due in no small part to the reputations of Jameson and Roberts.

Find out more

Legacy of leadership

Laureate Professor Graeme Jameson is a world renowned researcher creating the heralded Jameson cell.

Career Summary

Biography

- Chemical Engineering

Qualifications

- PhD, University of Cambridge - UK

- Associate of Sydney Technical College, Sydney Technical College

- Bachelor of Science (Honours)(Chem Engineering), University of New South Wales

Keywords

- Fluid Mechanics

- Mineral Processing

- Surface Chemistry

- chemical engineering

Fields of Research

| Code | Description | Percentage |

|---|---|---|

| 401904 | Mineral processing/beneficiation | 60 |

| 400409 | Separation technologies | 40 |

Professional Experience

Academic appointment

| Dates | Title | Organisation / Department |

|---|---|---|

| Fellow - Royal Australian Chemical Institute | Royal Australian Chemical Institute Australia |

|

| Honorary Fellow - Institution of Engineers, Australia | Institution of Engineers, Australia (IEAus) Australia |

|

| 1/5/2000 - 1/5/2004 | Chair - Selection Committee 5 (Engineering & Applied Science) | Australian Academy of Science |

| 1/1/1975 - | Fellow - Institution of Chemical Engineers | Institution of Chemical Engineers (IChemE) United Kingdom |

| 1/8/1965 - 1/8/1978 | Reader in Chemical Engineering of the University of London | Imperial College of Science & Technology, London Department of Chemical Engineering and Chemical Technology United Kingdom |

Membership

| Dates | Title | Organisation / Department |

|---|---|---|

| Member - Society for Mining, Metallurgy and Exploration (SME) US | Society for Mining, Metallurgy and Exploration (SME) United States |

|

| 8/5/2018 - | Fellow of the Royal Society of London | The Royal Society United Kingdom |

| 6/9/2016 - | Lifetime Achievement Award 2016 | International Mineral Processing Council Canada |

| 6/9/2015 - | Prime Minister's Science Prize for Innovation 2015 | Department of Prime Minister and Cabinet Australia |

| 1/9/2015 - | Foreign Member, US National Academy of Engineering | National Academy of Engineering United States |

| 6/9/2013 - | New South Wales Scientist of the Year 2013 | NSW Department of Premier and Cabinet Australia |

| 6/2/2013 - | Antoine Gaudin Award 2013 | Society of Mining Engineers, Mining and Mineral Processing Division United States |

| 6/1/2005 - | Officer of the Order of Australia | Order of Australia Australia |

| 6/1/2003 - | Ian Wark Medal and Lecture | Australian Academy of Science |

| 6/6/1998 - | K L Sutherland Memorial Medal | ATSE (Australian Academy of Technological Sciences and Engineering) |

| 1/1/1996 - | Fellow - Australian Academy of Science | Australian Academy of Science |

| 1/7/1994 - | Foreign Fellow- Royal Academy of Engineering (UK) | Royal Academy of Engineering United Kingdom |

| 1/1/1992 - 31/12/1994 | Committee Member and Chair - ARC | ARC Engineering Panel Australia |

| 1/1/1991 - | Fellow - Australian Academy of Technological Sciences and Engineering | ATSE (Australian Academy of Technological Sciences and Engineering) |

| 1/1/1990 - | Fellow - Australasian Institute of Mining and Metallurgy | Australasian Institute of Mining and Metallurgy Australia |

Professional appointment

| Dates | Title | Organisation / Department |

|---|---|---|

| 1/1/2014 - 31/12/2016 | ARC Outstanding Researcher Award (DORA Fellowship) | ARC (Australian Research Council) |

Awards

Distinction

| Year | Award |

|---|---|

| 2016 |

Lifetime Achievement Award International Mineral Processing Council |

| 2013 |

Guillaume Delprat Distinguished Lecturer Australasian Institute of Mining and Metallurgy |

| 2013 |

Antoine Gaudin Award Society for Mining, Metallurgy and Exploration (SME) |

| 2013 |

NSW Scientist of the Year Office of the NSW Chief Scientist and Engineer |

| 2004 |

Laureate Professor University of Newcastle |

Honours

| Year | Award |

|---|---|

| 2015 |

Foreign Member, US National Academy of Engineering US National Academy of Engineering |

| 2005 |

Order of Australia in the class of Officer (AO) Council for the Order of Australia |

| 2003 |

Sir Ian Wark Medal and Lecture Australian Academy of Science |

| 2002 |

Centenary Medal Commonwealth |

| 1996 |

Fellow Australian Academy of Science |

| 1994 |

Foreign Fellow Royal Academy of Engineering |

| 1991 |

Fellow ATSE (Australian Academy of Technological Sciences and Engineering) |

Prize

| Year | Award |

|---|---|

| 2015 |

Prime Minister's Science Prize for Innovation Commonwealth Department of Industry Science and Technology |

Recognition

| Year | Award |

|---|---|

| 2014 |

Membership - International Mining Technology Hall of Fame International Mining Technology Hall of Fame |

| 2005 |

Peter Nicol Russell Medal Institution of Engineers Australia (IEAust) |

| 1999 |

President's Medal Australasian Institute of Mining and Metallurgy |

| 1998 |

K L Sutherland Memorial Medal ATSE (Australian Academy of Technological Sciences and Engineering) |

| 1993 |

R K Murphy Medal Royal Australian Chemical Institute |

| 1991 |

Clunies Ross National Science and Technology Award ATSE (Australian Academy of Technological Sciences and Engineering) |

| 1990 |

CSIRO External Research Medal Commonwealth Scientific and Industrial Research Organisation (CSIRO) |

Invitations

Participant

| Year | Title / Rationale |

|---|---|

| 2006 |

Bubbles in Food Organisation: University of Manchester Description: Gave the keynote address on Bubbles and Foams in Food. |

PhD Examiner

| Year | Title / Rationale |

|---|---|

| 2006 |

PhD thesis Organisation: Various Description: In the review period I have reviewed theses from University of Queensland, Sydney, Cape Town |

Publications

For publications that are currently unpublished or in-press, details are shown in italics.

Book (1 outputs)

| Year | Citation | Altmetrics | Link |

|---|---|---|---|

| 2007 | Fuerstenau MC, Jameson GJ, Yoon R-H, Froth Flotation; A Century of Innovation, Society for Mining, Metallurgy, and Exploration, Littleton, CO, 891 (2007) [A3] |

Chapter (8 outputs)

| Year | Citation | Altmetrics | Link | ||

|---|---|---|---|---|---|

| 2014 |

Jameson GJ, 'Jameson Cell Technology for Organics Recovery', Oil Spill Remediation: Colloid Chemistry-Based Principles and Solutions 221-229 (2014) [B1] The separation and recovery of oil that has spilled in the sea poses a number of problems. The first is to capture the oil/water mixture with the minimum amount of clean sea water... [more] The separation and recovery of oil that has spilled in the sea poses a number of problems. The first is to capture the oil/water mixture with the minimum amount of clean sea water. Once this has been done, further problems arise, such as the need to separate the oil from the aqueous medium, in large volumes, at high efficiencies and at an economic cost. Solutions to such problems have been found, and are already in operation in the resource and energy industries. The flotation process, which was initially developed to separate valuable mineral particles from waste material, has been successfully applied to the separation of organics. The Jameson Cell is a specific technology that has found widespread application for the recovery of organics during solvent extraction - electrowinning (SX-EW), and is now being used for recovery of bitumen in the processing of oil sands. The largest single cell in operation can handle 3,000m3/hr (792,000 US gallons/hr), and can readily be adapted to the treatment of oil spill separations. Here, the mechanics of the Jameson Cell are explained, and operational data presented.

|

Nova | |||

| 2007 | Jameson GJ, Nguyen AV, Ata S, 'The flotation of fine and coarse particles', Froth Flotation: A Century of Innovation, Society for Mining, Metallurgy, and Exploration, Englewood, Colorado 339-372 (2007) [B1] | ||||

| 2006 |

Nguyen AV, Pugh RJ, Jameson GJ, 'Collection and Attachment of Particles by Air Bubbles in Froth Flotation', Colloidal Particles at Liquid Interfaces, Cambridge University Press, Cambridge 328-382 (2006) [B1]

|

||||

| 2006 |

Nguyen AV, Evans GM, Jameson GJ, 'Electrical Double-Layer Interaction between Spherical Particles: Appoximate Expressions', Encyclopedia of Surface and Colloid Science, Taylor & Francis, London 1971-1981 (2006) [B1]

|

||||

| 2005 |

Nguyen AV, Phan MC, Evans GM, Jameson GJ, 'Dynamic Adsorption of Surfactants at the Gas-Liquid Interface', Innovations in Natural Resource Processing, Society for Mining, Metallurgy, and Exploration, Englewood, Colorado 87-98 (2005) [B1]

|

Nova | |||

| 2002 |

Nguyen AV, Evans GM, Jameson GJ, 'Approximate expressions for electrical double-layer interaction between spherical particles', Encyclopedia of Surface and Colloid Science, Marcel Dekker Inc., USA 630-641 (2002) [B2]

|

||||

| 2000 | Jameson GJ, 'Flotation', Encyclopedia of Separation Science, Academic Press, London, U.K. 700-710 (2000) [B1] | ||||

| 1999 | Magrabi SA, Dlugogorski BZ, Jameson GJ, 'Ostwald ripening in aqueous foams', Foams and Films, Verlag MIT Bremen, Bremen, Germany 87-95 (1999) [B1] | ||||

| Show 5 more chapters | |||||

Journal article (169 outputs)

| Year | Citation | Altmetrics | Link | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2022 |

Hoque MM, Doroodchi E, Jameson GJ, Evans GM, Mitra S, 'Numerical estimation of critical local energy dissipation rate for particle detachment from a bubble-particle aggregate captured within a confined vortex', Minerals Engineering, 180 (2022) [C1] In flotation, interactions of bubble-particle aggregates with turbulent flow structures in the liquid medium result in particle detachment. This study aims to simulate this phenom... [more] In flotation, interactions of bubble-particle aggregates with turbulent flow structures in the liquid medium result in particle detachment. This study aims to simulate this phenomenon involving a bubble-particle aggregate (bubble diameter ~ 3 mm and particle diameter ~ 314 µm) interacting with a turbulent flow structure manifested as a confined vortex in a square cavity connected to a square cross-section channel. An interface resolved three dimensional (3D) computational fluid dynamics (CFD) model was developed to quantify the bubble-vortex interaction dynamics over a range of channel Reynolds numbers. The CFD model produced a good agreement with the experimentally measured vorticity magnitude, local energy dissipation rate, and bubble motion. It was shown that a bubble-particle aggregate could be captured within the vortex by suitably varying the channel Reynolds number, eventually leading to particle detachment. A separate force balance analysis was performed to determine a criterion for particle detachment utilising the CFD model predicted vorticity and local energy dissipation rate. It was shown that a critical local energy dissipation rate ~ 1.59 m2/s3 was required for particle detachment to occur, which was also verified experimentally.

|

Nova | |||||||||

| 2020 |

Nguyen NN, Chu ATT, Sherman HM, Nguyen AV, Jameson GJ, 'A new paradigm of bubble-particle detachment interaction: How and where do the bubble and the particle detach?', Minerals Engineering, 159 (2020) [C1]

|

Nova | |||||||||

| 2020 |

Jameson GJ, Cooper L, Tang KK, Emer C, 'Flotation of coarse coal particles in a fluidized bed: The effect of clusters', Minerals Engineering, 146 (2020) [C1]

|

Nova | |||||||||

| 2019 |

Gautam S, Jameson GJ, 'The detachment of particles from bubbles at various locations in a turbulent flotation cell', Minerals Engineering, 132 316-325 (2019) [C1]

|

Nova | |||||||||

| 2019 |

Jameson GJ, Emer C, 'Coarse chalcopyrite recovery in a universal froth flotation machine', Minerals Engineering, 134 118-133 (2019) [C1]

|

Nova | |||||||||

| 2018 |

Ng WS, Cooper L, Connal LA, Forbes E, Jameson GJ, Franks GV, 'Tuneable collector/depressant behaviour of xanthate-functional temperature-responsive polymers in the flotation of copper sulfide: Effect of shear and temperature', MINERALS ENGINEERING, 117 91-99 (2018) [C1]

|

Nova | |||||||||

| 2017 |

Bournival G, Ata S, Jameson GJ, 'Bubble and Froth Stabilizing Agents in Froth Flotation', Mineral Processing and Extractive Metallurgy Review, 38 366-387 (2017) [C1]

|

Nova | |||||||||

| 2017 |

Wang G, Evans GM, Jameson GJ, 'Bubble movement in a rotating eddy: The implications for particle-bubble detachment', CHEMICAL ENGINEERING SCIENCE, 161 329-340 (2017) [C1]

|

Nova | |||||||||

| 2017 |

Wang G, Evans GM, Jameson GJ, 'Bubble-particle detachment in a turbulent vortex II-Computational methods', MINERALS ENGINEERING, 102 58-67 (2017) [C1]

|

Nova | |||||||||

| 2016 |

Wang G, Nguyen AV, Mitra S, Joshi JB, Jameson GJ, Evans GM, 'A review of the mechanisms and models of bubble-particle detachment in froth flotation', Separation and Purification Technology, 170 155-172 (2016) [C1] Only when the process of particle detachment is well understood and modelled can minerals recovery using the flotation process be modulated to achieve a high efficiency by suitabl... [more] Only when the process of particle detachment is well understood and modelled can minerals recovery using the flotation process be modulated to achieve a high efficiency by suitably changing the operating parameters. This is vitally necessary for the recovery of coarse particles in an energy efficient way, as detachment is the key limiting factor in the successful recovery of large particles. However, until the detachment mechanism is more fully understood, an upper limit on the floatable particle diameter still remains unidentified. To assess the current state of knowledge available in this area, a comprehensive literature review on the mechanisms and models of the bubble-particle detachment process in froth flotation is presented. In general, the detachment process is considered to be a stochastic process, and is usually attributed to the dynamic interactions with the turbulent flow structures (eddies) in the flotation environment which cause particles to detach because of dissipating energy. In this paper, previous studies on bubble-particle detachment have been critically analyzed with respect to the formulation of the models in predicting the detachment probability of particles. The models are classified into three different categories: force balance analysis; energy balance analysis and empirical analysis of particle size compared to maximum floatable particle size. Attention is also paid to an understanding of the mechanisms of bubble-particle detachment in quiescent and turbulent liquid flow fields. The predictions of all these models have been compared with the published experimental data and it was found that models which take an accurate consideration of the influence of eddies on a particle's detachment give the closest predictions. The generally held concept of bubble-particle detachment inside an eddy was experimentally validated, where a particle was observed to rotate on the surface of a bubble, resulting in a centrifugal acceleration 20 times that of gravitational acceleration. The aim of this paper is to review the developments and limitations of the existing models. The experimental work is reviewed so as to reveal the mechanisms of bubble-particle detachment. Therefore, the future development of models is identified in order to successfully predict particle detachment.

|

Nova | |||||||||

| 2016 |

Wang G, Evans GM, Jameson GJ, 'Experiments on the detachment of particles from bubbles in a turbulent vortex', Powder Technology, 302 196-206 (2016) [C1] In this paper we present a new method for studying the detachment of particles from bubbles in a rotating turbulent eddy. The eddy is formed in a wall cavity in a two-dimensional ... [more] In this paper we present a new method for studying the detachment of particles from bubbles in a rotating turbulent eddy. The eddy is formed in a wall cavity in a two-dimensional water tunnel with transparent walls. When water flows through the tunnel, a vortical flow field develops in the cavity. The properties of the eddy can be modulated by changing the free-stream velocity of the water in the tunnel. Bubbles are pre-loaded with one or more particles in a fluidized bed flotation device located beneath the vortex cavity. Loaded bubbles are released one at a time into the cavity, and the motion of the bubble-particle aggregate is studied using a high-speed video camera. The diameters of the particles and the bubbles, and the number of particles initially attached to the bubble, can be varied. The trajectories taken by the bubbles are quite complicated. In some cases, the bubble moves to the centre of the eddy, and particles rotate around its axis. If the rotational speed is sufficient, particles may detach due to centrifugal force. However, other modes were observed, including inertial detachment due to rapid changes in direction of the surface of the bubble, because of changes in trajectory of the bubble as a whole, or because of pulsations and oscillations of the bubble surface. Clusters of bubbles held together by particles were seen to form and reform. In the traditional explanation for the detachment of particles in flotation cells, it is assumed that particles detach from bubbles rotating in an eddy due to centrifugal force (Schulze, 1977) [1]. Although the conditions assumed in Schulze's theory may exist, it is only one of a range of phenomena that can lead to the detachment of particles from bubbles in a turbulent vortex. The interactions between bubbles and particles is stochastic in nature, and it is impossible to model precisely the series of events that take place when a particle and a bubble make contact with each other and move through the liquid. There can be no simple model for the recovery of hydrophobic particles in flotation machines.

|

Nova | |||||||||

| 2016 |

Wang G, Evans GM, Jameson GJ, 'Bubble-particle detachment in a turbulent vortex I: Experimental', MINERALS ENGINEERING, 92 196-207 (2016) [C1]

|

Nova | |||||||||

| 2015 |

Chen Z, Ata S, Jameson GJ, 'Break-up of bubble clusters in turbulent flow-Theory', Powder Technology, 279 228-232 (2015) [C1] The behaviour of bubble clusters in turbulent conditions has been studied theoretically. The cluster behaviour was modelled based on concept drawn from the related field of bubble... [more] The behaviour of bubble clusters in turbulent conditions has been studied theoretically. The cluster behaviour was modelled based on concept drawn from the related field of bubble breakup. It was assumed that the bubbles were bridged by particles, so the cohesive strength was determined by the capillary force between the bubbles and the particles. Two different theories were investigated for the disruptive force from the turbulent liquid: the shear rate hypothesis of Camp and Stein (1943), and the turbulent fluctuation model arising from Kolmogorov's theory of isotropic turbulence (Kolmogorov, 1941). It was found that neither method is applicable in the fragmentation stage. However, in the equilibrium stage, an equation derived from Camp and Stein's theory was more realistic than that obtained using Kolmogorov's equation.

|

Nova | |||||||||

| 2015 | Jameson G, 'Back to basics: Getting physical', TCE The Chemical Engineer, 44-47 (2015) [C3] | ||||||||||

| 2015 |

Chen Z, Ata S, Jameson GJ, 'Behaviour of bubble clusters in a turbulent flotation cell', Powder Technology, 269 337-344 (2015) [C1] The rate of capture of particles decreases as the particle size increases in froth flotation. It has been postulated that the upper size range of particles that can be recovered i... [more] The rate of capture of particles decreases as the particle size increases in froth flotation. It has been postulated that the upper size range of particles that can be recovered in conventional machines could be extended by the use of bubble clusters [1].This study is concerned with the behaviour of bubble clusters in turbulent flotation cell. The breakup and re-formation of clusters and the effect of bubble size and impeller speed on the behaviour of clusters have been investigated. The apparatus used was essentially a laboratory flotation cell, agitated by a Rushton turbine. The cell was modified to allow pre-formed clusters to rise out of a fluidized bed and into the path of the rotating impeller. The events were captured using a digital camera, and the images were analysed to give the sizes of the bubbles and clusters.In the first part of the investigation, a collector was used but no frother. Under these conditions, the bubble diameter was effectively controlled by the collector concentration, and it varied considerably. It was found that the sizes of clusters decrease with increasing shear rate at low impeller speeds, and at higher speeds the clusters are broken up into bubbles and particles.In the second part, frother was used at a concentration above the critical coalescence concentration, to control the bubble size, which remained essentially constant at this concentration. The bubbles were too small to be broken by the action of the impeller, so they always remained at the same size. In this case it was found that when the impeller speed was increased, two stages of formation were observed, the fragmentation and equilibrium stages. In the fragmentation stage, at low impeller speeds, the clusters were loose and filamentous, and as the energy input increases, they rupture and re-form. In the second stage, above a critical impeller speed, dense clusters formed whose size was relatively insensitive to the energy input.

|

Nova | |||||||||

| 2015 |

Rahman RM, Ata S, Jameson GJ, 'Study of froth behaviour in a controlled plant environment - Part 1: Effect of air flow rate and froth depth', Minerals Engineering, 81 152-160 (2015) [C1] This paper presents the results of a thorough investigation into the froth recovery measurements in a controlled plant environment using a device that allows direct collection of ... [more] This paper presents the results of a thorough investigation into the froth recovery measurements in a controlled plant environment using a device that allows direct collection of dropback particles from the froth phase. Experiments were performed at the Northparkes concentrator (NSW, Australia), using a feed taken from the head of the cleaner scavenger bank. The feed slurry had a relatively higher copper grade varying from 5.2% to 6.8%. Experiments were performed to investigate the effect of important flotation parameters such as air flow rate and froth depth, on the froth performance. The size of the particles in the relevant streams was analysed to acquire in-depth knowledge about the froth dropback mechanism. The results suggested that the froth recovery could be as low as 70%, although it was relatively easy to achieve the values in the range 75-85% by the correct choice of operating variables. It was found that the air flow rate has a positive impact on both collection (pulp) and froth zone recoveries. However, the effect was more prominent in the froth zone. It appeared that the froth recovery is a strong function of particle size.

|

Nova | |||||||||

| 2015 |

Rahman RM, Ata S, Jameson GJ, 'Study of froth behaviour in a controlled plant environment - Part 2: Effect of collector and frother concentration', Minerals Engineering, 81 161-166 (2015) [C1] An investigation into froth zone recovery in a controlled plant environment is presented. The effect of operating conditions on the froth performance is given in our previous work... [more] An investigation into froth zone recovery in a controlled plant environment is presented. The effect of operating conditions on the froth performance is given in our previous work (Rahman et al., 2015). This paper is primarily concerned with the influence of chemical properties such as frother and collector concentration on the froth behaviour. The results suggested that increasing the collector concentration gave expected results in the collection (pulp) zone, with a significant increase in coarse particle recovery. However, at high collector concentrations, it was observed that there was an increase in bubble coalescence and froth instability as well as a slight decrease in froth recovery. Increasing frother concentration gave a significant improvement in froth recovery and a slight increase in the collection zone recovery was also found. This was attributed to the formation of finer, more stable, bubbles and a corresponding increase in froth stability. Size and grade analysis of the samples suggested that the dropback particles were mainly composite or middling fractions. It appeared that particles whose grade was higher than the feed may be collected into the froth zone, but some particles with grades lower than the concentrate may detach from the froth.

|

Nova | |||||||||

| 2015 |

Chen Z, Ata S, Jameson GJ, 'Breakup and re-formation of bubble clusters in a flotation cell', Minerals Engineering, 71 16-20 (2015) [C1] This study is concerned with the behavior of bubble clusters in a well-controlled turbulent flow. We used a specially designed cell where the bubble aggregates could be formed and... [more] This study is concerned with the behavior of bubble clusters in a well-controlled turbulent flow. We used a specially designed cell where the bubble aggregates could be formed and exposed to breakage by a rotating impeller. The effects of impeller speed and the concentration of collector on cluster behavior were studied. It was found that the size of the clusters increases with the concentration of collector used. We also found that although the clusters could easily be destroyed under the action of impeller, they could reform, especially at lower impeller speeds. It was observed that the size of the bubbles arriving into the impeller region in the absence of particles before breakage was considerably higher than the size of the clusters formed at the same impeller speed. It appears that both cluster breakage and re-formation take place simultaneously, and the extent of formation and regrowth is mainly determined by the hydrophobicity of the particles and the impeller speed.

|

Nova | |||||||||

| 2014 |

Bournival G, Du Z, Ata S, Jameson GJ, 'Foaming and gas dispersion properties of non-ionic frothers in the presence of hydrophobized submicron particles', INTERNATIONAL JOURNAL OF MINERAL PROCESSING, 133 123-131 (2014) [C1]

|

Nova | |||||||||

| 2014 |

Wang G, Zhou S, Joshi JB, Jameson GJ, Evans GM, 'An energy model on particle detachment in the turbulent field', Minerals Engineering, 69 165-169 (2014) [C1] A flotation detachment model is developed by considering energy balance in the process. Energies concerned are surface energy increment and kinetic energy supplied by turbulent li... [more] A flotation detachment model is developed by considering energy balance in the process. Energies concerned are surface energy increment and kinetic energy supplied by turbulent liquid motion. Surface energy increment is the work of adhesion by surface forces which is reflected by surface tension and contact angle. What makes this model outstanding from other detachment models of energy balance perspective is more accurate account of kinetic energy supplied from turbulent liquid motion. Eddies in the same scale as attached particles are considered accountable for particle detachment in the close vicinity. In this way, detachment probability is written as a function of energy dissipation rate. Predictions from different models are compared to experimental results. It is demonstrated that previous models overestimate the influence from turbulent liquid motion. Notably, with more accurate account of eddies' influence, the new model predicts particle detachment in accordance with experimental results.

|

Nova | |||||||||

| 2014 |

Bournival G, Ata S, Jameson GJ, 'The influence of submicron particles and salt on the recovery of coarse particles', Minerals Engineering, 69 146-153 (2014) [C1] Coarse particles are more difficult to float. One of the factors that contributes to poor floatability is the stability of froth. The froth formed in industrial flotation cells is... [more] Coarse particles are more difficult to float. One of the factors that contributes to poor floatability is the stability of froth. The froth formed in industrial flotation cells is typically not strong enough to provide adequate support for coarse and dense particles. The present study investigates how the presence of hydrophobic submicron particles at low concentration increases the recovery of relatively coarse particles through improvement in the froth stability. Silica particles with d80 of approximately 230 µm were floated in a laboratory mechanical flotation cell in a collector-free environment in the presence of poly(propylene glycol) 425 as a frothing agent. The hydrophobicity of the feed particles was modified through an esterification process with different alcohols ranging from 3 to 8 hydrocarbon groups to form a coating of intermediate hydrophobicity. Hydrophobised silica submicron particles of 300 nm in size were added to the flotation cell at 0.01 and 0.1 wt% concentration. The effect of electrolyte, sodium chloride, in the concentration range 10-5-10-1 M on the recovery of coarse particles was also investigated. For the feed employed, 1-butanol was found to provide relatively good flotation properties with a possibility for improvement by stabilising the froth phase. Both additives slightly stabilised the froth phase, which resulted in an increase in the maximum recovery of up to approximately 8%. It appeared that the additives had no significant effect on the first-order flotation rate constant.

|

Nova | |||||||||

| 2014 |

Wang G, Sathe M, Mitra S, Jameson GJ, Evans GM, 'Detachment of a bubble anchored to a vertical cylindrical surface in quiescent liquid and grid generated turbulence', Canadian Journal of Chemical Engineering, 92 2067-2077 (2014) [C1] Turbulence plays a critical role in detachment process of bubble from a solid surface. To investigate this effect, detachment process of a stationary air bubble from a nozzle in b... [more] Turbulence plays a critical role in detachment process of bubble from a solid surface. To investigate this effect, detachment process of a stationary air bubble from a nozzle in both quiescent and turbulent liquid field was studied. A stationary vertical (flat-ended) needle of ID 1.24mm was used as a nozzle to generate a bubble which was anchored to the needle tip. Different sizes of bubbles were generated in quiescent liquid. Volume and contact angle for these bubbles were measured precisely using microscopic imaging technique and correlated. In the quiescent case experiments, a constant contact angle of 90° and bubble diameter of 3.05±0.004mm were obtained consistently. A simple force balance approach was proposed assuming bubble in equilibrium to determine this maximum bubble diameter during detachment. The detached bubble size calculated using this approach agreed fairly well with the experimental results. An oscillating grid device capable of operating at different frequencies was then applied to generate a homogeneous, near-isotropic turbulent velocity field around the anchored bubble. It was observed that for detachment of smaller bubbles, higher turbulence intensity was indeed necessary. The turbulent flow field was quantified using particle image velocimetry (PIV) technique and resolved into flow structures (eddies) of different length scales using a Gaussian filter. It was concluded that smaller eddies perturbed the bubble interface whilst the larger eddies contributed to weakening of the capillary force causing the bubble detachment. Energy dissipation profile obtained from the PIV images indicated significant energy dissipation near the bubble compared to the bulk fluid which supported the fact that strong interactions between bubble and eddies were indeed responsible for bubble detachment.

|

Nova | |||||||||

| 2014 |

Bournival G, Ata S, Karakashev SI, Jameson GJ, 'An investigation of bubble coalescence and post-rupture oscillation in non-ionic surfactant solutions using high-speed cinematography', JOURNAL OF COLLOID AND INTERFACE SCIENCE, 414 50-58 (2014) [C1]

|

Nova | |||||||||

| 2014 |

Ireland PM, Jameson GJ, 'Collision of a rising bubble-particle aggregate with a gas-liquid interface', International Journal of Mineral Processing, 130 1-7 (2014) [C1] In this paper we investigate the hypothesis that when bubbles carrying attached hydrophobic particles arrive at an air-liquid interface, the abrupt change in velocity is sufficien... [more] In this paper we investigate the hypothesis that when bubbles carrying attached hydrophobic particles arrive at an air-liquid interface, the abrupt change in velocity is sufficient to dislodge attached particles, which fall back into the liquid. For the first time, experiments have demonstrated a case in which the particles do not detach, but move smoothly over the surface of the bubbles. The kinetic energy of arrival is dissipated by the motion of the particles through the liquid, as they move over the surface of the bubble while remaining attached. Some energy is also dissipated by the pulsations of the bubbles. The pulsations themselves do not lead to detachment of particles. A theory has been developed to explain the observed phenomena. © 2014 Published by Elsevier B.V.

|

Nova | |||||||||

| 2014 |

Curry JA, Ismay MJL, Jameson GJ, 'Mine operating costs and the potential impacts of energy and grinding', Minerals Engineering, 56 70-80 (2014) [C1] An understanding of the breakdown of mine costs is an important tool for researchers and developers who seek to place novel cost-reducing unit operations in the wider general cost... [more] An understanding of the breakdown of mine costs is an important tool for researchers and developers who seek to place novel cost-reducing unit operations in the wider general cost context. This paper provides a breakdown of operating costs in 63 mines by dividing them into three main categories: mining, milling, and general and administrative (G & A) costs. The study looks at patterns in mining type, mill processing type, mineral type, and the differences between costs expressed in feasibility studies vs. operating mines. The paper explores the reasons for the relationships observed and then presents a total average mine cost breakdown. It was found that the mean relative mining and milling costs did not differ significantly, and that on average they had equal shares of the total enterprise operating costs. Effects of mine and mineral type were observed, with underground milling costs being significantly less than open pit milling costs and gold mines occupying a significantly larger share of mine operating costs than copper-containing mines. The overall relative operating costs were found to be in the ratios between (43:43:14) and (45:45:10) (Mine:Mill:G & A). A treatment of potential unit operations and innovative technologies is provided at the conclusion of the paper, including coarse particle recovery by flotation and novel grinding technologies. © 2013 Published by Elsevier Ltd.

|

Nova | |||||||||

| 2014 |

Bournival G, Du Z, Ata S, Jameson GJ, 'Foaming and gas dispersion properties of non-ionic surfactants in the presence of an inorganic electrolyte', Chemical Engineering Science, 116 536-546 (2014) [C1] Foams represent an important area of research due to their relevance in many industrial processes. Where there are geographical constraints, which can limit access to fresh water,... [more] Foams represent an important area of research due to their relevance in many industrial processes. Where there are geographical constraints, which can limit access to fresh water, there is an economic incentive in using recycled water, bore water and even seawater for industrial purposes. This creates a growing interest in determining the effect of inorganic electrolytes on foaming and gas dispersion properties of non-ionic surfactant solutions. The present study compares the foaming and gas dispersion properties of the non-ionic surfactants 1-pentanol, tri(propylene glycol) methyl ether, and poly(propylene glycol) 425. For all surfactants, the stabilisation mechanism was influenced by the concentration of surfactant and the presence of salt with PPG being affected to a lesser extent. Sodium chloride was observed to have a detrimental effect on foaming at higher surfactant concentrations but improved foaming at low surfactant concentrations. At low surfactant concentrations, the addition of salt improved foaminess by dampening the hydrophobic force. An increase in gas holdup with increasing surfactant concentration was observed and was attributed to a decrease in bubble size. For poly(propylene glycol) an initial decrease in gas holdup was observed at very low concentrations. Salt mainly affected gas dispersion properties at a higher concentration. © 2014 Elsevier Ltd.

|

Nova | |||||||||

| 2013 |

Ireland PM, Jameson GJ, 'Particle dynamics in cyclone tribochargers', JOURNAL OF ELECTROSTATICS, 71 449-455 (2013) [C1]

|

Nova | |||||||||

| 2013 |

Ata S, Jameson GJ, 'Recovery of coarse particles in the froth phase - A case study', MINERALS ENGINEERING, 45 121-127 (2013) [C3]

|

||||||||||

| 2012 |

Neville FC, Mohd Zin AB, Jameson GJ, Wanless EJ, 'Preparation and characterization of colloidal silica particles under mild conditions', Journal of Chemical Education, 89 940-942 (2012) [C1]

|

Nova | |||||||||

| 2012 |

Ireland PM, Jameson GJ, 'Drag force on a spherical particle moving through a foam: The role of wettability', International Journal of Mineral Processing, 102-103 78-88 (2012) [C1]

|

Nova | |||||||||

| 2012 |

Rahman RM, Ata S, Jameson GJ, 'The effect of flotation variables on the recovery of different particle size fractions in the froth and the pulp', International Journal of Mineral Processing, 106 70-77 (2012) [C1]

|

Nova | |||||||||

| 2012 |

Jameson GJ, 'The effect of surface liberation and particle size on flotation rate constants', Minerals Engineering, 36-38 132-137 (2012) [C1]

|

Nova | |||||||||

| 2012 |

Gautam A, Jameson GJ, 'The capillary force between a bubble and a cubical particle', Minerals Engineering, 36-38 291-299 (2012) [C1]

|

Nova | |||||||||

| 2012 |

Goel S, Jameson GJ, 'Detachment of particles from bubbles in an agitated vessel', Minerals Engineering, 36-38 324-330 (2012) [C1]

|

Nova | |||||||||

| 2012 |

Moberg AK, Ellem GK, Jameson GJ, Herbertson JG, 'Simulated cell trajectories in a stratified gas-liquid flow tubular photobioreactor', Journal of Applied Phycology, 24 357-363 (2012) [C1]

|

Nova | |||||||||

| 2011 |

Ata S, Pugh RJ, Jameson GJ, 'The influence of interfacial ageing and temperature on the coalescence of oil droplets in water', Colloids and Surfaces A: Physicochemical and Engineering Aspects, 374 96-101 (2011) [C1]

|

Nova | |||||||||

| 2010 |

Jameson GJ, 'Advances in fine and coarse particle flotation', Canadian Metallurgical Quarterly, 49 328-330 (2010) [C1]

|

Nova | |||||||||

| 2010 |

Button EC, Davidson JF, Jameson GJ, Sader JE, 'Water bells formed on the underside of a horizontal plate. Part 2. Theory', Journal of Fluid Mechanics, 649 45-68 (2010) [C1]

|

Nova | |||||||||

| 2010 |

Jameson GJ, Jenkins CE, Button EC, Sader JE, 'Water bells formed on the underside of a horizontal plate. Part 1. Experimental investigation', Journal of Fluid Mechanics, 649 19-43 (2010) [C1]

|

Nova | |||||||||

| 2010 |

Jameson GJ, 'New directions in flotation machine design', Minerals Engineering, 23 835-841 (2010) [C1]

|

Nova | |||||||||

| 2009 |

Ireland PM, Jameson GJ, 'Foam slip on surfaces of intermediate or low wettability', Chemical Engineering Science, 64 3859-3867 (2009) [C1]

|

Nova | |||||||||

| 2009 |

Zhou Y, Yu H, Wanless EJ, Jameson GJ, Franks GV, 'Influence of polymer charge on the shear yield stress of silica aggregated with adsorbed cationic polymers', Journal of Colloid and Interface Science, 336 533-543 (2009) [C1]

|

Nova | |||||||||

| 2009 |

Hunter TN, Jameson GJ, Wanless EJ, Dupin D, Armes SP, 'Adsorption of submicrometer-sized cationic sterically stabilized polystyrene latex at the air-water interface: Contact angle determination by ellipsometry', Langmuir, 25 3440-3449 (2009) [C1]

|

Nova | |||||||||

| 2009 |

Hunter TN, Wanless EJ, Jameson GJ, 'Effect of esterically bonded agents on the monolayer structure and foamability of nano-silica', Colloids and Surfaces A: Physicochemical and Engineering Aspects, 334 181-190 (2009) [C1]

|

Nova | |||||||||

| 2009 |

Hunter TN, Wanless EJ, Jameson GJ, Pugh RJ, 'Non-ionic surfactant interactions with hydrophobic nanoparticles: Impact on foam stability', Colloids and Surfaces A: Physicochemical and Engineering Aspects, 347 81-89 (2009) [C1]

|

Nova | |||||||||

| 2008 | Jameson GJ, Jenkins C, Button EC, Sader JE, 'Water bells created from below', Physics of Fluids, 20 091108 (2008) [C3] | Nova | |||||||||

| 2008 |

Hunter TN, Pugh RJ, Franks GV, Jameson GJ, 'The role of particles in stabilising foams and emulsions', Advances in Colloid and Interface Science, 137 57-81 (2008) [C1]

|

Nova | |||||||||

| 2008 |

Olsen AH, Franks GV, Biggs S, Jameson GJ, 'Collision efficiency factor for heteroaggregation: Extension to soft interactions', Journal of Chemical Physics, 128 044913 (2008) [C1]

|

Nova | |||||||||

| 2008 |

Zhou Y, Gan Y, Wanless EJ, Jameson GJ, Franks GV, 'Interaction forces between silica surfaces in aqueous solutions of cationic polymeric flocculants: Effect of polymer charge', Langmuir, 24 10920-10928 (2008) [C1]

|

Nova | |||||||||

| 2008 |

Yates PD, Franks GV, Jameson GJ, 'Orthokinetic heteroaggregation with nanoparticles: Effect of particle size ratio on aggregate properties', Colloids and Surfaces A: Physicochemical and Engineering Aspects, 326 83-91 (2008) [C1]

|

Nova | |||||||||

| 2008 |

Zhou Y, Jameson GJ, Franks GV, 'Influence of polymer charge on the compressive yield stress of silica aggregated with adsorbed cationic polymers', Colloids and Surfaces A: Physicochemical and Engineering Aspects, 331 183-194 (2008) [C1]

|

Nova | |||||||||

| 2007 |

Ireland PM, Cunningham R, Jameson GJ, 'The behaviour of wash water injected into a froth', International Journal of Mineral Processing, 84 99-107 (2007) [C1]

|

||||||||||

| 2007 |

Hunter TN, Jameson GJ, Wanless EJ, 'Determination of contact angles of nanosized silica particles by multi-angle single-wavelength ellipsometry', Australian Journal of Chemistry, 60 651-655 (2007) [C1]

|

Nova | |||||||||

| 2007 |

Ireland PM, Jameson GJ, 'Liquid transport in a coalescing froth', Canadian Journal of Chemical Engineering, 85 654-661 (2007) [C1]

|

||||||||||

| 2007 |

Jameson GJ, Parekh VV, 'Effect of n-alcohols on the stability of bubbles', Canadian Metallurgical Quarterly, 46 311-320 (2007) [C1]

|

||||||||||

| 2007 |

Ireland PM, Jameson GJ, 'Liquid transport in a multi-layer froth', Journal of Colloid and Interface Science, 314 207-213 (2007) [C1]

|

Nova | |||||||||

| 2007 |

Stevenson P, Jameson GJ, 'Modelling continuous foam fractionation with reflux', Chemical Engineering and Processing: Process Intensification, 46 1286-1291 (2007) [C1]

|

||||||||||

| 2006 |

Olsen AH, Franks GV, Biggs S, Jameson GJ, 'An improved collision efficiency model for particle aggregation', Journal of Chemical Physics, 125 (2006) [C1]

|

||||||||||

| 2006 |

Jameson GJ, 'Selected papers from the Centenary of Flotation Symposium, 5-9 June 2005, Brisbane, Australia - Foreword', MINERALS ENGINEERING, 19 529-530 (2006)

|

||||||||||

| 2006 |

Nguyen AV, Alexandrova L, Grigorov L, Jameson GJ, 'Dewetting kinetics on silica substrates: Three phase contact expansion measurements for aqueous dodecylammonium chloride films', Minerals Engineering, 19 651-658 (2006) [C1]

|

||||||||||

| 2006 |

Ata S, Pigram SM, Jameson GJ, 'Tracking of particles in the froth phase: An experimental technique', Minerals Engineering, 19 824-830 (2006) [C1]

|

||||||||||

| 2006 | Jameson GJ, 'Minerals Engineering: Foreword (editorial)', Minerals Engineering, 19 529-530 (2006) [C3] | ||||||||||

| 2006 | Jameson GJ, 'Selected papers from the Centenary of Flotation Symposium, 5-9 June 2005, Brisbane, Australia', Minerals Engineering, 19 340 (2006) [C2] | ||||||||||

| 2006 |

Franks GV, Sepulveda CV, Jameson GJ, 'PH-sensitive flocculation: Settling rates and sediment densities', AICHE Journal, 52 2774-2782 (2006) [C1]

|

||||||||||

| 2006 |

Nguyen AV, George PF, Jameson GJ, 'Demonstration of a minimum in the recovery of nanoparticles by flotation: Theory and experiment', Chemical Engineering Science, 61 2494-2509 (2006) [C1]

|

Nova | |||||||||

| 2005 |

Olsen AH, Franks GV, Biggs S, Jameson GJ, 'Bi-modal Hetro-aggregation Rate Response to Particle Dosage', Journal of Chemical Physics, 123 - (2005) [C1]

|

Nova | |||||||||

| 2005 |

Franks GV, Yates PD, Lambert NW, Jameson GJ, 'Aggregate size and density after shearing, implications for dewatering fine tailings with hydrocyclones', International Journal of Mineral Processing, 77 46-52 (2005) [C1]

|

Nova | |||||||||

| 2005 |

Nguyen AV, Jameson GJ, 'Sliding of fine particles on the slip surface of rising gas bubbles: Resistance of liquid shear flows', International Journal of Multiphase Flow, 31 492-513 (2005) [C1]

|

||||||||||

| 2005 |

Ata S, Jameson GJ, 'The formation of bubble clusters in flotation cells', International Journal of Mineral Processing, 76 123-139 (2005) [C1]

|

Nova | |||||||||

| 2005 |

Harvey PA, Nguyen AV, Jameson GJ, Evans GM, 'Influence of sodium dodecyl sulphate and Dowfroth frothers on froth stability', Minerals Engineering, 18 311-315 (2005) [C1]

|

Nova | |||||||||

| 2005 |

Yates PD, Franks GV, Biggs S, Jameson GJ, 'Heteroaggregation with nanoparticles: effect of particle size ratio on optimum particle dose', Colloids and Surfaces a-Physicochemical and Engineering Aspects, 255 85-90 (2005) [C1]

|

||||||||||

| 2005 |

Evans GM, Manning SA, Jameson GJ, 'Cavity formation, growth, and dispersion behind rotating impeller blades', Industrial & Engineering Chemistry Research, 44 6304-6309 (2005) [C1]

|

Nova | |||||||||

| 2005 |

Ata S, Pigram S, Jameson GJ, 'Tracking of particles in the froth phase - an experimental technique', Australasian Institute of Mining and Metallurgy Publication Series, 309-313 (2005) This paper is concerned with the tracking of particles in the froth phase of an aerated water/glycerol mixture. Experiments have been carried out in a specially designed laborator... [more] This paper is concerned with the tracking of particles in the froth phase of an aerated water/glycerol mixture. Experiments have been carried out in a specially designed laboratory flotation cell that allows formation of a deep froth. Phosphorescent tracer particles of various sizes were injected into the centre of a froth column where they were excited by ultraviolet lights, positioned at the back and front of the column. The motion of particles was captured on a digital camera with a green filter. The images from the digital camera were then transferred to a computer and an image analysis program was used to convert the colour intensity to the concentration of particles at each location within the froth. The tracer technique was used to determine the dispersion of hydrophilic particles and the variation of the concentration of solids with axial and radial positions. |

||||||||||

| 2005 |

Ata S, Agarwal A, Jameson GJ, 'The Formation of Bubble Clusters in Flotation Cells - Effect of Impeller Speed', Australasian Institute of Mining and Metallurgy Publication Series, 403-406 (2005) This paper is concerned with the observation and analysis of bubble clusters in a laboratory flotation cell. A device was used in which bubbles were allowed to rise in clean water... [more] This paper is concerned with the observation and analysis of bubble clusters in a laboratory flotation cell. A device was used in which bubbles were allowed to rise in clean water containing the same frother and collector concentration as in the cell. Bubble clusters were recorded using a high speed camera and analysed using an image analyser. Dodecyl amine was employed as a collector to float silica. The effect of impeller speed on the cluster behaviour was investigated. The results were interpreted in terms of cluster diameter and shape factor. The sizes of the bubbles forming the clusters were also measured and compared to the sizes of the independent bubbles in the cell. It was found that there was an optimum impeller speed in which the cluster diameter was a maximum. Higher agitation and the consequent higher power inputs resulted in cluster break-up while lower shear rates promoted cluster formation. |

||||||||||

| 2005 |

Alexandrova L, Nguyen AV, Grigorov L, Jameson GJ, 'Dewetting kinetics on silica substrates - three-phase contact expansion measurements for aqueous dodecylammonium chloride films', Australasian Institute of Mining and Metallurgy Publication Series, 397-402 (2005) The dewetting kinetics between a small air-liquid interface and a silica (negatively charged in water) planar surface in solutions of dodecylammonium chloride (cationic surfactant... [more] The dewetting kinetics between a small air-liquid interface and a silica (negatively charged in water) planar surface in solutions of dodecylammonium chloride (cationic surfactant) has been investigated using the Scheludko cell and digital high-speed video microscopy. The gas-liquid interface was created at the bottom of a small silica capillary of the cell and then was moved towards the silica planar surface. After the rupture of the liquid films between the interfaces, the expansion of the gas-liquid-solid three-phase contact (TPC) line was observed and recorded using a digital high-speed video microscope system, operating at 1000 frames per second. The surface tension of the surfactant solution was measured using the pendant drop technique. The equilibrium contact angle was measured using the Scheludko-Minings method with a silica micro-sphere. The TPC radius was determined as a function of time and compared against the available hydrodynamic and molecular-kinetic models. The experimental data are described very well by the molecular-kinetic model for the TPC line motion. The hydrodynamic model is in agreement with the experimental data only for a short time after inception of the three-phase contact expansion. |

||||||||||

| 2004 |

Yan Y, Jameson GJ, 'Application of the Jameson Cell technology for algae and phosphorus removal from maturation ponds', Int. Journal of Mineral Processing, 73 23-28 (2004) [C1]

|

||||||||||

| 2004 |

Yan Y, Glover SM, Jameson GJ, Biggs SR, 'The flocculation efficiency of polydisperse polymer flocculants', Int. Journal of Mineral Processing, 73 161-175 (2004) [C1]

|

||||||||||

| 2004 |

Glover SM, Yan Y, Jameson GJ, Biggs SR, 'Dewatering properties of dual-polymer-flocculated systems', Int. Journal of Mineral Processing, 73 145-160 (2004) [C1]

|

||||||||||

| 2004 |

Ata S, Ahmed N, Jameson GJ, 'The effect of hydrophobicity on the drainage of gangue minerals in flotation froths', Minerals Engineering, 17 897-901 (2004) [C1]

|

||||||||||

| 2004 |

George PF, Nguyen AV, Jameson GJ, 'Assessment of true flotation and entrainment in the flotation of submicron particles by fine bubbles', Minerals Engineering, 17 847-853 (2004) [C1]

|

||||||||||

| 2004 |

Franks GV, Zhou Y, Yan Y, Jameson GJ, Biggs SR, 'Effect of aggregate size on sediment bed rheological properties', Physical Chemistry Chemical Physics, 6 4490-4498 (2004) [C1]

|

Nova | |||||||||

| 2003 |

Atkinson B, Jameson GJ, Nguyen AV, Evans GM, Machniewski PM, 'Bubble Breakup and Coalescence in a Plunging Liquid Jet bubble Column', The Canadian Journal of Chemical Engineering, 81 519-527 (2003) [C1]

|

||||||||||

| 2003 |

Stevenson P, Sullivan SP, Jameson GJ, 'Short-time tracer dispersion in a two-dimensional rising froth', Chemical Engineering Science, 58 5025-5043 (2003) [C1]

|

||||||||||

| 2003 |

Atkinson B, Jameson GJ, Nguyen AV, Evans GM, 'Increasing Gas - Liquid Contacting Using a Confined Plunging Liquid Jet', Journal of Chemical Technology and Biotechnology, 78 269-275 (2003) [C1]

|

||||||||||

| 2003 |

Ata S, Ahmed N, Jameson GJ, 'A Study of bubble Coalescence in Flotation Froths', International Journal of Mineral Processing, 72 255-266 (2003) [C1]

|

Nova | |||||||||

| 2003 |

Phan MC, Nguyen AV, Miller JD, Evans GM, Jameson GJ, 'Investigations of Bubble-Particle Interactions', International Journal of Mineral Processing, 72 239-254 (2003) [C1]

|

||||||||||

| 2003 |

Nguyen AV, Harvey PA, Jameson GJ, 'Influence of Gas Flow Rate and Frothers on Water Recovery in a Froth Column', Minerals Engineering, 16 1143-1147 (2003) [C1]

|

||||||||||

| 2003 |

Stevenson P, Stevanov C, Jameson GJ, 'Liquid Overflow from a Column of Rising Aqueous Froth', Minerals Engineering, 16 1045-1053 (2003) [C1]

|

||||||||||

| 2003 |

Burns JL, Yan Y, Jameson GJ, Biggs SR, 'The Rheology of Concentrated Suspensions of Depletion-Flocculated Latex Particles', Colloids and Surfaces A, 214 173-180 (2003) [C1]

|

Nova | |||||||||

| 2002 |

Burns JL, Yan Y, Jameson GJ, Biggs S, 'The effect of molecular weight of nonadsorbing polymer on the structure of depletion-induced flocs', Journal of Colloid and Interface Science, 247 24-32 (2002) [C1]

|

Nova | |||||||||

| 2002 |

Biggs SR, Burns JL, Yan Y, Jameson G, Jenkins P, 'Viscosity effect on the structural compactness of latex flocs formed under weak depletion attractions', Journal of Colloid and Interface Science, 255 91-97 (2002) [C1]

|

||||||||||

| 2002 |

Ata S, Ahmed N, Jameson GJ, 'Collection of hydrophobic particles in the froth phase', International Journal of Mineral Processing, 64 101-122 (2002) [C1]

|

Nova | |||||||||

| 2002 |

Magrabi SA, Dlugogorski BZ, Jameson GJ, 'A comparative study of drainage characteristics in AFFF and FFFP compressed-air fire-fighting foams', Fire Safety Journal, 37 21-52 (2002) [C1]

|

||||||||||

| 2001 |

Magrabi SA, Dlugogorski BZ, Jameson GJ, 'Free drainage in aqueous foams: model and experimental study', AIChE Journal, 47 No. 2 314-327 (2001) [C1]

|

||||||||||

| 2000 |

Nguyen AV, Evans GM, Jameson GJ, 'Simple approximate expressions for electrical double-layer interaction at constant moderate potentials', Journal of Colloid and Interface Science, 230 205-209 (2000) [C1]

|

||||||||||

| 2000 |

Gardiner BS, Dlugogorski BZ, Jameson GJ, 'Coarsening of two and three dimensional wet polydisperse foams', Phil. Mag. A, 80 (4) 981-1000 (2000) [C1]

|

||||||||||

| 2000 |

Farmer AD, Collings AF, Jameson GJ, 'Effect of ultrasound on surface cleaning of silica particles', Int. J. Mineral Processing, 60 101-113 (2000) [C1]

|

||||||||||

| 2000 |

Gardiner BS, Dlugogorski BZ, Jameson GJ, 'The steady shear of three-dimensional wet polydisperse foams', J. Non-Newt. Fluid Mech., 92 151-166 (2000) [C1]

|

||||||||||

| 2000 |

Magrabi SA, Dlugogorski BZ, Jameson GJ, 'The performance of aged aqueous foams for mitigation of thermal radiation', Dev.Chem.Eng.Mineral Process, 8 93-112 (2000) [C1]

|

||||||||||

| 2000 |

Biggs S, Habgood MG, Jameson GJ, Yan Y, 'Aggregate structures formed via a bridging flocculation mechanism', Chemical Engineering Journal, 80 13-22 (2000) [C1]

|

||||||||||

| 2000 |

Glover SM, Yan Y, Jameson GJ, Biggs S, 'Bridging flocculation studied by light scattering and settling', Chemical Engineering Journal, 80 3-12 (2000) [C1]

|

||||||||||

| 2000 |

Yan Y, Burns JL, Jameson GJ, Biggs S, 'The structure and strength of depletion-force induced particle aggregates', Chemical Engineering Journal, 80 23-30 (2000) [C1]

|

||||||||||

| 2000 |

Biggs S, Burns JL, Yan Y, Jameson GJ, Jenkins P, 'Molecular weight dependence of the depletion interaction between silica surfaces in solutions of sodium poly(styrene sulfonate)', Langmuir, 16 9242-9248 (2000) [C1]

|

||||||||||

| 2000 |

Nguyen AV, Evans GM, Jameson GJ, 'Erratum: Simple approximate expressions for electrical double-layer interaction at constant moderate potentials (Journal of Colloid and Interface Science (2000) 1:230 (205-209))', Journal of Colloid and Interface Science, 232 414 (2000)

|

||||||||||

| 1999 |

Magrabi SA, Dlugogorski BZ, Jameson GJ, 'Bubble size distribution and coarsening of aqueous foams', Chemical Engineering Science, 54 4007-4022 (1999) [C1]

|

||||||||||

| 1999 |

Gardiner BS, Dlugogorski BZ, Jameson GJ, 'Prediction of pressure losses in pipe flow of aqueous foams', Industrial & Engineering Chemistry Research, 38 1099-1106 (1999) [C1]

|

||||||||||

| 1999 |